Eppendorf BioFlo® 320

The BioFlo 320 seamlessly blends beauty and utility in one all-inclusive package. A new industrial design, flexibility between interchangeable autoclavable and single-use vessels, intelligent sensors, Ethernet connectivity, and a new software package are only a few of the features that set it apart from the competition

The best product of my lab!

Fermentation

The product is fantastic to my fermentations and make the difference in the publications of my lab.

Review Date: 30 Nov 2021 | Eppendorf

Great results!!! A good option for researchers around the world!!!

Production of enzymes and secondary metabolites from microorganisms

Bioflo 320 meets with excellence my demand for the production of enzymes and other metabolites of interest from microorganisms. Its use is easy to handle, in addition to having an excellent after-sales consultancy and money value.

Review Date: 20 Sept 2021 | Eppendorf

The BioFlo 320 seamlessly blends beauty and utility in one all-inclusive package. A new industrial design, flexibility between interchangeable autoclavable and single-use vessels, intelligent sensors, Ethernet connectivity, and a new software package are only a few of the features that set it apart from the competition.

Extensive options give you the customizable solution your lab requires. Combined with the strict quality standards that all Eppendorf products are held to, the BioFlo 320 truly is the new premium choice in benchtop bioprocess systems.

Features:

- Interchangeable autoclavable and BioBLU® single-use vessels

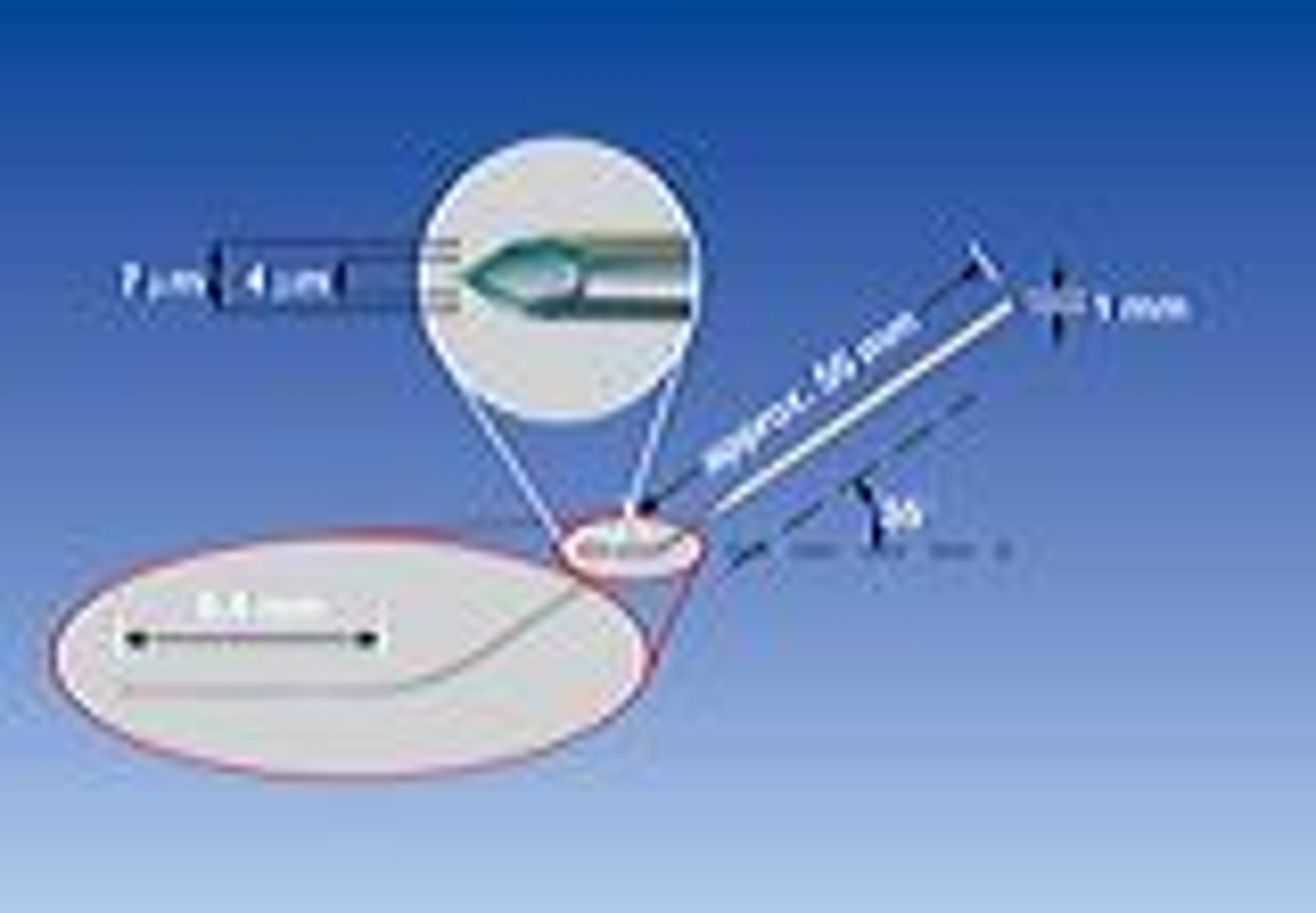

- Integrated Mettler Toledo Intelligent Sensor Management (ISM) platform

- Control up to eight (8) systems from a single-user interface

- Universal control for both microbial and cell culture applications

- Field-upgradable TMFC drawers for sparge and overlay gas

- Enhanced software package with new cascade and time profile features

- Built-in optical pH sensing technology for use with the BioBLU® single-use vessels

- Ethernet communication for multi-unit control, Eppendorf SCADA software, and IP addressing

- Up to six (6) integrated pumps capable of operating in variable speed mode

- Eight (8) independently controlled process gas supplies

Applications:

- Research and Development in cell culture and microbiology

- Laboratory and pilot scale fermentation of aerobic and anaerobic bacteria, yeasts and fungi

- Cultivation of mammalian, insect, and human cell lines

- Specialized applications such as stem cell culture or biofuel/biopolymer development

- Specialized packed-bed impeller for vaccine production in anchorage and non-anchorage dependent cell lines

- Suitable for batch, fed batch, and continuous processes

- Validation packages available for GMP regulated processes