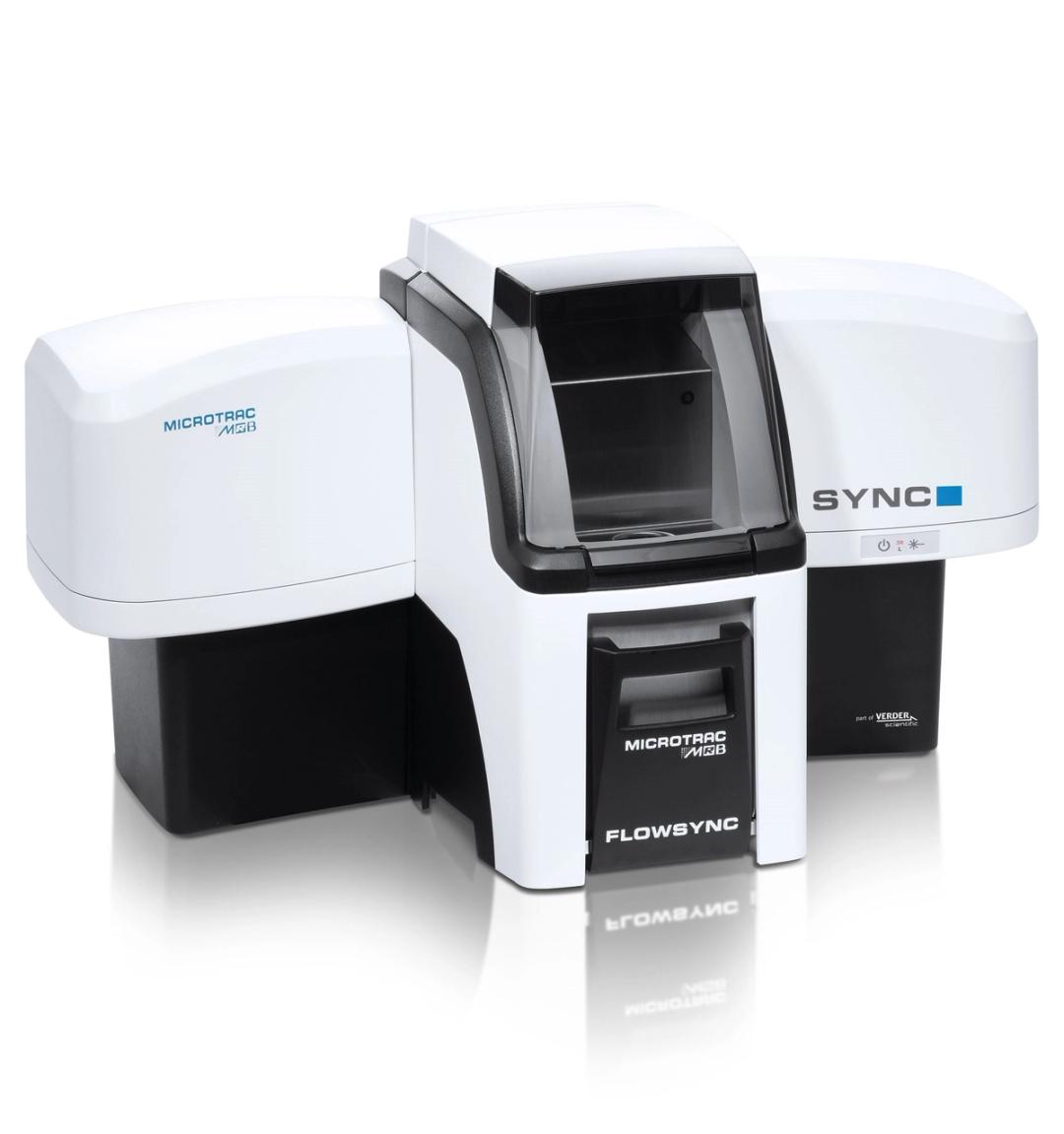

Particle Size and Shape Analyzer SYNC

The best of both worlds - laser diffraction and image analysis combined

Great results, can't meet customers requirements without the unit.

