Seamless food and beverage testing: There’s an app for that

Discover how Merck’s smartphone-based analytical tool could save time and money in the digital monitoring of food quality and safety

19 Nov 2021

Chemical analysis is essential to quality assurance, regulatory compliance and product development in the food and beverage (F&B) industry. From raw material selection to in-process monitoring and final product testing, analytical methods are used to provide information about the composition of foods for nutritional and dietetic purposes, aid in the standardization of manufacturing processes, and ensure product safety to protect consumers against deleterious, harmful or adulterated food.

For decades, companies have relied heavily on contract laboratory testing services to perform such testing, as conventional methods often require sophisticated sample preparation, long analysis times, and trained personnel to operate instruments. As an alternative, rapid testing methods, such as test strips, offer a simple, efficient and low-cost method for rapid chemical detection in situ. These have become increasingly popular, despite the fact they require manual data analysis and documentation – and now, this is also changing.

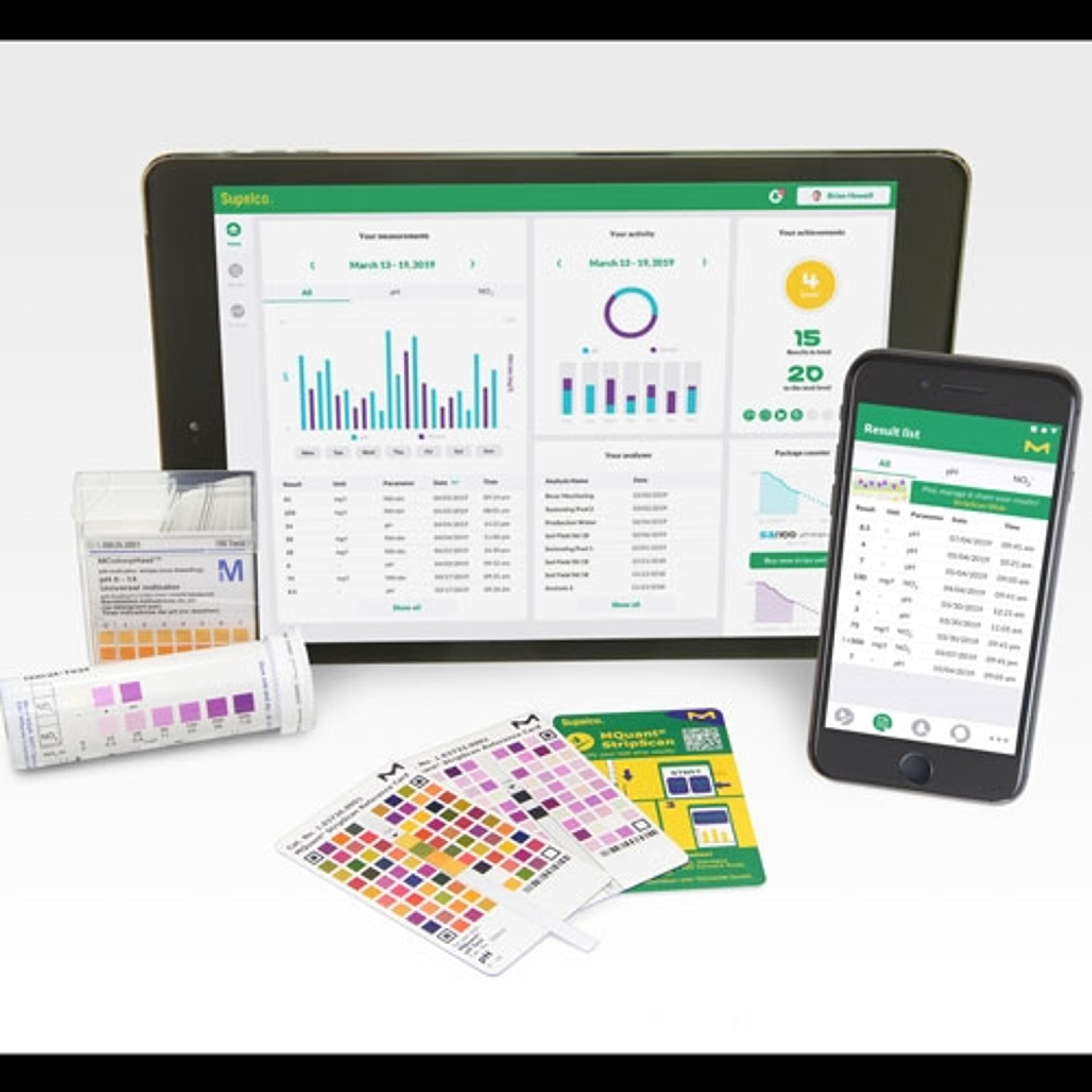

In this interview, we speak with Dr. Saskia Neubacher, global product manager at Merck, about a novel method for measuring two key chemical parameters in foodstuffs, pH and nitrate, that combines test strips with the new smartphone-based MQuant® StripScan app. Neubacher describes how this solution can provide effortless result analysis, management, and visualization, reduce handling times and costs, and simplify regulatory compliance through streamlining digital data transfer.

