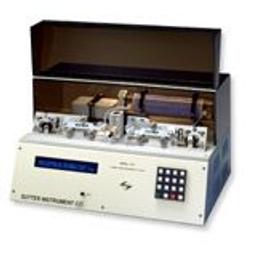

P-97 Flaming/Brown Micropipette Puller

The Model P-97 micropipette puller is the latest generation of the Flaming/Brown type puller for fabrication of micropipettes, patch pipettes and microinjection needles. While retaining many of the features on the Model P-87, the P-97 offers improvements in mechanical, electronic and software design. The result is better control of the pulling process and a higher degree of reproducibility. Features: Environmental chamber…

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

The best pipette puller available in the market for already many years.

Recording of Ion Channel Functional Activity

The best pipette puller available in the market for already many years. Reliable and reproducible fabrication of micro pipettes for cell membrane ion channel activity recording. Programable for a really wide range of setting conditions.

Review Date: 12 Dec 2024 | Sutter Instrument Co.

To pull sharpe and whole-cell patch pipettes

It is more stable then the p-87 model. The after sales help from Sutter Instrument Co. is very good; they have a pipette cookbook that is very helpful.

Review Date: 1 Dec 2014 | Sutter Instrument Co.

Electrophysiology

This machine is relatively easy to use (note: reading the instructions is extremely helpful, we all like to skip that step but with this piece of equipment it is tremendously advantageous.) Once you get the settings you like, you’re good to go. There are newer models which make the process much easier, however they are really expensive. For the money, this gets the job done just fine for us. Be sure to NOT bend the heating filament - once you do that, you'll introduce a whole lot of problems.

Review Date: 18 Feb 2014 | Sutter Instrument Co.

A very reliable instrument.

Review Date: 30 Nov 2011 | Sutter Instrument Co.

The Model P-97 micropipette puller is the latest generation of the Flaming/Brown type puller for fabrication of micropipettes, patch pipettes and microinjection needles. While retaining many of the features on the Model P-87, the P-97 offers improvements in mechanical, electronic and software design. The result is better control of the pulling process and a higher degree of reproducibility.

Features:

- Environmental chamber

- Programmable air pressure

- Memory storage for up to 100 programs

- Write protection and date stamp for each program

- Two symmetrical pipettes with each pull

- Two cooling modes: time and delay

- Preprogrammed sample programs for intracellular and patch pipettes. Special programming on request.

- Ramp test—self test for establishing program heat settings when a new filament or glass is introduced.

- Vacuum fluorescent display

- Constant current power supply for filament and pull solenoid

- Looping pull cycle for fabrication of patch type micropipettes

- Self-contained air supply with filtration system and humidity control

- Consistent and reliable electrodes with tip diameters less than 0.1µm

- Control over the time and pressure at which the air is delivered

- Optimized velocity sensing circuit for maximized sensitivity and reproducibility

- Quality control, SEM photograph of a tip pulled with each puller; criterion is tip measurement less than 0.1µm and typically is ~0.06µm