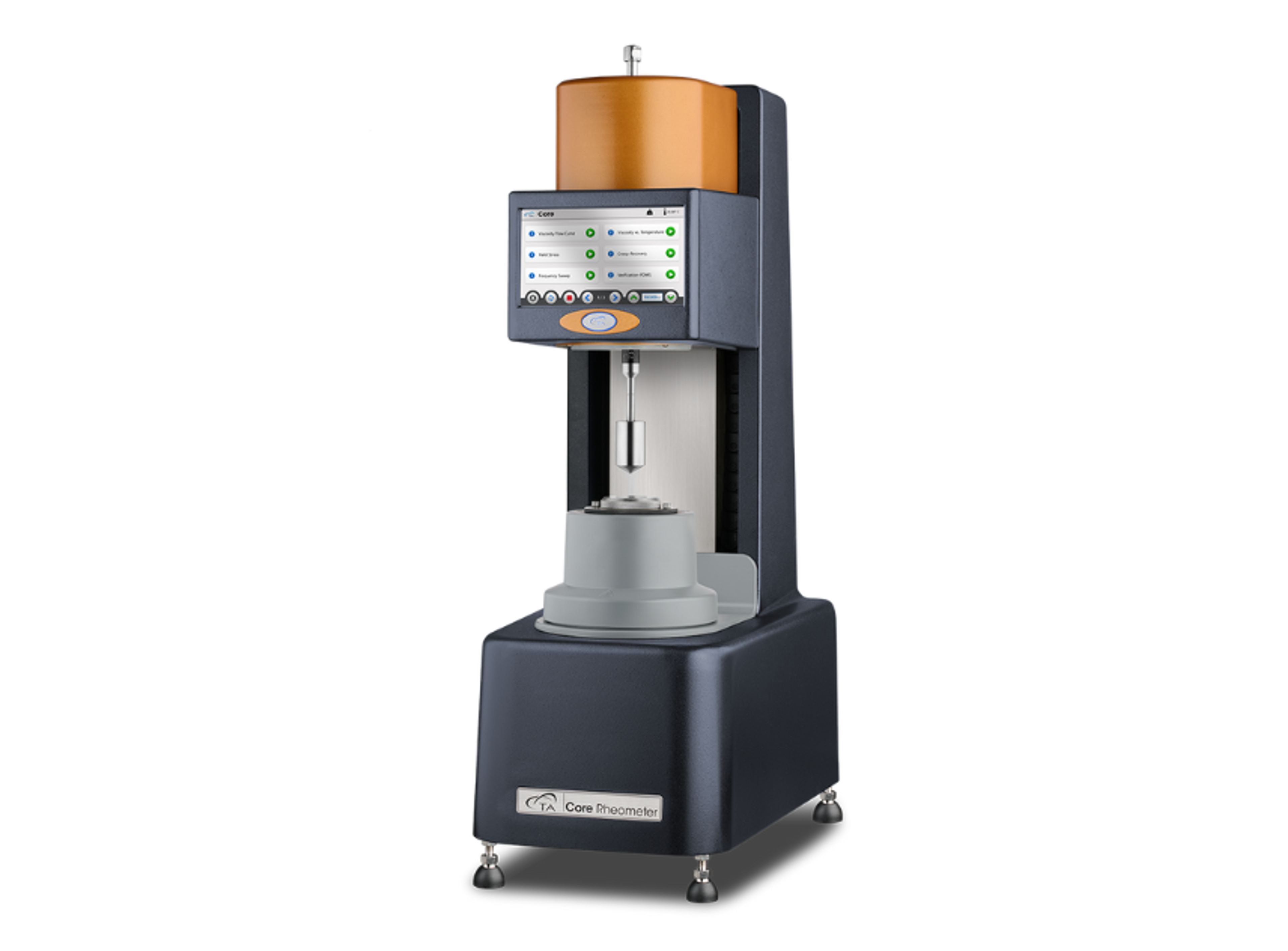

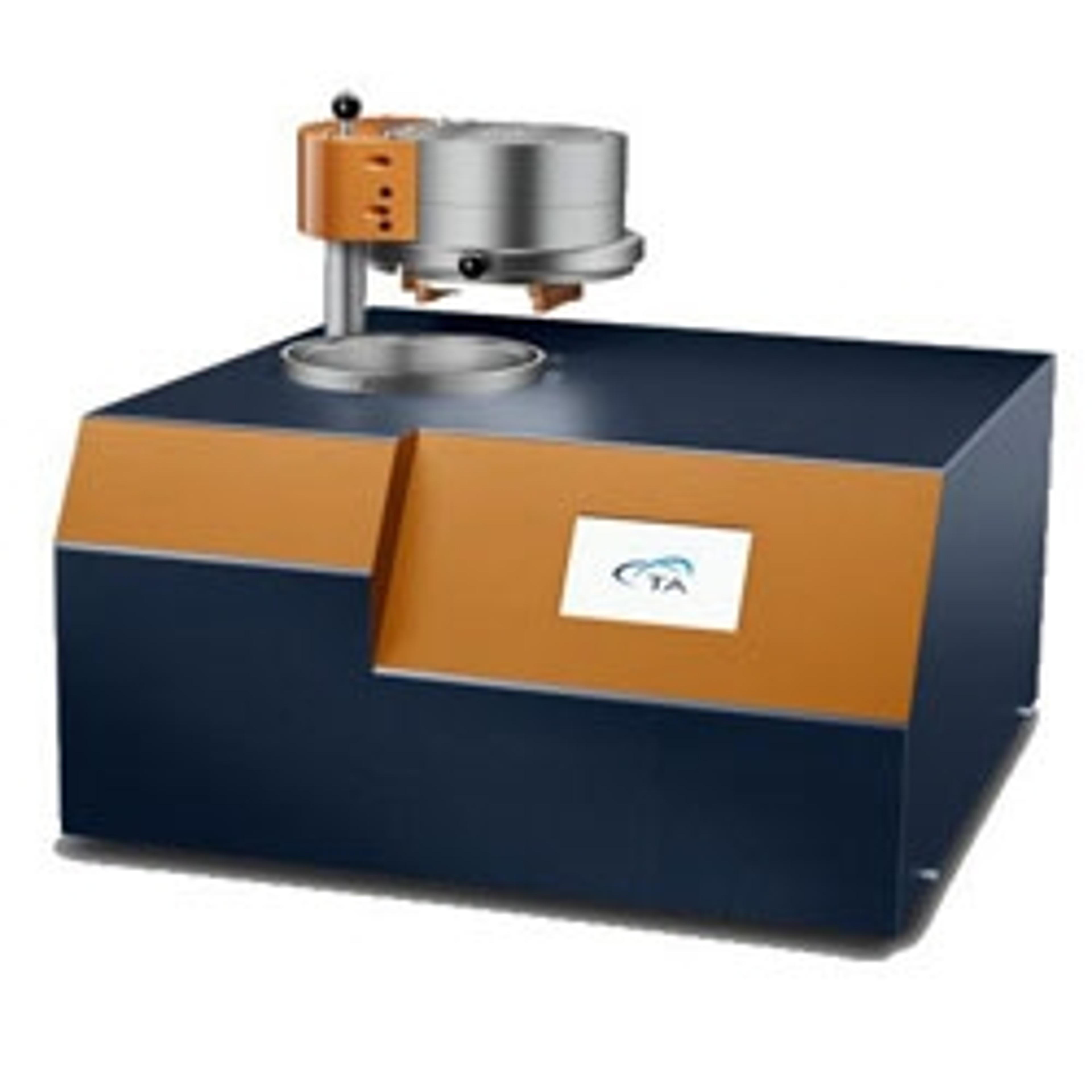

Mechanical Testing - ElectroForce™ Apex 1 Instrument

The TA Instruments ElectroForce Apex 1 Mechanical Testing Instrument empowers scientists, engineers, and technicians to assess mechanical properties efficiently and reliably through monotonic tests, fatigue studies, and other material characterization methods, all with minimal training required.

The ElectroForce Apex 1 Mechanical Testing Instrument enables customers across diverse industries to measure a wide range of mechanical properties easily and efficiently. Its enhanced stroke length and user-friendly design supports precise tensile and fatigue testing of high performance and lightweight polymers and composites including:

- Versatility – increased motor stroke range (100mm) expands testing of more materials across diverse industries, offering greater insights from one instrument

- Dynamic performance – completes fatigue testing for complex materials up to 30% faster, resulting in faster product development and validation

- Streamlined workflow – automated controls and fewer process steps reduce operator errors and ensure precision, enabling safe and confident testing

The ElectroForce Apex 1 Instrument features:

- Enhanced test setup and safety: Integrated motor brake, crosshead lock sensing, and setup mode reduces training and ensures sample and system protection.

- Dependable testing: Automated control system tuning and data acquisition enables confident characterization of materials, while minimizing the need to manage instrument operations.