Particle size analysis of boron nitride ceramic powders

I have used Microtrac instruments for over 35 years and the dependability has been excellent. If you have a problem (and it did happen once) the service department is excellent and will work with you to help solve the problem. The instruments are easy to use and they present repeatable results. In my opinion, the name Microtrac is so widely used that it is often used in place of the term Particle Size Analysis.

Review Date: 7 Dec 2022 | Microtrac

Fundamental piece of equipment to have in the lab!

Powder Metallurgy

There was a little bit of a learning curve in terms of making sure that the powder was correctly suspended in the wet system to mitigate the possibility of air bubbles but the application team swiftly addressed the issues we were having. It runs beautifully.

Review Date: 7 Dec 2022 | Microtrac

Easy to use and very reproduceable results

Fumed Silica

Easy to use and very reproduceable results

Review Date: 6 Dec 2022 | Microtrac

High CP value

Evaluate the stability of Coating dispersion

It is easily to use and high sensitivity.

Review Date: 6 Dec 2022 | Microtrac

This instrument has been critical for the understanding of many of our materials.

powder characterization

The Microtrac Sync instrument is a very reliable means of generating size and shape data for a variety of particles that we study. I have been impressed with the ease of use and the support that is provided by Microtrac.

Review Date: 6 Dec 2022 | Microtrac

Very easy to analyse

Rock samples

Very easy to apply and the results are accurate

Review Date: 17 Aug 2022 | Microtrac

Impressive results and analysis options. Short measurement runtime.

