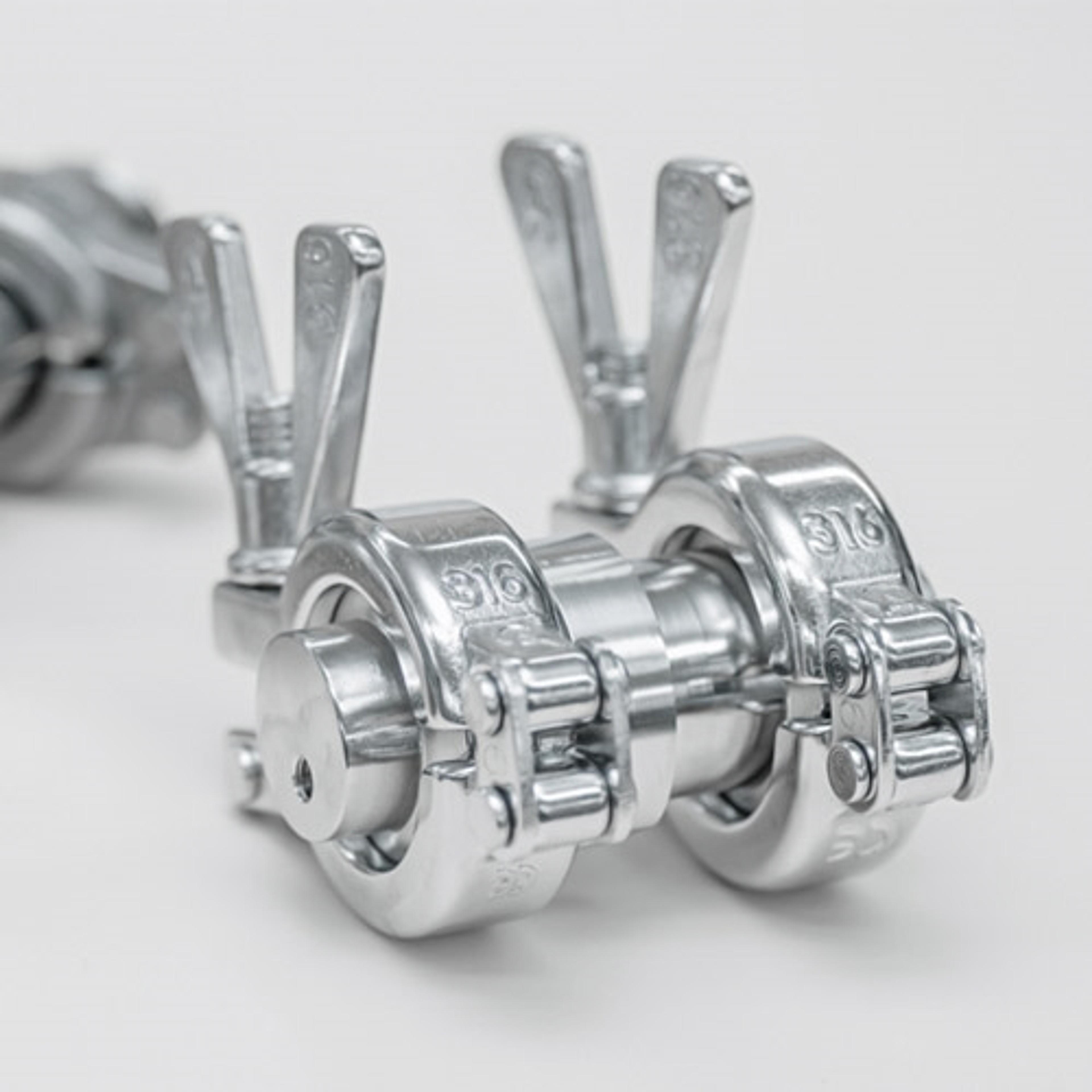

Micropore AXF-mini advanced crossflow micro mixer

Advanced crossflow (AXF) mixing has solved the problem of how to efficiently create the highest quality micro and nano-spheres, emulsions, and crystals around a chosen size with a robust, cost-effective, scalable technology.

The AXF-Mini is Micropore’s smallest Advanced Crossflow (AXF) mixer. Designed for small scale work. It is the starting point on a product development journey, enabling discovery, preclinical and clinical work on wide range of particles sizes and different applications. It has no moving parts; features no single-use components; and can be used to produce volumes as low as the 1-2mLs needed during discovery. But throughput can then be turned up to produce the 10-20mLs needed for pre-clinical; and the 100-200mLs needed for clinical studies.

- Disperse phase hold-up volume - 0.1mL

- Continuous phase hold-up volume - 0.3mL

- Minimum disperse phase aliquot - 0.2mL

- Volume to achieve steady state operation - 0.2mL

Key features

- Narrow particle size distribution (typical CV~10%)

- Significant reduction in waste

- Preservation of biological activity of biomolecules after encapsulation

- Up to 30% lower energy usage compared to other mixing technologies

- Continuous process, & low-cost operation with reliable process design.

More cost-efficient micro mixing

Micropore’s AXF technology delivers particle size control in a gentle, low-shear process that preserves sensitive actives, like RNA, while keeping the narrow, controlled size distributions & PDI’s as you scale up. Combined with its minimal hold up volumes, AXF devices offer significant cost efficiency over alternative technologies by minimising the waste of expensive ingredients.

Application notes

The AXF-mini scales up seamlessly to Micropore’s AXF-1 & AXF-n units capable of up to up to 1,500L/hr throughputs. The whole AXF range use same conditions, mechanisms, and geometry, irrespective of scale. Whether you are making LNP vaccines, PLGA encapsulated API’s, emulsions, crystals, or other products, the AXF-Mini was created for lab bench discovery.