- User-friendly features: SmartSwap™ Technology simplifies sensor and configuration, while the System Status Indicator provides quick visual feedback on instrument status.

- Exceptional accuracy: High-precision displacement sensor exceeds ASTM E2309 Class A standards with 1 nanometer resolution.

- Flexible testing: Available in 3 configurations (axial tabletop, axial floor standing, and axial torsional floor standing) and offers a broad range of accessories for real-world testing.

Ensure Product Performance and Durability

Material strength and durability testing is increasingly important for accelerating the development of products in demanding applications from airplanes to construction materials. Leading labs and manufacturers commonly use monotonic and fatigue testing to inform material selection and design, followed by component and product performance assessments.

Employing monotonic and fatigue testing on the ElectroForce Apex 1 Instrument early in development can reduce costs, by identifying and eliminating weaknesses in material selection and design, before the validation or post-launch phase.

Mechanical Properties - Material Characteristic Measured

Elastic (Young’s) modulus - Stiffness

Yield strength - Maximum stress before permanently deforming

Ultimate strength - Maximum stress supported by material

Elongation at break - Length change at breaking point

Fatigue life - Durability under repeated loading

Creep compliance - Deformation over time at constant load

Stress relaxation - Decrease in stress over time

Fracture toughness - Amount of stress to fracture

Fatigue crack growth - Amount cracks grow under repeated loading