Streamlined software enhances PFAS testing efficiency

Discover how waters_connect software solutions are transforming PFAS laboratory operations

3 Jul 2025

Ken Rosnack, Principal Market Development Manager, Waters Corporation, Jonathan Scott, Director Product Management, Waters Corporation, and Scott McCall, Principal Product Owner, Waters Corporation talk to SelectScience about the waters_connect software solutions.

Per- and polyfluoroalkyl substances (PFAS) contamination is causing concern worldwide, putting immense pressure on laboratories to meet the stringent regulatory standards while maintaining high data accuracy alongside high sample volumes and matrix interferences. Explore how waters_connect™ for Quantitation software combined with waters_connect™ System Monitoring software can help scientists address these challenges, enhancing laboratory productivity and ensuring high quality results.

PFAS are a range of synthetic compounds used ubiquitously across industries because of their illustrious qualities ranging from high temperature resistance, to waterproofing. However, compounds in this group are resistant to degradation in the environment due to their immensely strong chain of linked carbon and fluorine atoms. Not only are these compounds bioaccumulative, but they are also reprotoxic and possibly carcinogenic, which is even more concerning when coupled with the fact that they are highly mobile in the environment, leaching from soil to groundwater as well as from soil to plants.

Navigating PFAS analysis challenges

With PFAS being a prominent issue in both consumer and scientific circles, laboratories are seeing an increase in sample volumes for analysis, as well as pressure for faster turnaround times. This increased pressure has presented unique challenges for laboratories in how they resource tasks, analyze samples, review data, and report results quickly and accurately.

Waters™ Corporation has developed a comprehensive analytical workflow solution to help navigate the challenges associated with PFAS analysis. Its waters_connect for Quantitation Software has been developed to ensure users have a highly visual experience, saving time and reducing errors. Users of varying experience levels can produce highly accurate and reliable results with ease by utilizing tools for custom rule sets and regulatory reporting, while meeting the stringent regulatory standards set out by organizations like the U.S. EPA and EFSA.

Alongside pressures on laboratories to conduct PFAS tests at great volumes at the highest standard, scientists are also met with innate challenges when testing PFAS compounds. These challenges include matrix interferences and sample contamination risks. Both of which are successfully combated by the waters_connect for Quantitation Software.

Ensure data integrity and reduce costs

The waters_connect for Quantitation Software works seamlessly with Waters instrumentation in the PFAS testing workflow. Samples start by going through preparation via solid-phase extraction on the Waters Oasis™ WAX cartridge, which is specifically designed for PFAS analysis. To help ensure data integrity and reduce the likelihood of costly reanalysis, each production lot of WAX product is screened for residual PFAS contamination by an independent, accredited laboratory.

