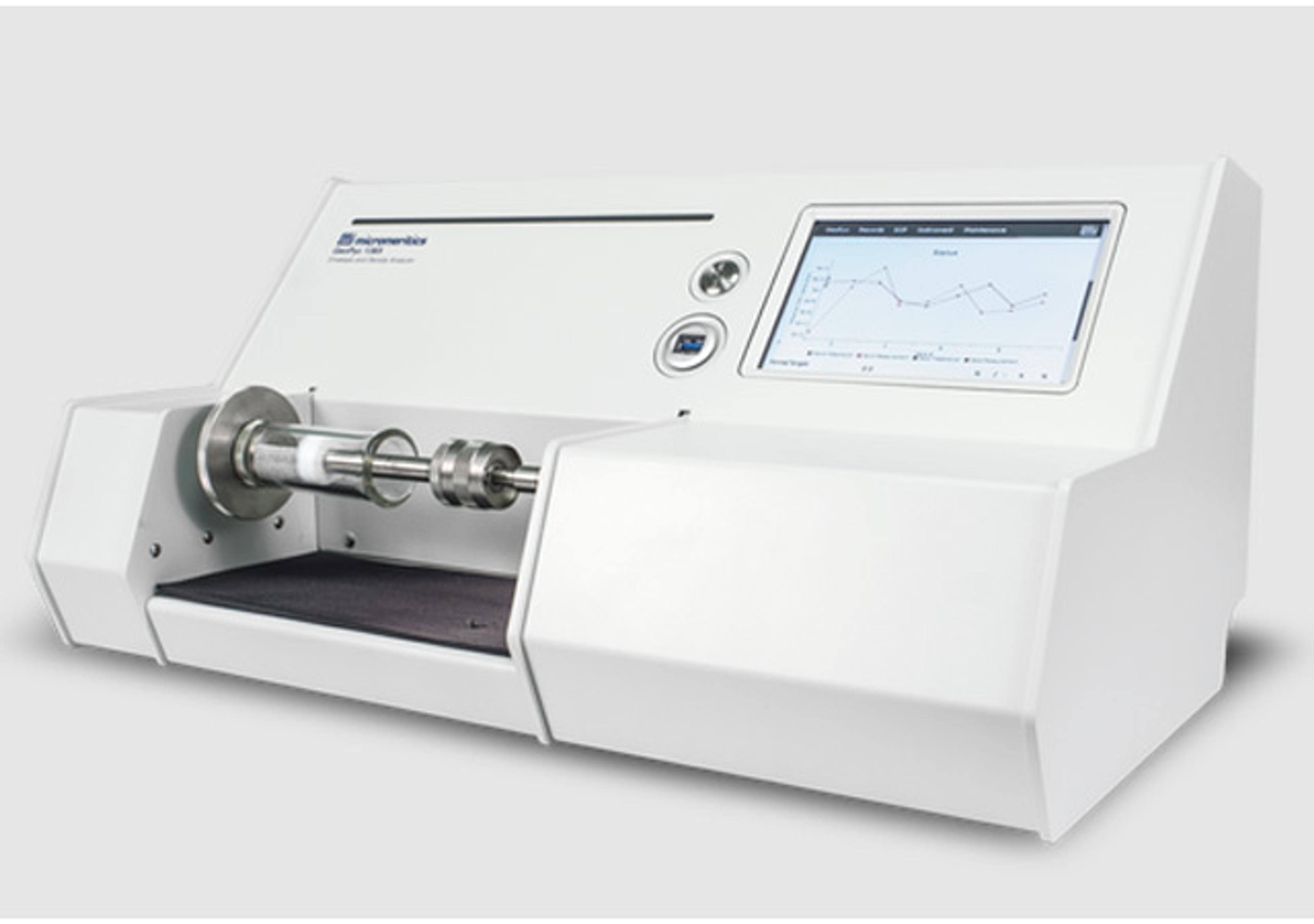

Automatic Cleveland Open Cup Flash Point Tester

The automated Cleveland Open Cup flash point tester accurately determines flash and fire point temperatures of viscous petroleum products including oils and bitumens over an extended temperature range.

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Gave perfect reading

To find flash and fire points

Easy to use.

Review Date: 22 Jul 2022 | Koehler Instrument Company

Easy to use and simple setup and installation.

Flash point testing

This is a very easy to use flash point system. The installation and set-up was very simple and being automated saves time in the lab. Entering the sample file name is a little time consuming but that gets easier as you use it. The only real negative is the sample probe is very delicate and situated in a place where it is easily broken. Replacement probes are very expensive.

Review Date: 16 Mar 2020 | Koehler Instrument Company

The automated Cleveland Open Cup flash point tester accurately determines flash and fire point temperatures of viscous petroleum products including oils and bitumens over an extended temperature range.

When examining highly viscous specimens, a preheating time and temperature are set in order to liquefy the sample for testing. The surface skin from bituminous samples can be removed with a skimmer.

The flash/fire point tests are simply conducted by mounting the flash cup filled with sample into the test position and selecting a pre-programmed test method or the search mode to determine an approximate flash point. The test results are automatically corrected to standard pressure (101.3 kPa).

Equipped with a differential Pt-100 RTD probe, the system is designed to duplicate the response time of a mercury-in-glass thermometer. Multiple sensors continually monitor instrument function, displaying an error message if a problem is detected.

The performance of the ionization sensor which detects the flash and fire points is continuously monitored, and the user is notified upon the need of replacement. If a flash is not detected 20°C above the expected flash point or at 420°C, then the test is automatically aborted for safety. The system is easily interfaced with an external PC for operation and method updates.

When performing a test, the system will display the stirring speed, temperature curve (also printed out), and current test status. The system alerts the user if the first application of the ignitor results in a flash or if no flash point is detected at the end of the test program. If a flash is not detected 30°C above the expected flash point or at 400°C, then the test is automatically aborted for safety.

Key Features:

- Conforms to ASTM D92 and related specifications

- Simple automation routine for easy operation

- Flash point operation between ambient and 400°C

- Flash and Fire Point detection by Ionization Ring

- Gas or electric ignition

- Data Storage: 200 results

- Automatic gas cut-off at the end of the test

- Equipped with Emergency Safety Switch