Why is testing the pH and nitrate content of F&B products important?

SN: pH gives us information as to whether a sample is neutral, acidic, or caustic. In the context of F&B testing, pH is important in many ways. For instance, a very acidic pH in raw fruit can lead to a final product that tastes sour. In food processing, a low pH is often desired as it can prevent contamination. Additionally, if you are using disinfection solutions that are acidic or caustic, then pH testing is a fast way to indicate whether the rinsing of your production system has been fully completed.

Nitrate testing is also important as the consumption of nitrate is considered to have adverse health effects. For nitrate in food and beverages, a maximum contaminant level is set by the FDA and EPA. Food producers need to ensure that they are following these regulations and for this reason, regular testing needs to be performed.

What are some of the challenges of performing these analyses?

SN: For pH testing, electrodes are typically used. These are usually made of glass, meaning they cannot be used in the production environment for safety reasons. The use of pH electrodes can also be quite tedious, as they require a lot of maintenance and repeated calibration. Nitrate can be measured using a variety of techniques, such as chemiluminescence tests, capillary electrophoresis, or spectrofluorometry. All these methods require lab space and a level of training and expertise.

As an alternative, certain rapid test methods such as test strips for pH and nitrate are now available. Here, a strip is dipped in the sample, and after a few seconds, a result is generated. This method is easy, fast and very cost effective. However, the readout is interpreted by human eye by comparing the color that is usually formed on the test strip with those on the color chart. As everybody sees color a bit differently, not to mention there are some people who are color-blind, this makes human error possible. These tests also require users to manually record the documentation by pen and paper, which is often where errors can be made.

With test strips, you have ease of use, speed, and very little training involved, but the subjective readout and lack of reliable documentation is still a challenge. This is where smartphone-based readout tests, for instance, with the MQuant® StripScan app, come in.

How does the StripScan mobile app help overcome these challenges?

SN: With the MQuant® StripScan mobile app, you essentially turn your mobile device into an analytical instrument. You can use the app to read out the test strip with the camera of your mobile device, which then produces instant reliable results that are highly reproducible. As it is the app that produces a readout, this eliminates the possibility of human error. The data that you generate is also stored automatically, so you can always go back and check your data for plausibility. In this way, the app is solving the issue of result reliability and traceable documentation.

How is digital documentation supported on the app?

SN: The MQuant® StripScan app automatically generates a digital result from an otherwise manual or visual readout. All aspects of the acquired data points are documented, including time and date, the image of the strip, test strip batch and sample name, and if the user enables it, also geographical location. This means you have a much richer dataset than if you just document it by pen and paper – plus the data is stored automatically. If you want to transfer your results, you can conveniently use the MQuant® StripScan web interface that is accessible via any web browser. There, you can sort and graph your data and transfer this to your electronic laboratory notebook or your LIMS system.

Who could benefit from this app?

SN: One of our goals is to facilitate better analytical control over production processes in the F&B sector and empower producers to not just rely on contract laboratories. We want to enable smaller F&B producers to be able to perform their own chemical testing to ensure the quality of their products. Another group that would also be interested in this solution is those who may not have access at all to laboratory equipment or the financial opportunities to perform chemical testing. The MQuant® test strips and StripScan mobile app are a big step towards improving accessibility here.

This method could also be used as a pre-test in laboratory environments, be that contract testing or in research, where it can provide a simple, cheap and quick way to determine analyte concentration whilst still maintaining traceability and data documentation.

How do you see smartphone-enabled chemical testing developing in the future?

SN: We are seeing the increasing adoption of smartphone- and tablet-enabled analytical applications in laboratories and manufacturing. Right now, these solutions are becoming more and more popular for use in administrative purposes, for instance, to manage LIMS systems, but also in analytical testing.

The MQuant® StripScan app is a frontrunner in providing novel functionalities that are smartphone-based or tablet-based in an analytical application environment. However, the app is in its infancy, and we are continuously working on expanding its functionality, so that eventually, it can support a vast range of different chemical parameters, spanning water testing, food and beverage testing, and disinfection control. Based on the success that we’ve had with nitrate and pH testing, we’re currently developing new parameters relevant to F&B testing which we hope to have available to users soon.

Do you use Merck products in your lab? Write a review for your chance to win a $400 Amazon gift card >>