Powdernium Automated Powder Dosing System

Truly flexible, automated powder dispensing The Powdernium® offers an automated powder dispensing system, removing an often underestimated bottleneck, providing the highest level of performance, significantly increasing productivity and saving time. At the heart of this advanced automated powder dispensing workstation is a new state-of-the-art robotic system coupled with the proven Powdernium powder dispensing technology. Pow…

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Truly flexible, automated powder dispensing

The Powdernium® offers an automated powder dispensing system, removing an often underestimated bottleneck, providing the highest level of performance, significantly increasing productivity and saving time. At the heart of this advanced automated powder dispensing workstation is a new state-of-the-art robotic system coupled with the proven Powdernium powder dispensing technology.

Powder Dispensing: Unmatched flexibility

- Compatible with a wide range of materials and physical properties, including low-density to free-flowing, cohesive, micronized, etc.

- Consistent and accurate filling, with RSD between 1–5% depending on flow properties of powder.

- Compatible with almost any receiving container, including capsules size 000 – 4, bottles, vials, tubes, 96-wellplates, heavy reactor blocks, crucibles etc.

- Up to 80 capsules or more than two hundred powders can be stored on the machine on-line.

- Powder starting amounts from <100mg.

Automation: Multi-sample and batch dispensing

- State-of-the art automation including robust XY and two Z-Axis, allowing unattended runs day and night.

- Two grippers for destination receptacles such as tubes, vials, plates, reactor blocks and bottles, one gripper for powder dispensing.

- Each powder dispense is weighed on a balance, displayed and recorded automatically for reporting.

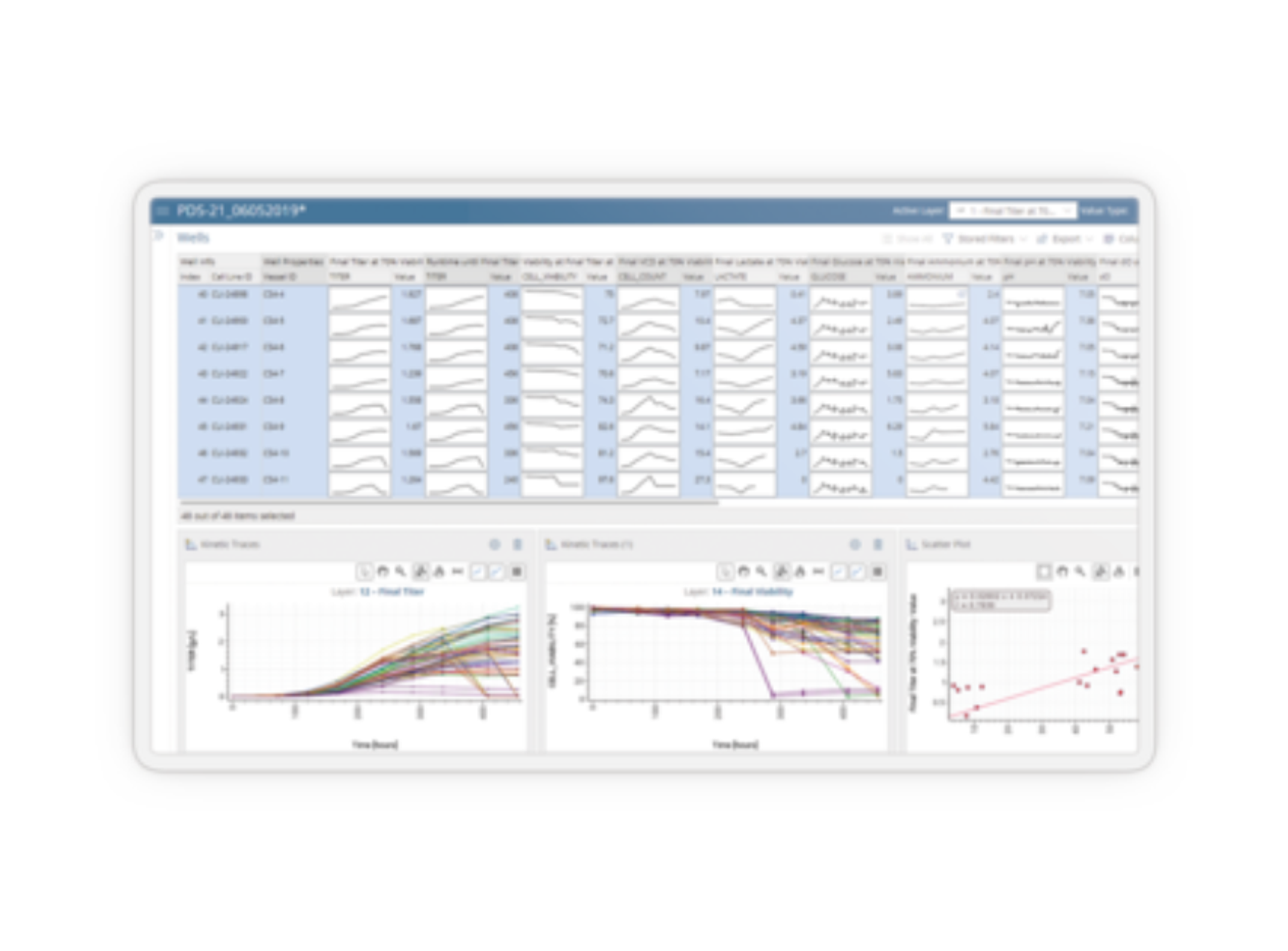

Control: Powdernium Easy-dose software

- Software provides data and information record about the dispensing cycle, including batch conditions and parameters.

- Define dispensing cycle or change application layout in minutes.

- Self-regulating software sets powder dispense parameters automatically, using optimization algorithms dynamically monitor and control any variability in powder properties during the filling process.