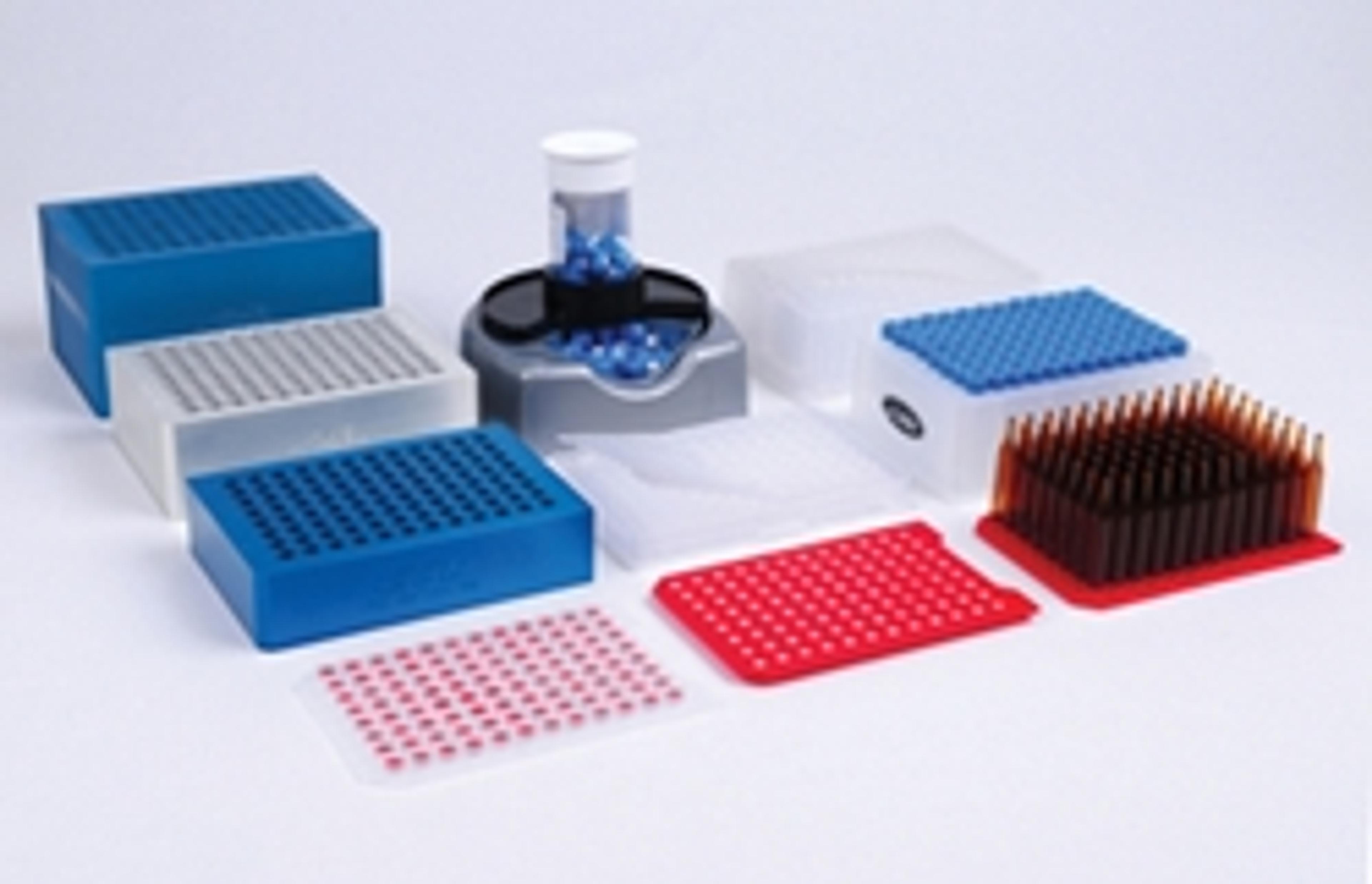

Unique Vial Solutions that Address the Needs of the Clinical Customer

14 Oct 2014

WHEATON has produced a range of new products that address the specific needs of the clinical laboratory, and other clinical life science customers. SelectScience interviewed Wayne Brinster, CEO of Wheaton, to find out how the company has listened to clinical scientists and created a product profile that is designed to address daily challenges in the laboratory.

SN: Can you tell me about the approach that WHEATON has taken in the design of its new product portfolio?

