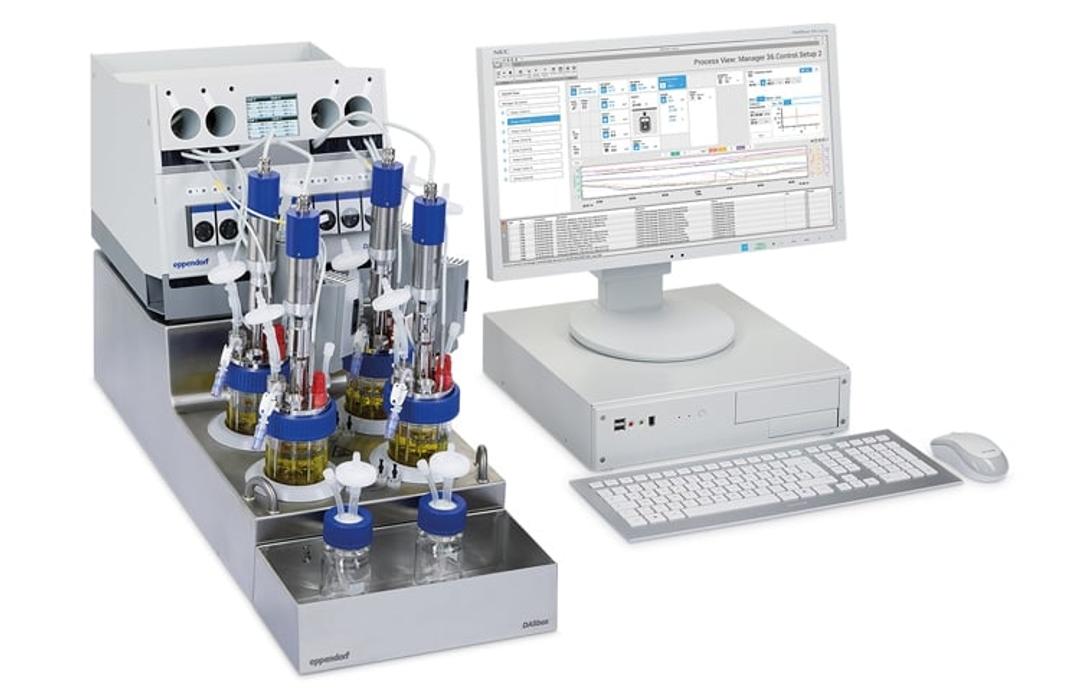

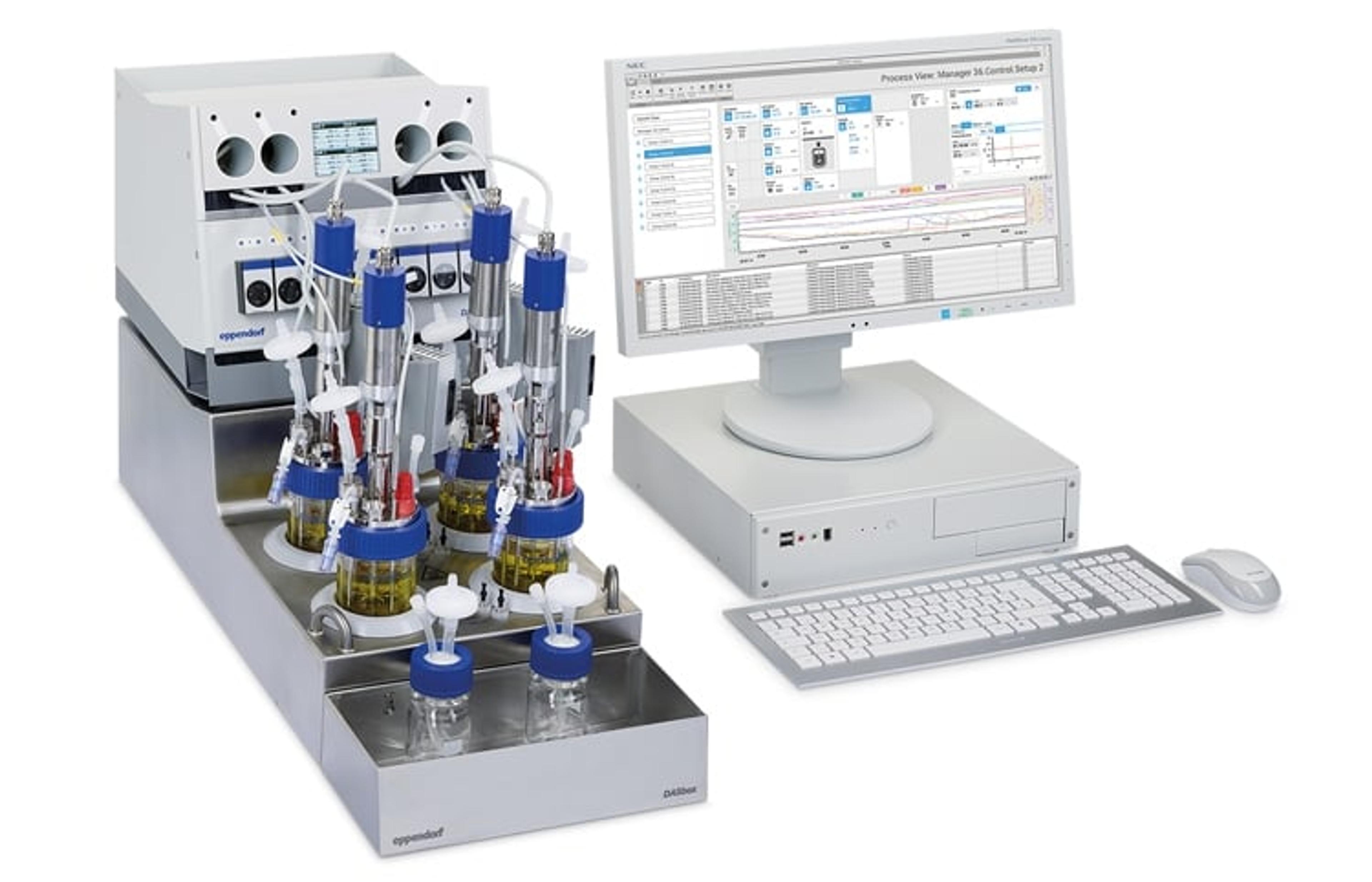

DASbox® Mini Bioreactor System

The DASbox is a unique mini bioreactor system suitable for microbial and cell culture as well as stem cell applications. It is designed as a 4-fold system with up to twenty-four parallel operating bioreactors. With working volumes of 60 – 250 mL the DASbox is the optimal tool for advanced process development and Design of Experiments (DoE) applications. All critical process parameters can be precisely controlled. Liquid-fre…

The DASbox is a unique mini bioreactor system suitable for microbial and cell culture as well as stem cell applications.

It is designed as a 4-fold system with up to twenty-four parallel operating bioreactors. With working volumes of 60 – 250 mL the DASbox is the optimal tool for advanced process development and Design of Experiments (DoE) applications. All critical process parameters can be precisely controlled. Liquid-free temperature control and exhaust condensation satisfy users with easy handling.

In addition to using industry standard glass bioreactors the DASbox can be equipped with Eppendorf BioBLU® 0.3 vessels, all fully instrumented single-use mini bioreactors.

Eppendorf DASbox® Mini Bioreactor System Features:

- Parallel set-up of up to 24 bioreactors;

- Excellent scalability and reproducibility in both microbial and cell culture applications;

- Supports industry standard glass bioreactors (DASbox Mini Bioreactor) as well as the BioBLU 0.3 Single-Use Vessels;

- Small working volumes save on the amount of cell material, media and supplements required;

- Extremely compact system with a footprint of only 7.5 cm (3 in) benchspace per vessel;

- Individual temperature control with liquid-free heating and cooling (Peltier);

- Liquid-free Peltier exhaust condenser with easy handling by automatic slide in activation and slide out deactivation mode;

- LC display with key process parameters and integrated alarm function simplifies monitoring;

- Fully mass flow-controlled gas mixing with individual gas mixture from Air, O2, CO2 and N2, each directable either to headspace or sparger;

- Standard sensors for precise measurement and control of temperature, pH, DO, level and ORP (redox potential); optical pH sensors available;

- Precise miniature variable speed pumps, continuous flow rates down to 0.3 mL/h;

- Sealed magnetic overhead drives for single-use vessels and direct overhead drives for autoclavable vessels; up- or downflow selectable;

- Optional pull-out system for enhanced accessibility of bioreactors and control unit.

Applications:

- Process development in cell culture and microbiology;

- Design of Experiments (DoE) Media optimization Clone and cell line screening, strain characterization.