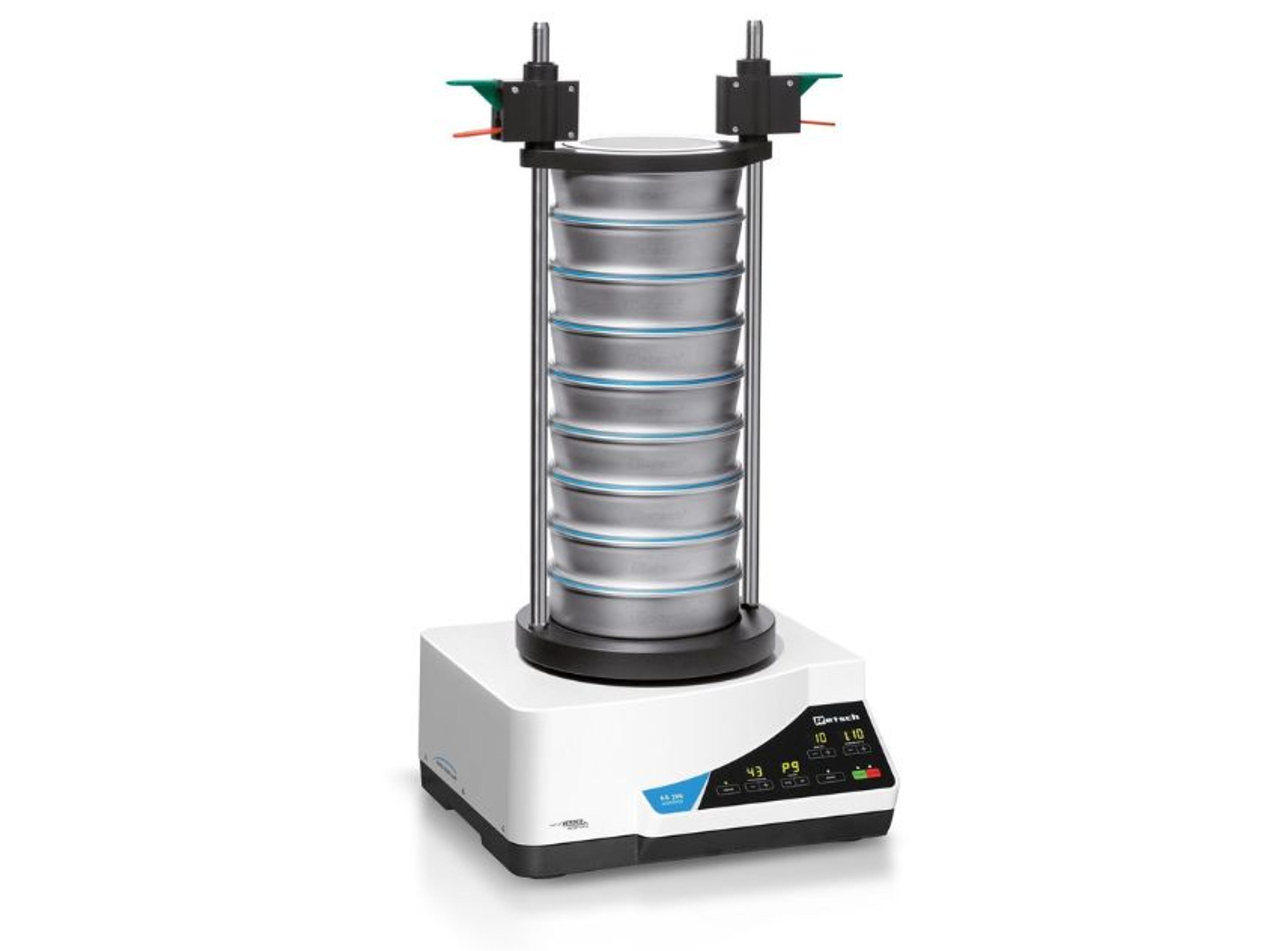

Planetary Ball Mill PM 100

Planetary Ball Mills are used wherever the highest degree of fineness is required.

Excellent performance and durability Ball mill

nanoparticle preparation

This is a very high-performing instrument and it is used for the preparation of nanomaterials including new crystalline phases of perovskite materials. We have used it extensively for making semiconductor nanoparticles, perovskite nanoparticles, quantum dots, etc. It is a very rugged and user-friendly instrument and we have been using it over a decade without much trouble. It's a highly recommended instrument for material research.

Review Date: 18 Oct 2024 | Retsch GmbH

it is a versatile instrument that cuts the grinding time by orders of magnitude.

Analyzing rock samples

The Retch ball mill we have purchased is easy to use in terms of loading and digital display control. The six griding vessels greatly amplify the number of samples that can be run at a given time.

Review Date: 10 Dec 2022 | Retsch GmbH

easy to use

size reduction of actives

Works very well

Review Date: 11 Aug 2022 | Retsch GmbH

Good accuracy and great quality of product,

Synthesis of nanoparticles

Absolutely good to use and easy to handle, long lasting compared to other brand. Highly recommended for regular users. Super maintenance support. I saw if any problem immediately take care from the maintenance department. My observation is very less trouble I faced with others brand.

Review Date: 10 Aug 2022 | Retsch GmbH

Great milling, perfect mixing of powders.

Wet milling and mixing of ceramic powder compositions.

This is such an effective planetary ball milling that I have ever used. As an academician and active laboratory researcher, I would choose the best product to conduct my experiments and The PLANETARY BALL MILL PM 100 is good example.

Review Date: 9 Dec 2021 | Retsch GmbH

Great results, would recommend

Synthetize quantum dots

It was really simple to use, it was easy to clean and it helped me with my thesis investigation. I would really recommend this product, it was also safe to use on the lab.

Review Date: 9 Dec 2021 | Retsch GmbH

Very useful results as per our measurements

Nanomaterials for hydrogen storage applications

I use Retsch ball mill PM100 from 200y onwards and preparing sample for hydrogen storage applications. This setup is basic but very useful to give adiquate application for the required materials.

Review Date: 9 Dec 2021 | Retsch GmbH

Planetary Ball Mills are used wherever the highest degree of fineness is required. Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processes. The extremely high centrifugal forces of the Planetary Ball Mills result in very high pulverization energy and therefore short grinding times.

The PM 100 is a convenient benchtop model with 1 grinding station.

Product advantages:

- Powerful and quick grinding down to nano range

- Perfect stability on lab bench thanks to FFCS technology

- Innovative counter weight and imbalance sensor for unsupervised operation

- Comfortable parameter setting via display and ergonomic 1-button operation

- Automatic grinding chamber ventilation

- 10 SOPs can be stored

- Programmable starting time

- Power failure backup ensures storage of remaining grinding time

- Reproducible results due to energy and speed control

- Suitable for long-term trials and continuous use

- 2 different grinding modes (dry and wet)

- Optional pressure and temperature measuring system PM GrindControl

- Measurement of energy input

- Wide range of materials for contamination free grinding

- Safety slider for safe operation