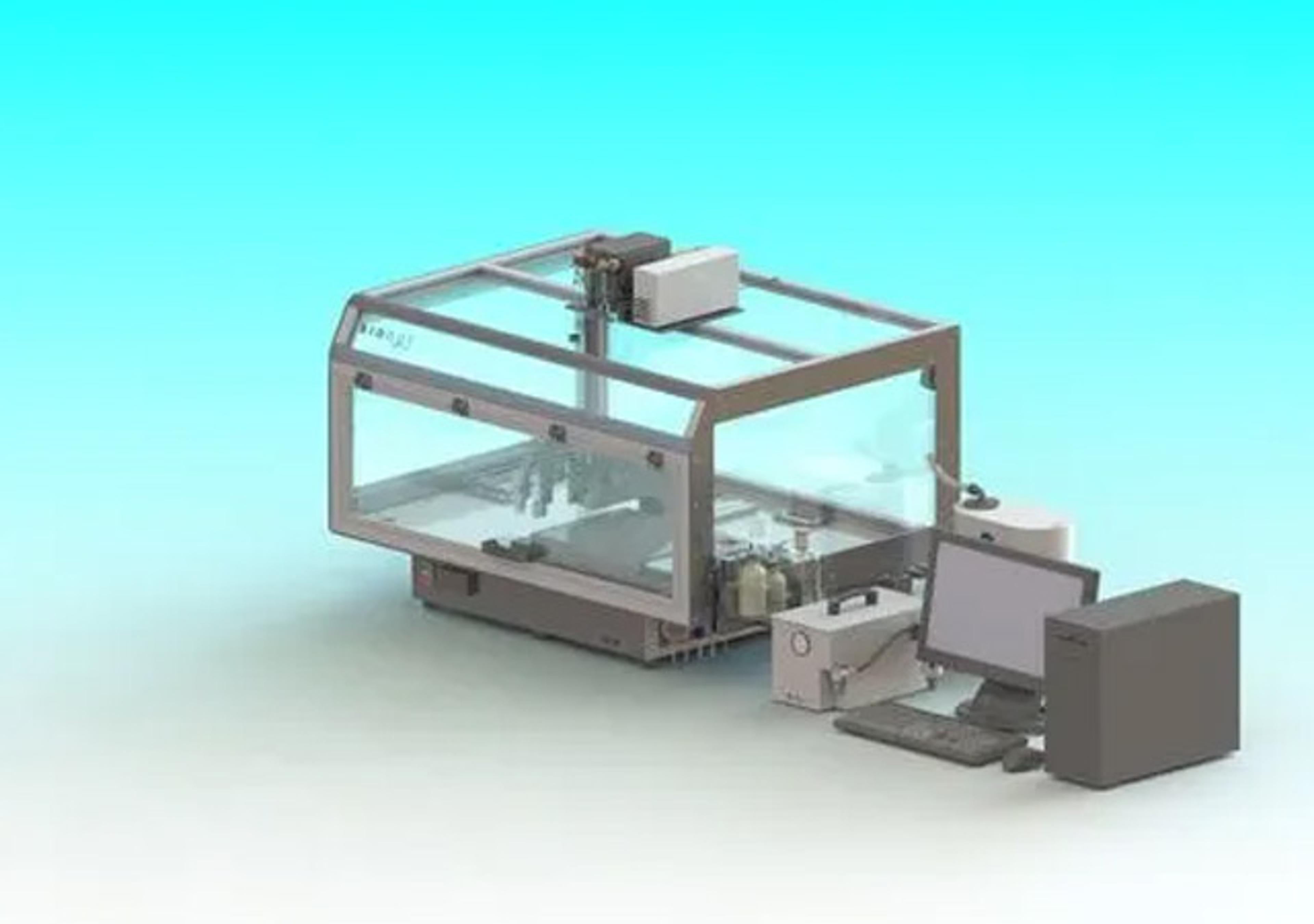

MagNA Pure LC Instrument

Robotic workstation for fully automated nucleic acid preparation and filling of LightCycler® Capillaries, 96-well PCR plates, and tubes suitable for the most commonly used PCR instruments Benefits Save time with rapid, fully automated isolation of high-quality DNA, RNA, and mRNA. Obtain reliable, reproducible results. Benefit from high flexibility in sample type and volume, as well as elution volume and post-elution p…

I love it!

Review Date: 7 Apr 2009

Robotic workstation for fully automated nucleic acid preparation and filling of LightCycler® Capillaries, 96-well PCR plates, and tubes suitable for the most commonly used PCR instruments

Benefits

- Save time with rapid, fully automated isolation of high-quality DNA, RNA, and mRNA.

- Obtain reliable, reproducible results.

- Benefit from high flexibility in sample type and volume, as well as elution volume and post-elution processes.

- Take advantage of software-supported setup of reagents and disposables.

- Automate pipetting of PCRs into LightCycler® Capillaries (LightCycler® Sample Carousels), LightCycler® 480 Multiwell Plates (96-well), PCR plates or strips, or tubes.

Product Description

The MagNA Pure LC Instrument is a tabletop instrument for rapid, cross-contamination-free preparation of nucleic acids, and PCR setup. A completely closed housing, automatic clot and tip loss detection, as well as sample tracking make the MagNA Pure LC Instrument a true “walk-away” instrument. Filtration, centrifugation, and other manual steps are completely eliminated. No vacuum pumps or tubing are required. With the piston-driven 8-channel nozzle head and positive-displacement liquid handling, the risk of cross-contamination is reduced to an absolute minimum. UV decontamination and the HEPA-filter system ensure maximum safety for samples and the environment. The inside of the housing can be easily cleaned with commonly used disinfectants. The MagNA Pure LC Software supports a bar-code reader and bar-code printer, as well as a pager so that the user can be notified about the status of the instrument and isolation processes.