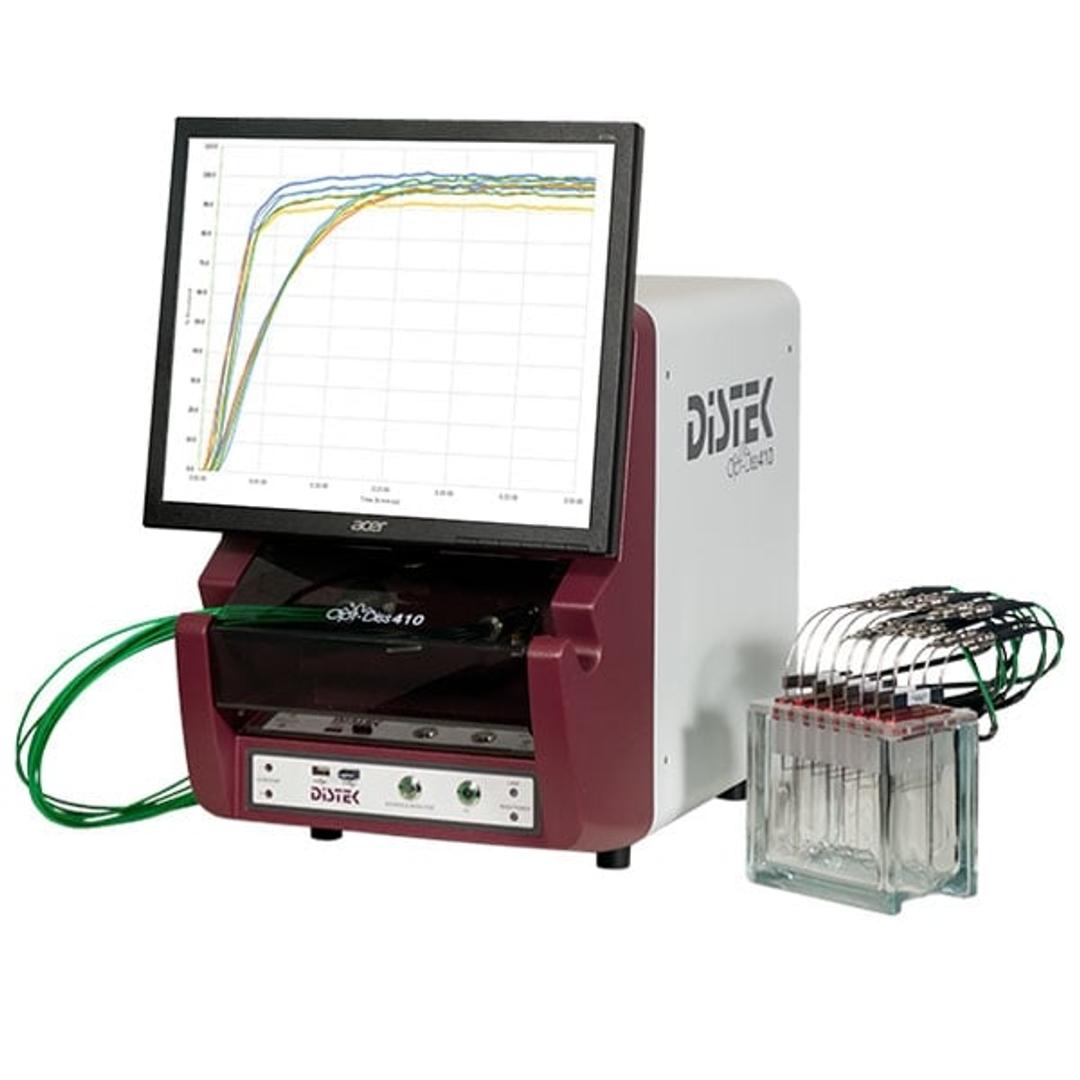

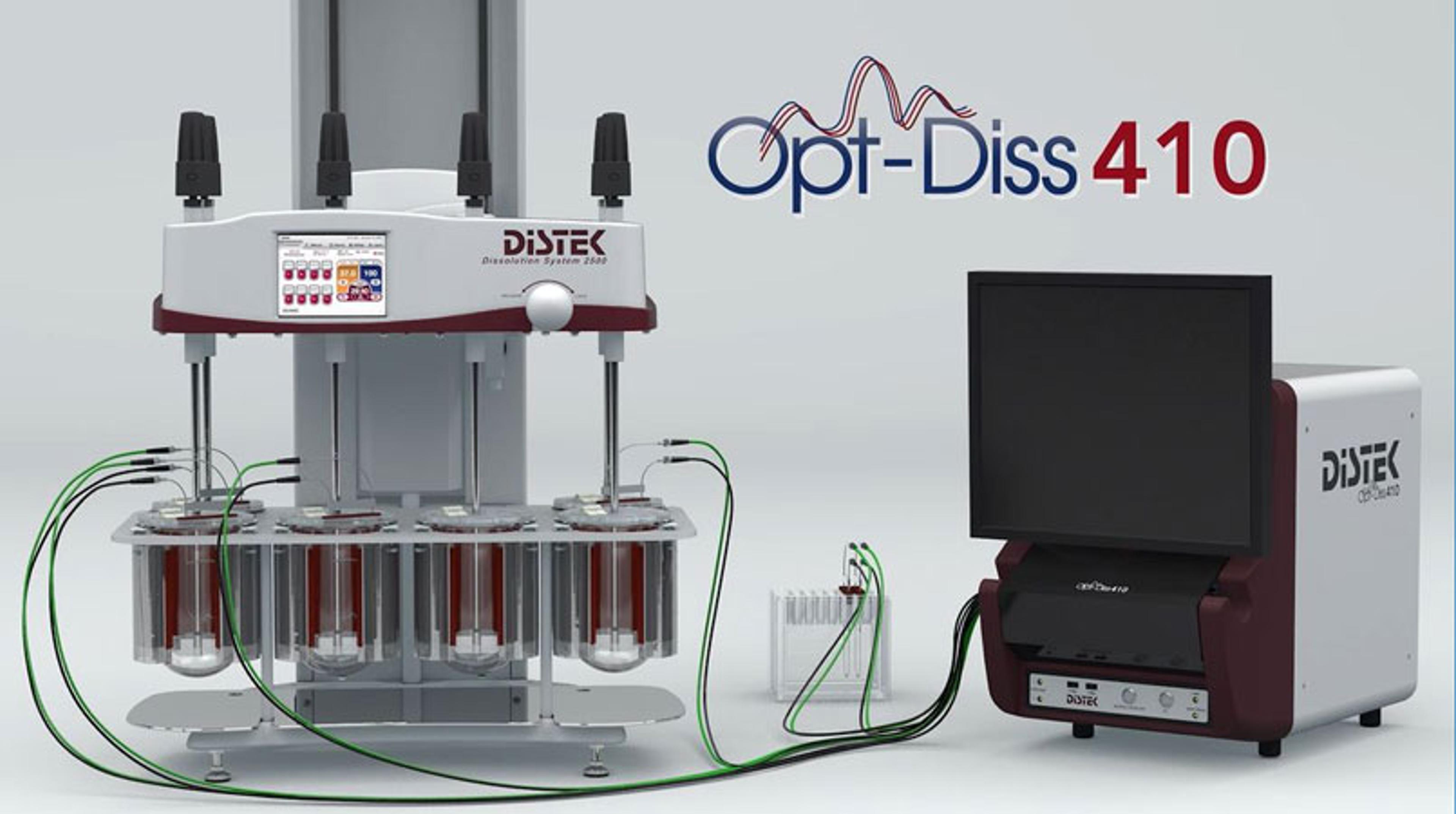

Opt-Diss 410 UV Fiber Optic Dissolution

No more sampling! The Distek Opt-Diss 410 in-situ fiber optic UV system measures directly in the vessel, eliminating the need for conventional sampling, and with-it consumables like filters, tubing, and syringes, saving time, labor, and money. Moving light rather than liquids also allows generating near real-time dissolution data and nearly limitless sample points as frequently as every five seconds.

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Opt-Diss is a great investment for formulation labs!

Pharmaceutical development, preformulation, formulation, dissolution kinetics, supersaturation testi

