Eppendorf DASGIP® Parallel Bioreactor System

DASGIP Parallel Bioreactor Systems for R&D and process development in both cell culture and microbiology allow for advanced bioprocess control and automation. Parallel processing, precise control of all relevant parameters, user-defined profiles and innumerable automation features result in accelerated and highly efficient process development. Our DASware software solutions support DoE, process historians and comprehensive…

A good in-parellel fermentation system.

Fermentation

The user interface is very to learn and use, unlike other systems that require writing scripts. It is cost effective compared to similar products from other vendors. However, the after sale service could be hit or miss.

Review Date: 15 Nov 2021 | Eppendorf

Optimization Of Bacterial Growth

I have used Eppendorf DASGIP® Parallel Bioreactor System for process development with bacteria growth with various carbon and nitrogen source. The system will fit what an experiment requires and can monitor most of the parameters. The only thing is for people who just use one or a few times, the software requires you to study for a long time and or you will need training.

Review Date: 17 Jun 2014 | Eppendorf

Manufacturer's Response

“Thank you for reviewing our product. We value your opinion.<br><br> Eppendorf DASGIP Parallel Bioreactor Systems are delivered ready-to-use with complete installation and user training at the customer’s site to ensure the highest productivity right from the start. Since we are aware that knowledge transfer is a critical issue we also offer individual trainings besides the initial training – for example training of new employees. Also users that already have experience with Eppendorf cultivation systems will find it useful to review their knowledge. During these trainings we address both technical aspects of the system as well as your specific applications while both the hardware and software are explained in detail. All trainings are performed at the customer’s site to have the training focused on their specific application.The structure and methods of the training can be chosen according to your requirements from general overview to detailed sessions on specific products or issues. Training in small groups is as possible as well as one on one training.<br><br> A service specialist will be in touch to discuss and see if additional training is useful.”

DASGIP Parallel Bioreactor Systems for R&D and process development in both cell culture and microbiology allow for advanced bioprocess control and automation.

Parallel processing, precise control of all relevant parameters, user-defined profiles and innumerable automation features result in accelerated and highly efficient process development. Our DASware software solutions support DoE, process historians and comprehensive data management.

Configurable solutions address the unique requirements of microbial, phototrophic, mammalian and human cells, stem cell applications, as well as biofuel and biopolymer processes.

Eppendorf DASGIP® Parallel Bioreactor System Features:

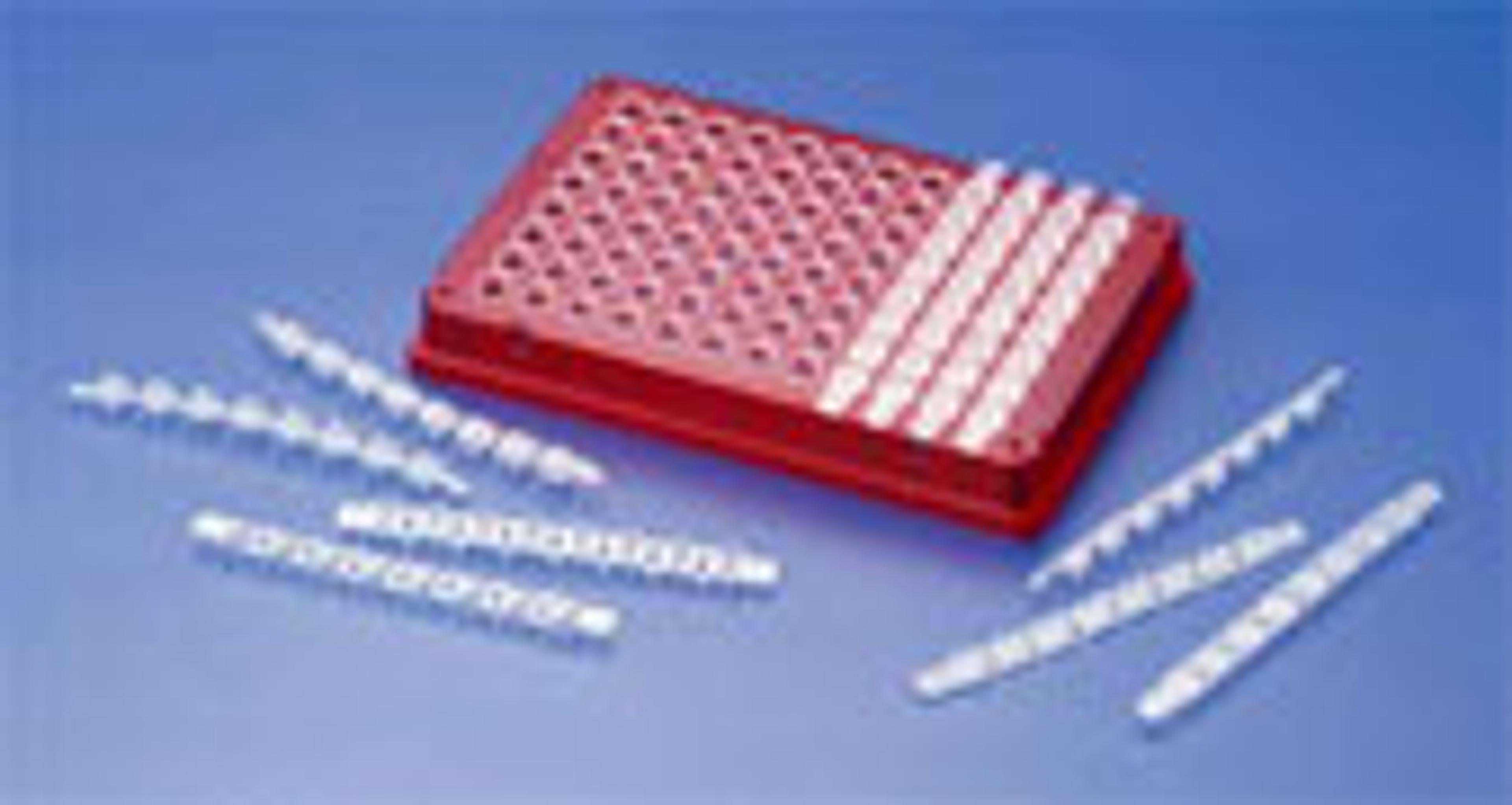

- Advanced process control and parallel operation of up to 16 glass or single-use bioreactors;

