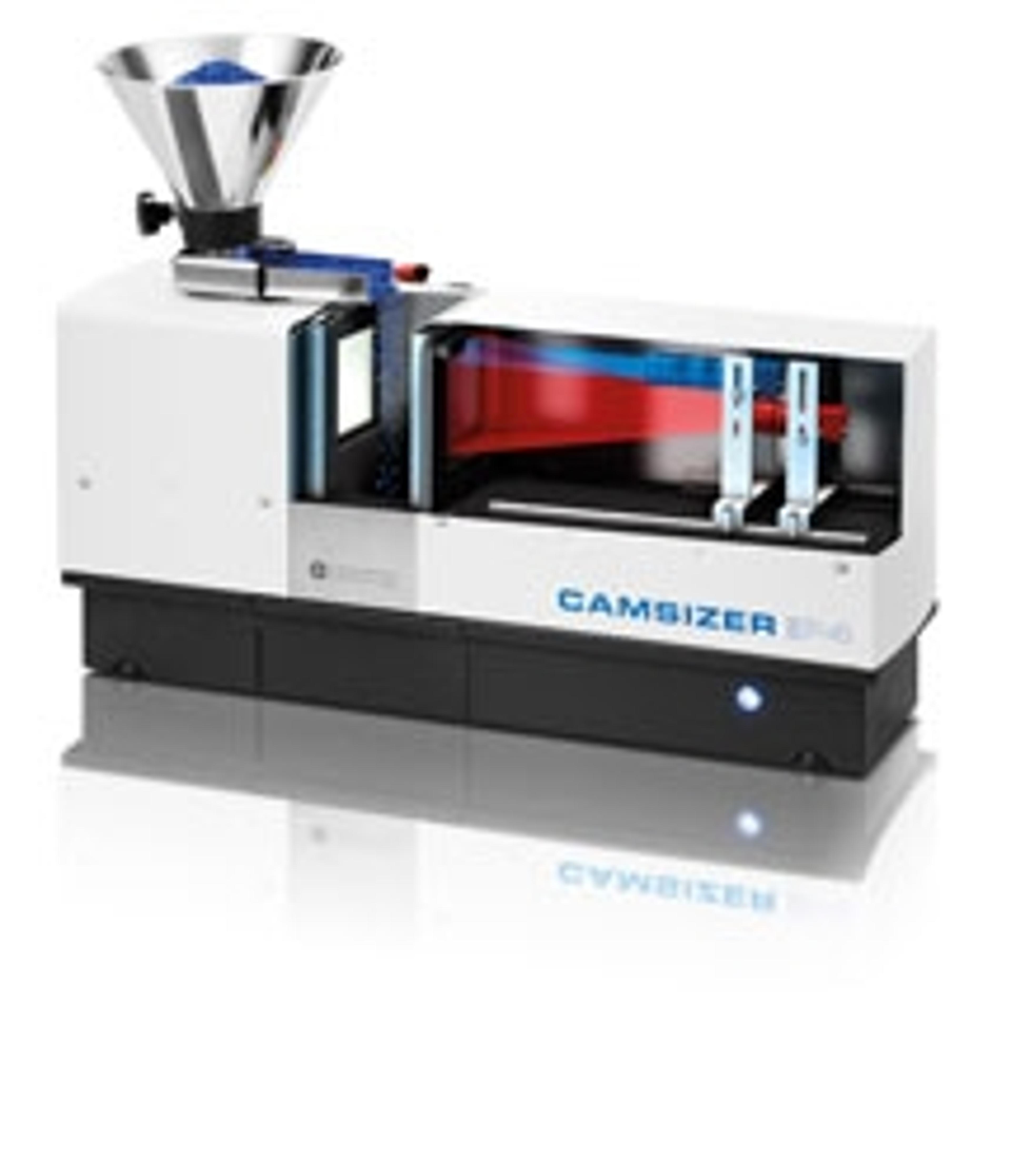

CAMSIZER X2 - Optical Particle Analyzer for Fine Powders

With Unique Dual Camera Technology

Perfect for Quality Assurance

Metal additive manufacturing

Regularly used to characterise and monitor powder during recycling in LPBF. Ease of use and low sample quantity allows results on PSD and morphology to be seen in minutes for quality assurance.

Review Date: 12 Dec 2022 | Microtrac

We only use the X-Fall more since our materials are big to measure other ways.

Materials (chemicals) characterization

We have the three modules, X-Fall, X-Flow and X-Jet. We only use the first two and sometimes it challenging to get reproducible results. We only use the X-Fall more since the materials are so big to measure other ways. Most of the time static is our greatest enemy. Materials get very staticy and get all over the place using the X-Fall.

Review Date: 7 Dec 2022 | Microtrac

We rely heavily on the results from these analyzers! Accurate and repeatable!

small particle size distribution

The product is very easy to use; we get a lot more information from this system than we did from our previous analyzer. The staff diligently works with developing and meeting our internal needs and has been more than willing to provide the education and background necessary to get the biggest bang for our buck! We are very pleased with this instrument.

Review Date: 7 Dec 2022 | Microtrac

It's a must have instrument for analytical lab

Small molecule active pharmaceutical ingredients for various therapeutic conditions and indications

Been using this instrument for a while now for particle size analysis of our small molecule APIs. The performance, accuracy & reproducibility is excellent. The amazing part is its ability to work with very small sample size. Very happy with the instrument.

Review Date: 11 Dec 2021 | Microtrac

The CAMSIZER X2 uses Dynamic Image Analysis to improve quality control of fine powders in a size range from 0.8 µm to 8 mm. The instrument provides precise and fast analysis of particle size and particle shape which helps to improve product quality, reduce rejects and save costs.

Correct sample preparation and dispersion of the particles before they pass the measurement field are as important as the actual analysis. Particularly for fine powders which tend to agglomerate, sufficient dispersion is crucial to the reliability of the measurement results. Therefore, various modes of sample feeding help to achieve separation of the agglomerates without destroying individual particles.

The modular X-Change System fulfils this requirement in a perfect way. With fine, agglomerating samples it is difficult to record the properties of a single particle. Therefore, it is important to have various possibilities of feeding the sample to the analysis area to be able to find for each material the optimum between the desired dispersion of the agglomerates and the undesired destruction of the individual particle. The CAMSIZER X2 offers three alternative dispersion methods: by gravity, by air pressure and in liquids. Thus, it is possible to choose the optimum method for each sample type.