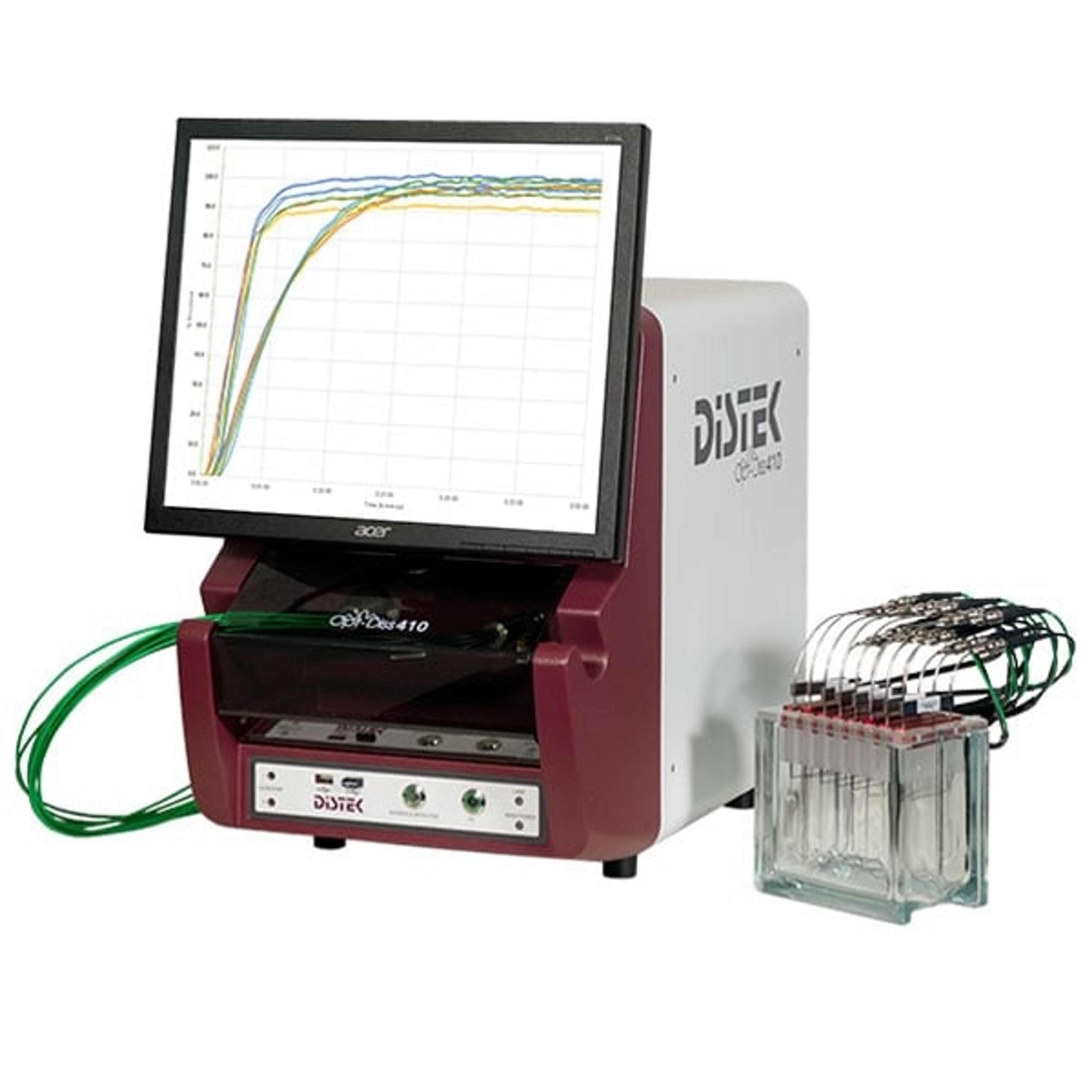

I started using Distek's Opt-Diss fiber optics technology more than 10 years ago in a different company and am a big fan of it. The old unit lasted quite a while. We purchased Opt-Diss 410 a couple of years ago and have been very happy with it. The ease of use and instant data availability is a big factor for us in a development setting. There is real time data, no volume correction, no line purging, no air bubble problem. The new model is more compact than the first generation and starting up sequence is much simpler. One of the biggest advantages is that you can take very frequent data points at the start of dissolution and program the sampling according to the characteristics of the formulation. Cleaning is very easy after use. The probes are surprisingly robust. Even after I bought the new Opt-Diss 410, I kept using the old fiber bundle and probes I bought 12 years ago and they are working nicely. I enjoyed working with all the sales managers I interacted with. The field support staff have been excellent, very dedicated and very friendly. I applaud Distek's retention of good people! It makes a huge difference in the user experience!

Review Date: 14 Nov 2019 | Distek, Inc.

No more sampling! The Distek Opt-Diss 410 in-situ fiber optic UV system measures directly in the vessel, eliminating the need for conventional sampling, and with-it consumables like filters, tubing, and syringes, saving time, labor, and money. Moving light rather than liquids also allows for generating near real-time dissolution data and nearly limitless sample points as frequently as every five seconds.

SIMPLE & EFFICIENT DISSOLUTION TESTING

Truly automated data collection and analysis mean the start of the test to a complete report only takes as long as the test itself, with no operator interaction required. And collecting data as fast as every 5 seconds is no more effort.

MULTICOMPONENT ANALYSIS

Measure two components in the same dissolution test without the need for LC, including products with two APIs or interaction with excipients, coatings, capsules, or any other source of deviation of the UV spectra.

RAPID AND ROUTINE DATA COLLECTION

With acquisition speeds as fast as 5 seconds for all vessels, collecting near real-time dissolution profiles is ideal for formulators to understand complicated release dynamics as it occurs.

IN-SITU UV MEASUREMENTS

Keeping the science in the vessel! The Opt-Diss 410 measures directly in the vessel, eliminating manual or automated sampling along with the associated consumables, labor, and off-line analysis.

- Choose from patented ARCH probes designed specifically for dissolution testing with negligible hydrodynamic effect

- Or conventional dip probes with fixed or interchangeable pathlengths

SINGLE SOFTWARE PACKAGE

21 CFR Part 11 compliant, the Opt-Diss 410 is the only fully integrated UV fiber optic dissolution solution with a single software package controlling the entire system.

INDUSTRY APPROVED

Top pharmaceutical companies as well as the FDA and USP have adopted the Opt-Diss by Distek.