- DASGIP Bioblock for advanced and user-friendly temperature control;

- Modular design of control units allows for flexible system configurations that meet the demands of specific applications;

- Control of agitation, pH, level and DO (including customizable cascade modes) in each bioreactor;

- Variable speed pumps for accurate liquid addition and operation in batch, fed-batch, continuous and cyclic perfusion mode;

- Optical absorbance measurement for online calculation of e.g. OD600 or cell dry weight;

- TMFC individual gas mixing of air, N2, O2 and CO2;

- Online calculation of OTR, CTR and RQ;

- DASware control Software for advanced process control;

- Compatible with DASware Software Suite for interconnectivity and bioprocess information management.

Applications:

- Research and development in cell culture and microbiology as well as phototrophic applications;

- Lab scale fermentation of aerobe and anaerobe bacteria, yeasts and fungi;

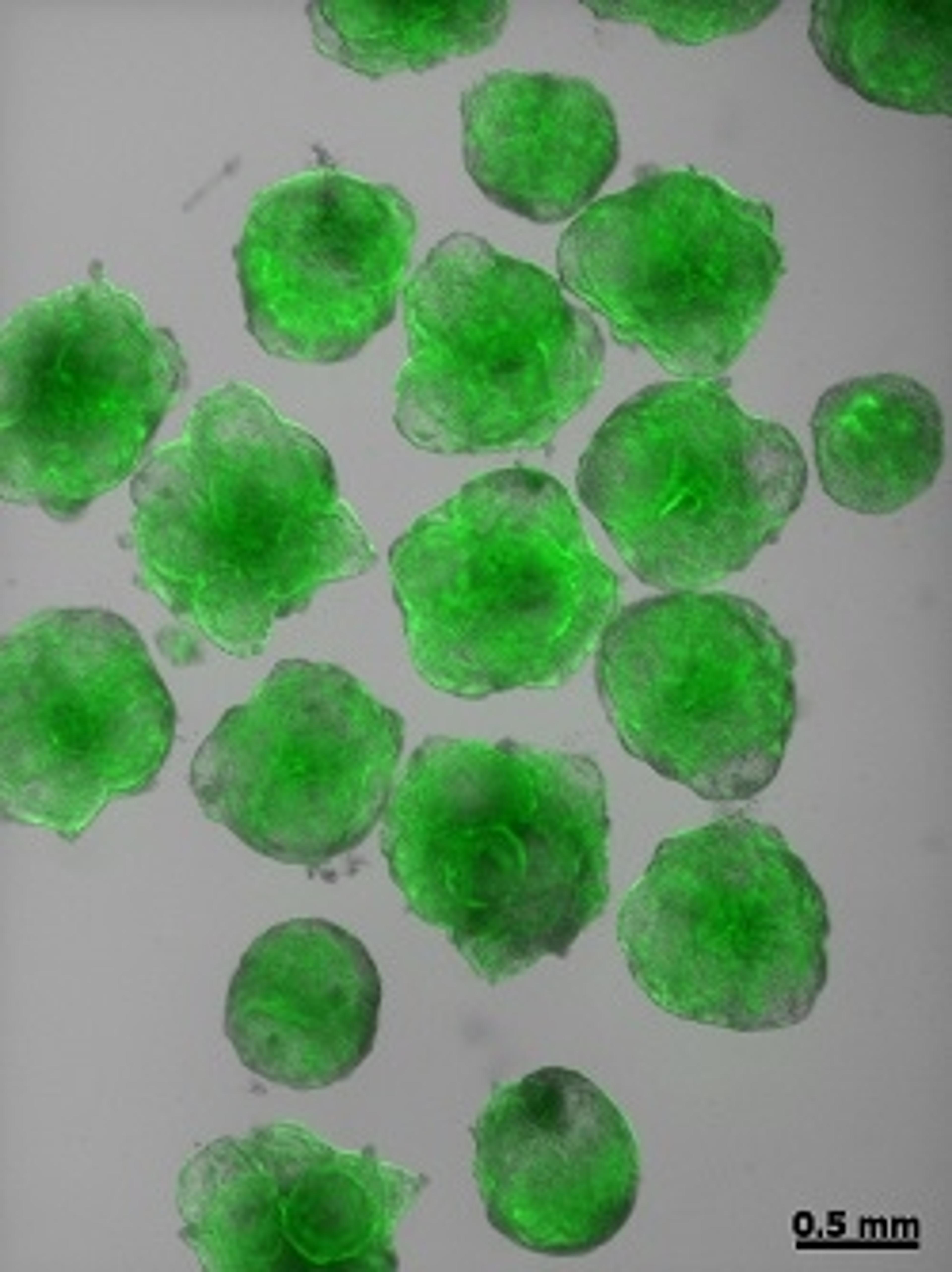

- Cultivation of mammalian, insect and human cell lines;

- Special applications such as stem cell culture or biofuel/biopolymer development.