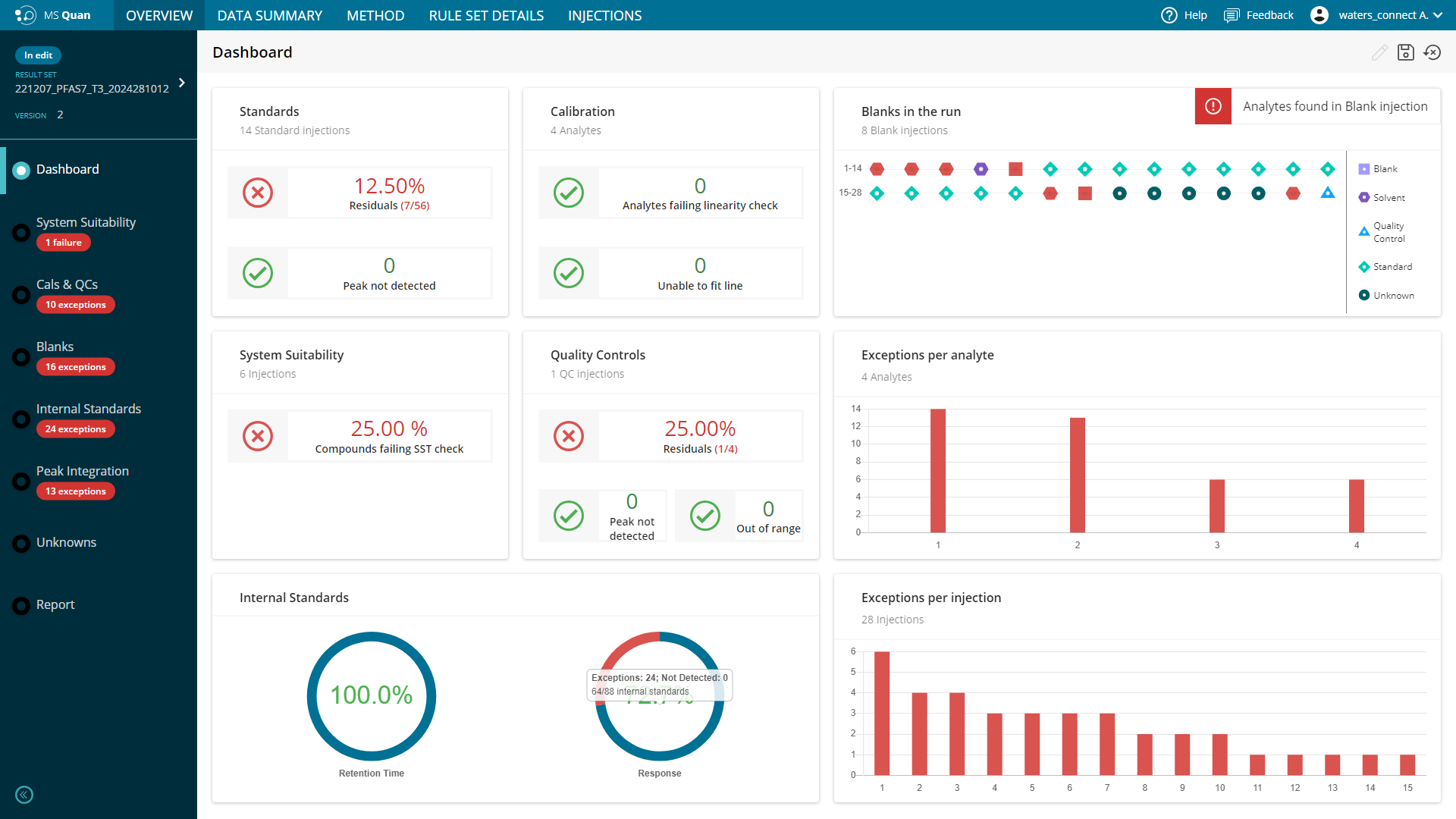

Further analytical testing is then carried out using LC-MS/MS, a gold standard technique for quantitative PFAS determination and regulatory compliance. Data processing follows analytical testing, using waters_connect for Quantitation application, MS Quan. To help meet specific regulatory method requirements (e.g., EPA, EU, ISO), the system can be configured with customizable Rule Sets. These Rule Sets support Exception Focused Review (XFR), enabling analysts to quickly identify and focus on data points that fall outside defined compliance thresholds. Additional features, such as Relative Retention Time checks for EURL regulations and Relative Standard Error calculations for EPA Method 1633, further enhance the robustness of data validation.

Navigating the complex road of PFAS analysis requires more than robust and accurate technology. It demands a partnership beyond the laboratory bench. Together, we are not only responding to the challenges of PFAS but helping others shape a safer and healthier future.

Ken Rosnack Principal Business Market Development Manager, Waters Corporation

Figure 1. Data processing follows analytical testing, using waters_connectTM for Quantitation application, MS Quan.

Optimize operational efficiency

Laboratories that introduce waters_connect for Quantitation Software into their PFAS testing workflows can expect to improve their operational efficiency by reducing the time spent on data processing and review. One such laboratory which has successfully implemented the software is SGS INSTITUT FRESENIUS, Germany. Mr. Stephan Lebartz, Operational Laboratory Manager of Connectivity & Products NonFood, and his team have utilized both Waters instrumentation and software to reduce time spent on data review and processing large sample batches. Benefiting from wrap-around support from Waters, they were able to successfully integrate the software into their workflows and generate high-quality LC-MS/MS data.

Their success can be further explored in the case study, 'Lower Regulatory Limits Prompt Innovation in PFAS Testing’, where Lebartz commented, “software is never perfect, but Waters has been responsive, actively addressing issues, and working collaboratively with us to resolve concerns almost every week. It’s a relief that the software issues are being addressed because, when the software is problematic, it can negatively impact the quality of the data and the efficiency of manual work. We’ve faced challenges with other vendors where the customer service was quite poor. So technical support is a decisive factor when we invest in new software.”