WB: For the past 125 years, Wheaton has specialized in designing and manufacturing plastic and glass containers with a wide range of closure systems. Initially the company served a wide array of applications, from soft drinks to cough medicine. More recently we have focused exclusively on the research, diagnostic packaging, clinical laboratory and specialty pharmaceutical industries across the globe, creating custom solutions that address the need for secure storage, transport and delivery of science’s most sensitive materials and precious specimens.

Internally, we continue to work hard to transition from supplying 'good quality products' to becoming recognized by our customers as the solution provider of choice, through relentless advocacy for them while developing and delivering complete solutions to their daily challenges.

We strive every day to create value for our customers by staying true to our legacy, while expanding our innovative solution base to meet the customers’ changing needs. We continue to build on our strengths in glass and plastic products, small instruments and services.

To build our position as the solution provider of choice, we will focus on the three business principles:

Customer Engagement We will be creative and adaptive in the way we go to market and in the way we serve customers, so that we get the best information on their exact needs. This will enable us to help them select the best solutions for their problems.

Portfolio Optimization As we actively listen to the voice of our customer, understand their needs and requirements then respond with the appropriate solutions, we practice what’s known as purpose built design.

Process Efficiency Our global customers rely on us to be both efficient and responsive, increasing the value of our offering by improving and aligning processes to better serve our customers.

SN: CryoElite Tissue Vials – Can you tell us a little more about how these vials were developed based on input from industry thought leaders? What are the advantages to the end user?

WB: Our CryoELITE Tissue Vials were specifically designed for effective cryopreservation of biological tissue specimens, because tissue is different from cells and biofluids and has particular requirements for cryogenic storage. With the WHEATON CryoELITE Tissue Vial‘s wide-mouth opening, 5mL capacity and high integrity closure, it offers researchers who work with tissue samples ease of use, convenience and security to ensure sample integrity.

Our vials meet USP Class VI classification and are manufactured from low binding, cryogenic-grade virgin polypropylene. They are also lot tested and certified to be free of pyrogens, RNase / DNase and endotoxins, the vials are tested for viable storage from -196⁰C to 121⁰C. With an external-thread cap design, the vial seal exceeds DOT and IATA classifications for diagnostic specimens and their transport and is capable of maintaining a secure closure during freeze/thaw procedures. The vials have a flat bottom and a stippled external surface to promote easier handling.

The advantage the WHEATON CryoELITE Tissue Vial offers is the ability to uniformly store cryogenic tissue samples in a secure, easily labeled and identified container while maximizing storage space. As the use of fresh frozen tissue has grown exponentially, space and organization are important considerations for many biobanks and biorepositories. In addition, with a container that offers a secure closure at temperatures as low as -196⁰C and meets DOT and IATA standards, researchers are able to collect, process, ship and store tissues all within the same container solution. With its wide-mouth and sturdy footing, the tissue can be manipulated in and out of the vial without damage to the tissue itself and without excess handling by the technician. Thus, CryoELITE Tissue Vials were developed in response to the need to maintain precious specimens in the most pristine form possible, leading to reproducible and viable data from downstream assays and studies, such as metabolomic studies with nuclear magnetic resonance (NMR) and liquid chromatography with mass spec (MS)/ tandem mass spec (MS-MS).

SN: MicroLiter Chromatography Vials are clean room packed; what benefits does this offer to the user?

WB: MicroLiter Chromatography Vials are the industry’s most versatile and innovative, designed for high precision, trouble-free operation for both GC and HPLC applications designed to work exceedingly well with autosamplers, and for high throughput chromatography applications. MicroLiter is the chromatography vial of choice for those applications where LOD and LOQ is pushed to the max such as DOA confirmation and vitamin D testing. They are pre-cleaned and packaged in a certified Class 10,000 clean room to minimize any potential for background noise, making them valuable for limited quantity specimens and unknown targets .

SN: Can you tell us more about the design of High Recovery Vials; what applications they can be used for, and how they improve efficiency?

WB: Standard, flat bottom vials create residual waste because it is not possible to remove all of the liquid from a vial using a pipette or syringe. To compensate for this, diagnostic reagent or pharmaceutical manufacturers must overfill vials to allow for an appropriate volume of the contents to be withdrawn. The design of the Wheaton High Recovery Vials provides downward drainage and pooling to allow for more liquid to be withdrawn. A recent study performed by Wheaton concluded that there was a 99.9% reduction in waste using High Recovery Vials compared to flat bottom vials. For expensive diagnostic reagents or pharmaceutical products, that can equate to the ability to fill considerably more vials with the same batch volume, and ultimately reduce manufacturing costs.

With thanks to Wayne Brinster, CEO of Wheaton. For more information on the products discussed in this interview, please click on the 'request information' tab below or see the list of products in this article at the bottom of this page.