dry powder morphological measurements, shape parameters analysis

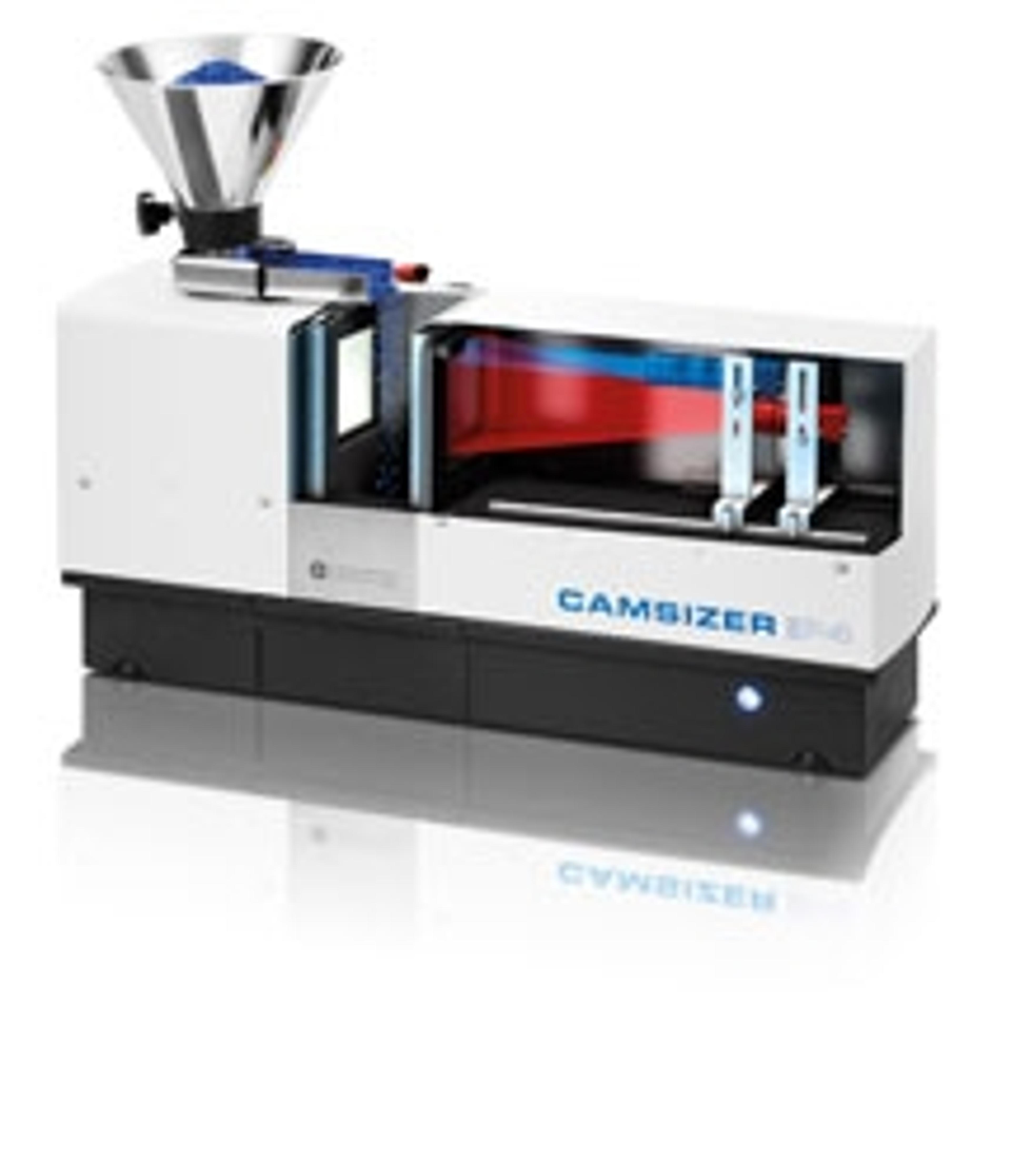

Overall a very effective instrument for dry powders (we use a dry sample module). A hybrid analyzer (laser diffraction and dynamic imaging analysis) gives great morphological results at low particle accelerators (at high accelerations image cameras lack of speed to capture particles). Very powerful software-wide options - correlation options among morphological parameters, impressive scatter diagrams. Reproducible results can be achieved. Moderate easy of use - some knowledge, training should be. After-sales care / remote service may take longer than expected. Many configurations of instruments are available (for fine or coarse samples - different camera lenses and lasers (up to three); dry and wet sampling also available). The value of money is acceptable, but the camera should be faster to capture accelerated particles, also software "Size and Shape Data" at results - reports should be more easily changeable (add/remove data without any rerun).

Review Date: 9 Dec 2021 | Microtrac

Fast, accurate and easy to use analyzer

Ceramics and refractories materials

Really easy to use. Fast and accurate results on many different samples liquid or solid. Some problems with the system in the beginning but the service team got us cover real quick. We like the possibility it offers us for multiple developments projects.

Review Date: 9 Dec 2021 | Microtrac

Great result

Soil samples

It was easy and good.

Review Date: 9 Dec 2021 | Microtrac

The Microtrac MRB SYNC Analyzer provides traditional users of laser diffraction technology with exciting new capabilities to characterize their materials. The proven tri-laser technology provides accurate and repeatable laser diffraction information from light detected over 163 degrees of angular scatter. When combined with state-of-the-art camera technology capturing images of the particle stream at the same time, the SYNC offers not only size data but also additional information about the shape of the materials and the quality of the dispersion.

The patented synchronous measurement technology of the SYNC allows users to make both a laser diffraction measurement and image analysis on a single sample, in the same sample cell at the same time: One sample, one optical bench, one flow path, one sample cell, one integrated GUI, one analysis.

This makes the SYNC ideally suited for both routine QC and research applications; it provides valuable information to researchers as they develop new materials and processes. The powerful software interface offers both particle size distribution information as well as a multitude of morphological parameters. The patented BLEND routine allows users to examine materials over a wide size range from 0.01 microns to 4000 microns