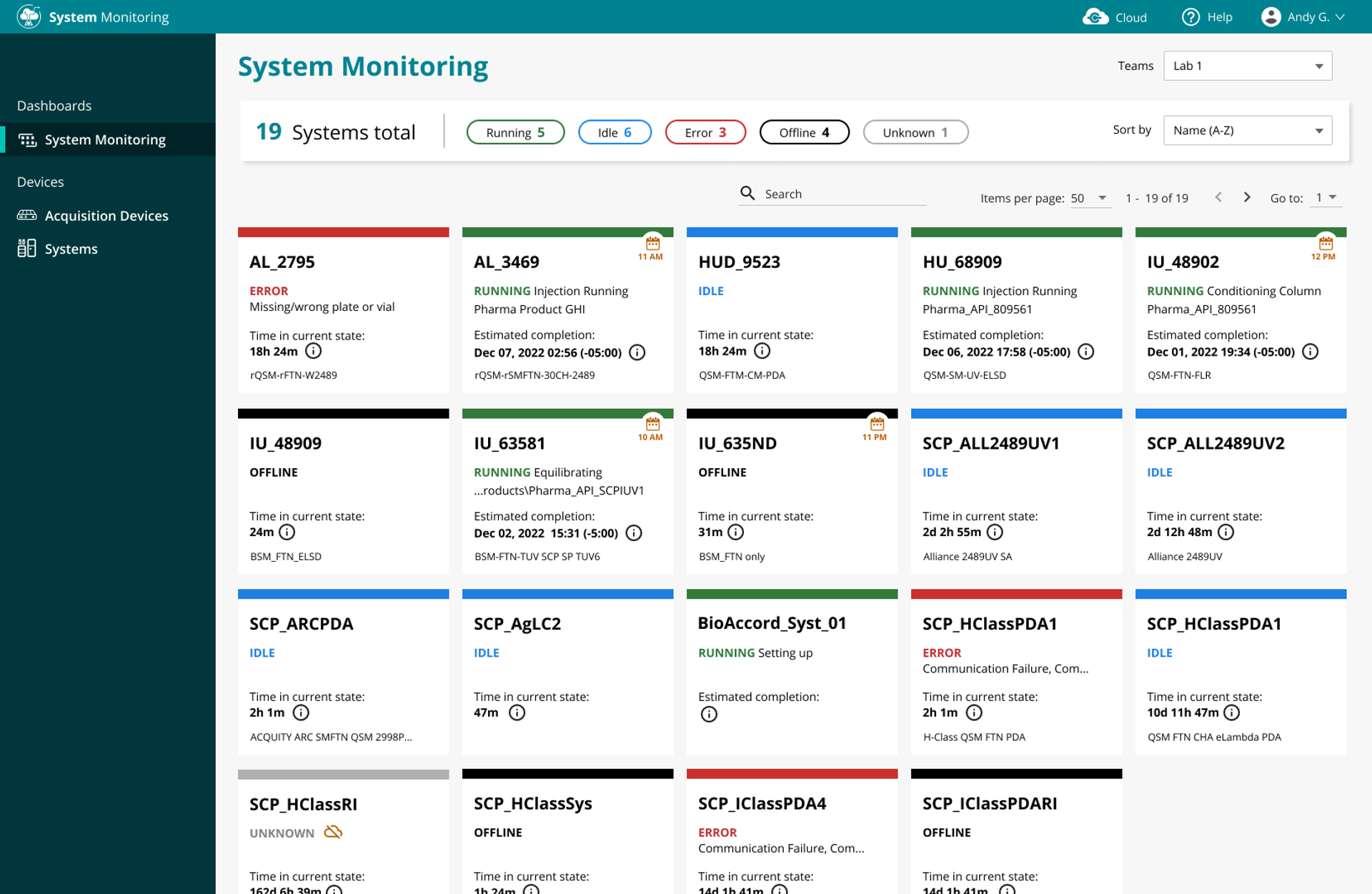

As demands on PFAS labs grow and they strive to achieve even higher throughput, the need to increase efficiency has never been greater. In addition to the efficiency gains in data review and processing enabled by waters_connect for Quantitation, laboratories conducting PFAS testing also benefit from real-time monitoring of their systems. The waters_connect System Monitoring Software takes efficiency even further by providing an at-a-glance view of the status of waters_connect software-controlled systems that can be accessed by the user anytime from anywhere. This at-a-glance view allows PFAS labs to take control of their system usage by easily seeing which systems are currently running, quickly identify systems in error, and find systems that are idle and available for use. Combined with real-time system error notifications, detailed system history, and dynamic system scheduling feature, waters_connect System Monitoring software provides a holistic view of the laboratory that is essential for any busy PFAS laboratory looking to increase their productivity.

Adapting to ever evolving regulatory standards

Figure 2: The waters_connectTM System Monitoring Software takes efficiency even further by providing an at-a-glance view of the status of waters_connect software-controlled systems that can be accessed by the user anytime from anywhere.

Looking to the future, the waters_connect for Quantitation software and waters_connect System Monitoring Software will continue to evolve to meet the changing needs of busy laboratories. As regulatory requirements evolve, waters_connect for Quantitation will keep pace by continuing to provide a compliant-ready solution for labs looking to reduce their quantitative processing and review time. Anticipated enhancements to waters_connect System Monitoring include advanced multi-system history analytics, integration with service request systems, and a full-screen monitoring view for large labs. These enhancements reinforce Waters' focus on laboratory efficiency – improving PFAS testing workflows by making them more efficient, scalable, and capable of handling the expected continued increase in workflows.

The integration of waters_connect Software solutions enables PFAS testing laboratories to increase their laboratory efficiency and streamline their analytical workflow by improving data accuracy, accelerating decision making, and ensuring compliance with ever evolving regulatory standards.