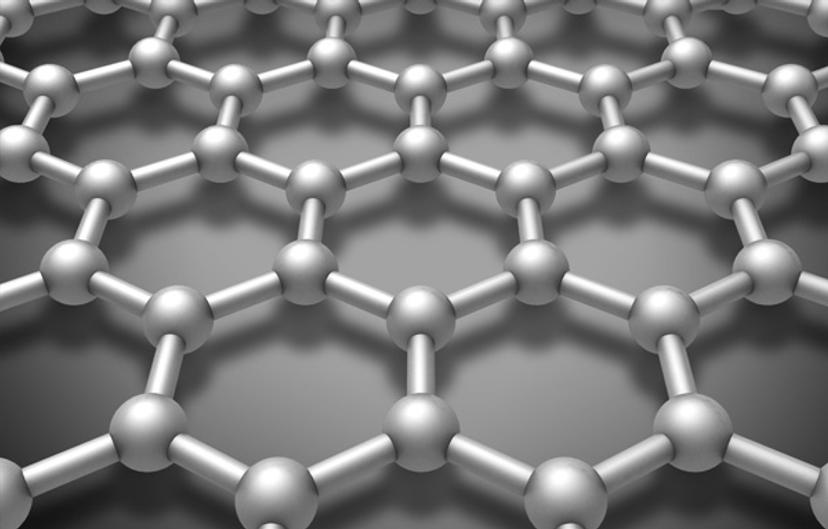

New Graphene Service to Kick-start ‘Miracle Material’ Industry in UK

The collaboration between National Physical Laboratory (NPL) and the National Graphene Institute (NGI) will provide new ways to develop graphene-based technologies

29 Jul 2018A new service has been launched by the National Physical Laboratory (NPL) and the National Graphene Institute (NGI) at the University of Manchester, which will help the UK to cash in on the 'wonder material', graphene, by providing the 'missing link' for industrialization of the material.

Commercially, graphene comes in several forms, such as flakes in a powder or liquid, each with variation in their properties, yield, and reproducibility of the product. Material standardization is crucial to industry uptake but, as with all new technologies, international standards for graphene are in their infancy. As such, manufacturers are unable to verify that the graphene that they are working with has the desired properties. In fact, as it is unregulated, companies cannot even be sure what material they are buying, a point recently highlighted by the FCA in a warning for investors.

Discover the latest innovations in material science, join our Materials Community >>

The new graphene characterization service, led by the organizations leading the standard for graphene, will allow companies to understand the properties of the material they are working with in greater detail. By providing this service, NPL and NGI hope to accelerate the industrialization of graphene in the UK - forging the missing link between graphene research and development, and its application in next generation products.

If the UK fails to put the building blocks in place for industrialization of graphene, it could risk missing out on the associated economic boom.

Hailed as a 'wonder material', graphene is set to improve the quality of life for many across the globe. Its potential applications include inexpensive water purification systems; greener, more efficient cars and planes; flexible phones and solar cells, and even biomedical applications such as wound healing and cancer treatments. Even Internet of Things technologies are set to benefit from wider graphene use as a result of more effective sensors. In fact, the material is so promising that we don't even know all of its applications yet - much like when GPS, a technology that is now indispensable to modern life, was developed.

Graphene was first isolated in the UK by researchers at the University of Manchester, where the NGI is based. Early adopters of graphene technology are already seeing benefits, but in order to fulfil its massive potential, it needs to be industrialized - which will see the quality and reproducibility of the material on offer increase, due to standardization, and the price of graphene drop, due to economies of scale. Only by doing this can we open the door for its wider use and pave the way to the creation of new graphene-inspired applications.

Combining NPL's expertise in test and verification of materials and the NGI's research and development excellence will help to realize this. NPL led the development of the first graphene ISO standard, on graphene terminology, and in collaboration with the NGI, produced the NPL Good Practice Guide on the characterization of graphene. This unrivalled expertise underpins the new characterization service, offering NPL's robust measurements for the properties of commercially-supplied graphene, and comment from the NGI on the material properties and its suitability for selected application(s).

By providing reliable, accurate and consistent measurement and assessment of graphene, and giving industry the information it needs to scale up the production and application of the material, this initiative will help to ensure the UK remains a world-leader in the graphene industry. It will also help to foster graphene innovation hubs across the UK by supporting agile, forward-thinking companies like those seen in Silicon Valley, with a similarly stimulating effect on the economy.

Graham Stuart MP, Minister for Investment, said "Graphene is a revolutionary product that can make internet connections faster, filter salt water and make phone screens unbreakable, and is clearly a prime example of the innovative ability of British companies to change the landscape of manufacturing on a global scale."

"As an international economic department, the Department for International Trade is promoting the very best of British expertise in advanced manufacturing. By making an unprecedented commitment to R&D, we will guarantee that British companies are at the forefront of manufacturing and design for years to come, creating global demand as well as British jobs and prosperity."

Andrew Pollard, Science Area Leader of the Surface Technology Group at NPL, said "Every industry is eagerly awaiting the introduction of graphene technologies, but the lack of standardized measurements has long been a stumbling block for wide industrial implementation."

"Now we can take the next step. Introducing this unique service, alongside the development of international standards, to the UK's emerging graphene economy will accelerate the commercialization of next generation technologies here in the same country the material was first isolated, enabling graphene to go from the lab to the market."

James Baker, CEO of Graphene@Manchester, the University of Manchester said "In order for industry to benefit directly from the opportunities of incorporating graphene into new technologies businesses need to have confidence in the material they are dealing with. This new nationally run service will enable an accurate understanding of graphene which is still just fourteen years young."

"New materials always have a hurdle of quality production, repeatability and functionalization to overcome. The breadth of expertise and understanding at the National Graphene Institute in tandem with the National Physical Laboratory's capability offering accurate material assessment will be critical to accelerate commercialization of products and applications."

Learn more cutting-edge techniques to characterize materials, visit The Scientists’ Channel >>

Ray Gibbs, CEO at Haydale Graphene Industries, said "As Chairman of the Joint Working Group on Graphene Standardization between China and the UK, I am acutely aware of the importance of accurate measurement and characterization of Nano materials."

"This initiative, led by the National Physical Laboratory and The University of Manchester, will help bridge the gap between industry looking to promote its products and the consumers need to be certain of materials and their properties. Confidence is key. Delivery of this will ensure consistent repeatable quality materials are available, essential for commercial uptake."

"In an industry only just reaching delivery of 'commercial' quantities, there is a considerable need for independent verification of material characteristics and properties."

Receive the latest news in material science straight to your inbox, become a member for free today.