Aeris Metals edition - XRD

Optimize the steel making process

The Metals edition of Aeris is a benchtop X-ray diffractometer for rapid and reliable analysis of sinter, direct reduced iron and retained austenite. Aeris is fully automatable and can easily be incorporated in industrial production control.

Cost-effective and high-quality metals production

X-ray Diffraction (XRD) is a key technology at every step of the steel making process. It is a valuable tool for rapid and accurate materials characterization of raw and intermediate materials employed in the steel making process (such as iron ore, sinter and direct reduced iron). Application of XRD is also ideal for quality control of the final products as it provides fast and precise quantification of metal phases such as retained austenite.

The Aeris Metals edition is your partner at every stage of the production process, from raw material to the final product

Features

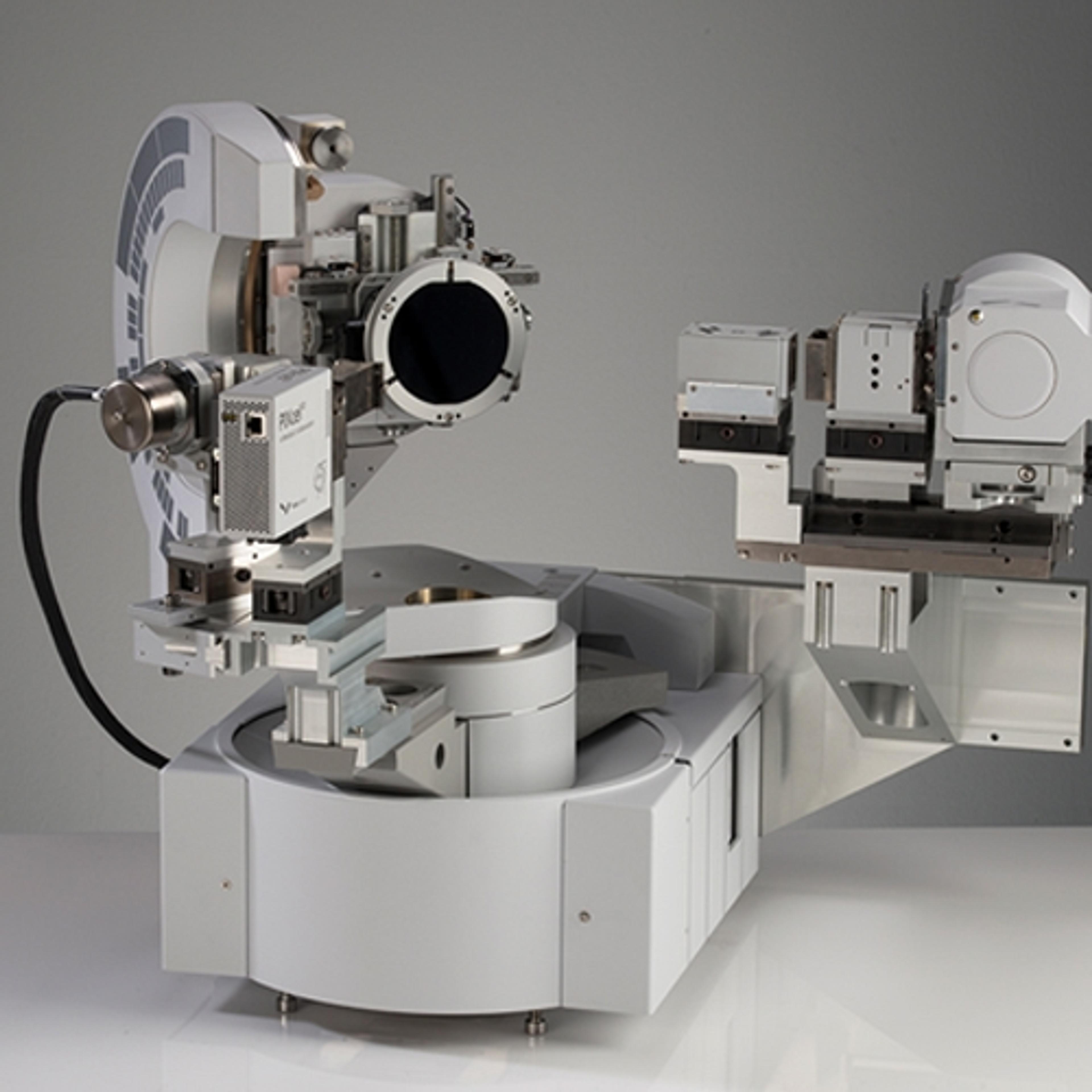

Seamless integration in automation

- The only automatable benchtop diffractometer for high sample throughput

- Aeris can be connected with a belt or a robot for fast and automated sample processing

