Thermo Fisher Scientific unveils first off-the-shelf validated software solution to automate cell therapy manufacturing workflows

Gibco™ CTS Cellmation™ Software digitally connects instruments from across Thermo Fisher’s cell therapy portfolio to streamline and automate manufacturing

22 Jan 2024

To optimize clinical manufacturing processes for innovators developing breakthrough cell therapies, Thermo Fisher Scientific has announced the launch of the Gibco™ Cell Therapy Systems (CTS™) Cellmation™ Software, an automation solution designed to connect and integrate workflows across multiple Thermo Fisher Scientific cell therapy instruments while enabling cGMP compliance. This new offering may help eliminate the need for costly custom software projects and extensive validation, saving valuable time and resources during the cell therapy manufacturing process and helping to deliver curative therapies more quickly and safely to patients.

The cell therapy manufacturing process is estimated to include upwards of 40 manual touchpoints, increasing opportunities for errors and contamination that can lead to failure and delay potentially life-saving treatment for those who need it most. The CTS Cellmation Software, powered by Emerson’s DeltaV™ Distributed Control System (DCS), connects Thermo Fisher’s cell therapy instruments within a single, user-friendly interface, reducing the number of manual touchpoints required. By establishing an automated workflow across multiple stages of cell therapy manufacturing, CTS Cellmation Software helps enable traceability, repeatability and 21 CFR Part 11 compliance with secured data connectivity.

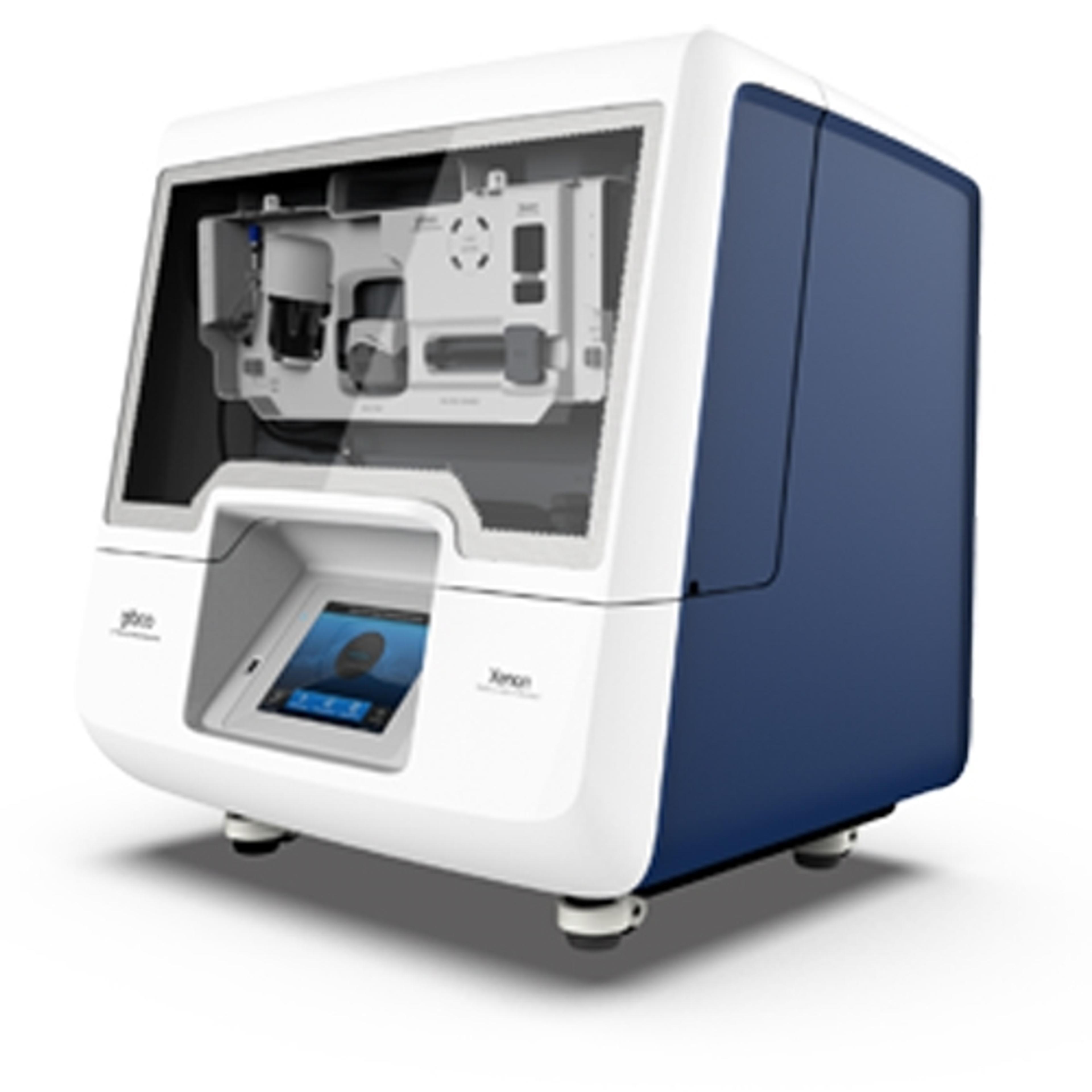

At present, CTS Cellmation Software connects core Thermo Fisher Scientific cell therapy instruments, including solutions from the Gibco CTS portfolio. These instruments, along with their supporting consumables and software products enable GMP-compliant, closed system manufacturing.