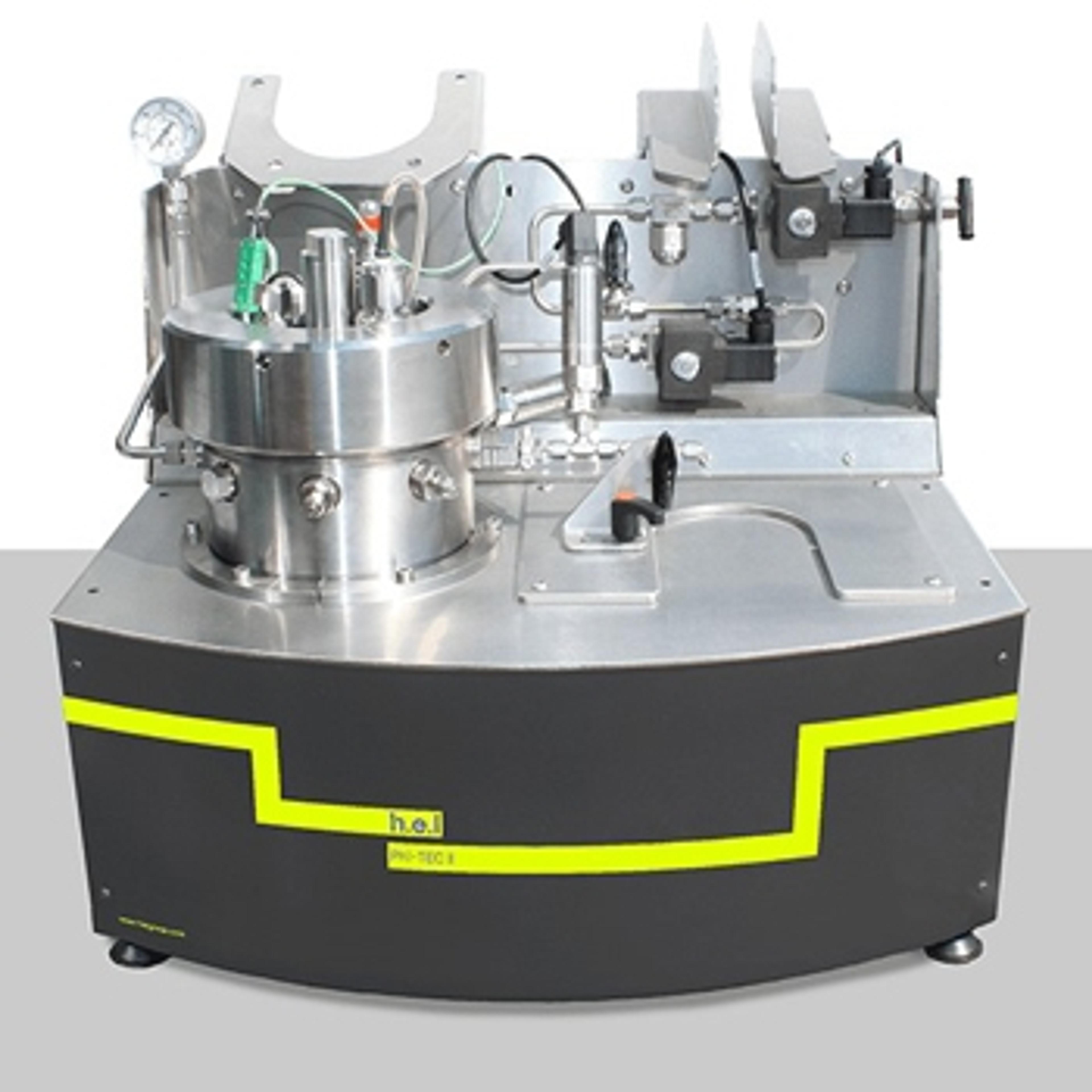

Phi-TEC II

The Phi-TEC II is an adiabatic calorimeter, which supports the use of low Phi-factor test cells. This allows for manufacturing plant conditions to be fully replicated on a lab-scale thus allowing thermal runaway risks to be simulated and assessed.

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Utilizing low-Phi factor cells means that the runaway rate is not tempered by the test equipment, and subsequently, the measured rate of pressure increase and final temperature (Tend) – along with the calculated Time to Maximum Rate (TMRd) and adiabatic temperature rise (∆Tad,d) – are representative of what would be expected to occur during a production-scale incident

The impact of different operating scenarios can be explored using the Phi-TEC II, and the data generated can be utilized to determine appropriate safety controls for the manufacturing plant, such as:

- Emergency and evaporation cooling

- Quenching

- Controlled depressurization

- Vent sizing (in accordance with DIERS methodology)

- Thus, the Phi-TEC II enables hazards to be fully evaluated, enabling their mitigation prior to scale-up.

Applications

- Hazard and Operability Assessment

- Plant-scale parameters from the laboratory

- The Phi-TEC II is a more advanced type of adiabatic calorimeter, which supports the use of low Phi factor test cells. This capability means that very little of the heat produced during a reaction or thermal runaway is consumed in warming the test cell. As a result, the runaway rate is not tempered.

The measured rate of pressure increase and final temperature (Tend), along with the calculated Time to Maximum Rate (TMR) and adiabatic temperature rise (ΔTad), are representative of what would be expected to occur during a manufacturing scale incident. Thus, the Phi-TEC II enables the hazards to be fully evaluated and explored, facilitating their mitigation prior to scale-up.

Safety by design

The data generated by the Phi-TEC II can be used to directly compare the impact of different operating scenarios. From this, the necessary safety controls for the manufacturing plant can be selected. Examples of these are:

- Emergency and evaporation cooling

- Quenching

- Controlled depressurization

- Vent sizing (in accordance with DIERS methodology)