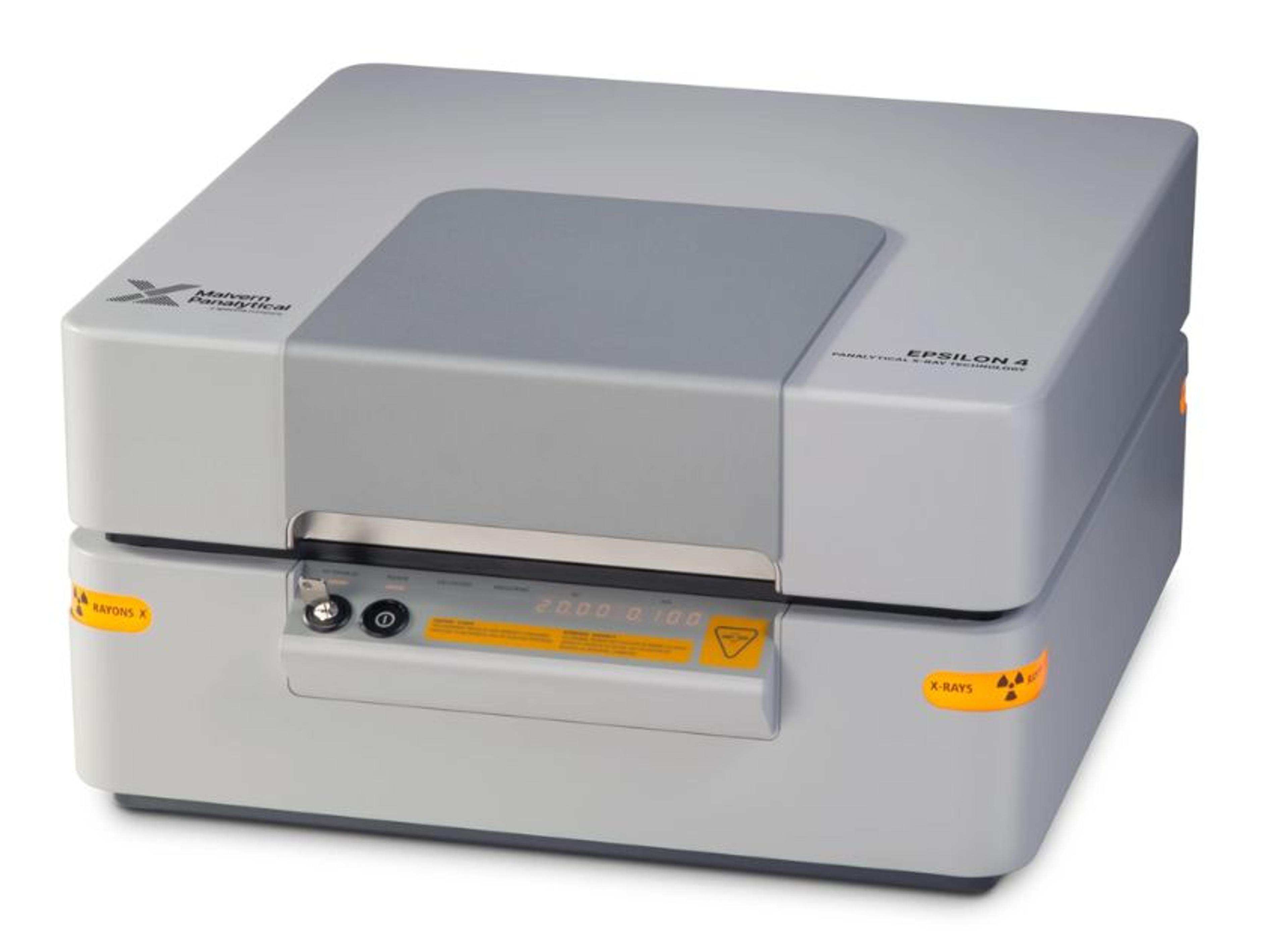

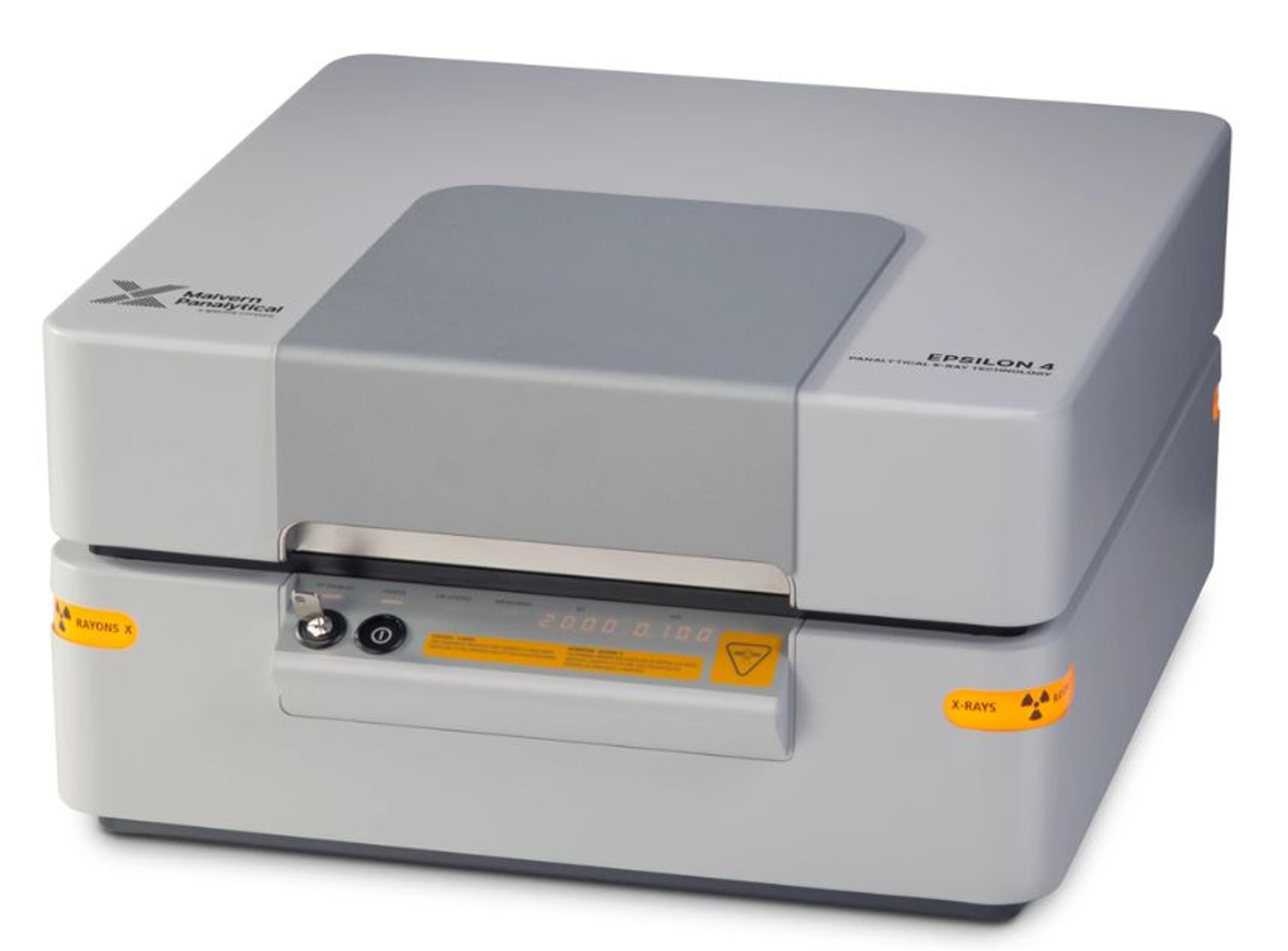

- The power of combining technologies

- The twin solution, Aeris and Zetium, provides full material characterization by adding information about elemental composition (determined by Zetium) to the phase identification from Aeris.

- Industry standard sample holders tailored to your needs

- Collection of 51.5 mm sample holders

- 40 mm sample holders