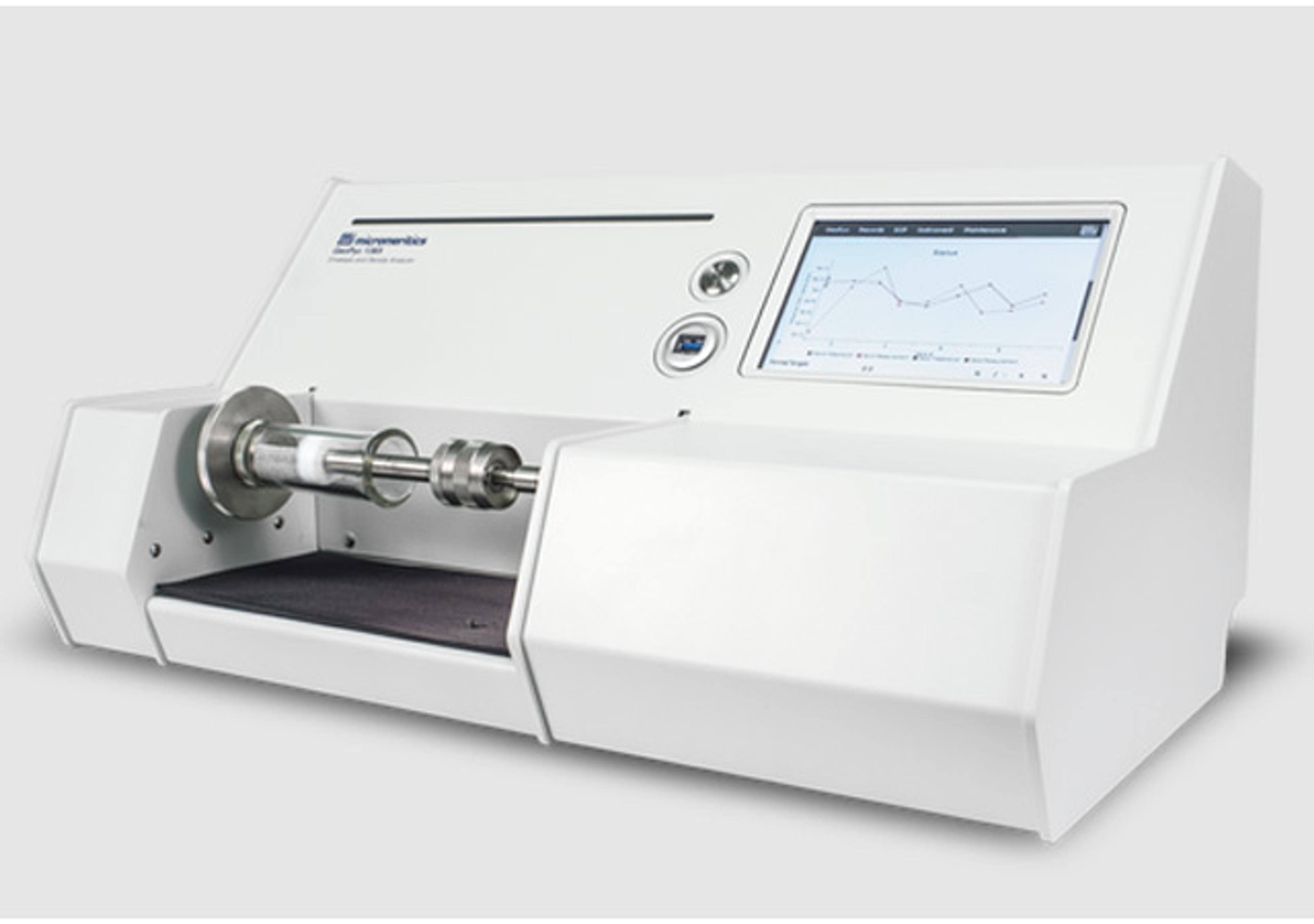

Facility Monitoring System

Beckman Coulter Life Sciences provide scalable Facility Monitoring Systems (FMS) that can be configured to meet a wide spectrum of cleanroom management needs for various industries—including pharmaceutical production.

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Beckman Coulter Life Sciences provide scalable Facility Monitoring Systems (FMS) that can be configured to meet a wide spectrum of cleanroom management needs for various industries—including pharmaceutical production. Among parameters that can be efficiently and reliably monitored using a Beckman Coulter FMS are non-viable/viable air sampling, differential pressure, air temperature and relative humidity. All of the company’s FMS solutions are based on an open-architecture platform designed to enable easy, streamlined integration with existing customer systems (SCADA). Each instrument is built around proven MET ONE technology, including the portable MET ONE 3400 series for routine monitoring and cleanroom classification, as well as the 6000 and 7000 series of fixed, non-viable air particle counters. MET ONE software platforms feature intuitive interfaces to help make them easy to use, thereby reducing the potential for human error that can occur with manual SOP monitoring. To avoid losses from product contamination, stack lights, audible alarms and process shutdown signals from a Beckman Coulter FMS can prompt an immediate production line response whenever an excursion happens. In addition, to help centralize reporting and simplify EUGMP/FDA compliance (e.g., for ISO 14644 and 21 CFR Part 11), Beckman FMS data can be integrated into a single-release, electronically signed paperless report.

- Workflow-optimized, integrated solutions to monitor your cleanroom

- 21 CFR Part 11 enabling software workflow to ensure secure data management

- Integrate portables and remote air particle counters

- Industry standard interfaces (OPC, ODBC) for integration with other systems

- Support for 32 location manifold integration for automated routine environmental monitoring