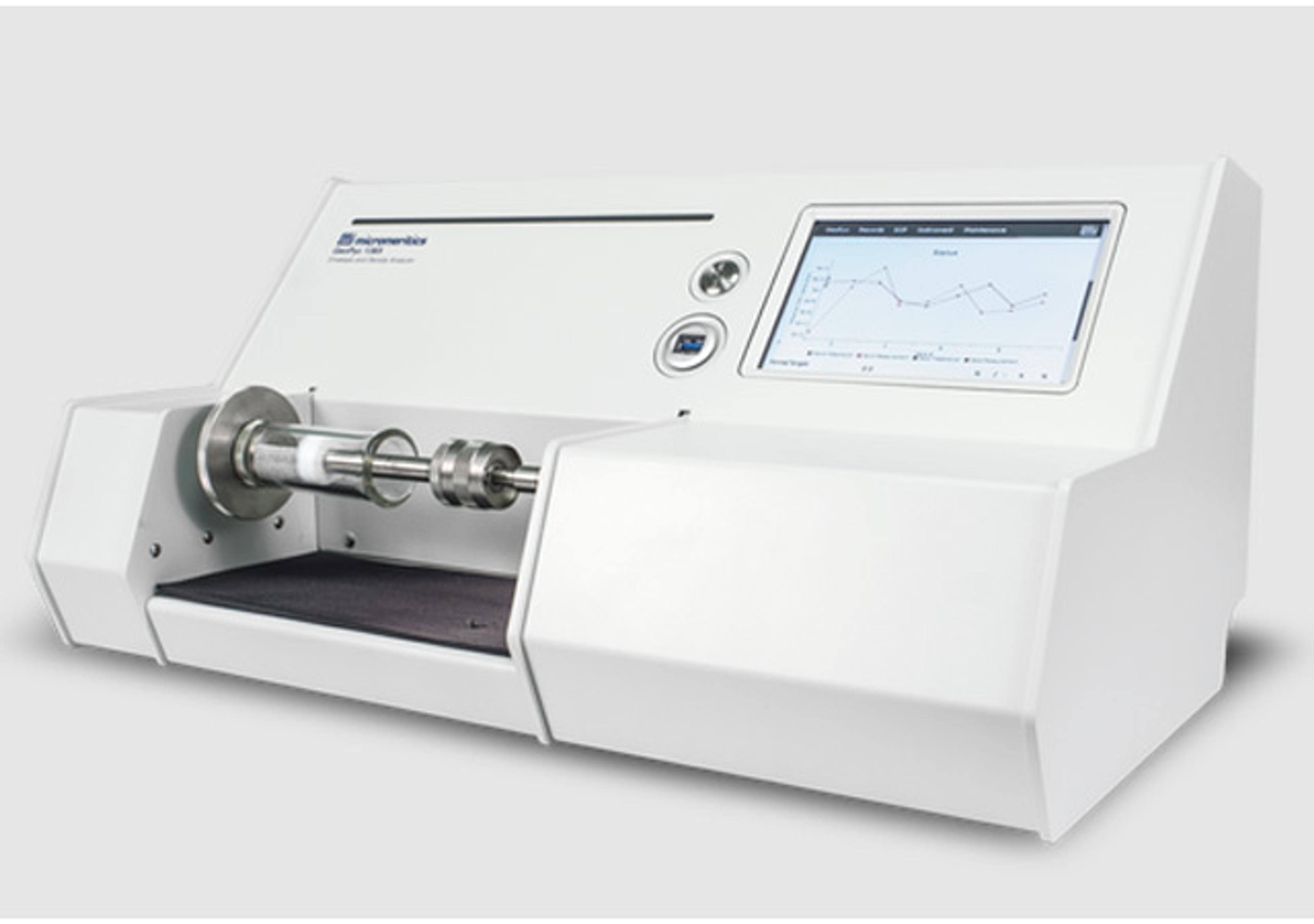

TG 209 F1 Libra

The vacuum-tight thermo-microbalance for highest demands

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

Very useful to a polymer or rubber laboratory as well in other applications.

Polymer (rubber) industry

Easy to use, reliable, fully automated. Standard analysis in different atmospheres as well in vacuum, linkable with FTIR/MS and has microbalances inside.

Review Date: 26 Oct 2020 | NETZSCH-Gerätebau GmbH

Faster and more comprehensive characterization of materials

Based on over 50 years of experience in thermogravimetry, NETZSCH has developed the thermobalance TG 209 F1 Libra®. This instrument allows for analyses to be carried out even faster, more accurately, and across an extended temperature range.

Twice as fast by means of BeFlat®

In contrast with other thermobalances, no time-consuming baseline determinations need normally to be carried out with the TG 209 F1 Libra® prior to a measurement. The unique BeFlat® function of the Libra automatically compensates for any external factors influencing the measurement. This cuts work hours by up to 50%, leaving more time available, for example, for further measurements.

20 times faster due to high heating rates

The heart of the TG 209 F1 Libra® is the micro furnace made of high-performance ceramics. It not only allows for a wider sample temperature range of up to 1100°C, but also for heating rates of up to 200 K/min. The user can thus receive the results of the analysis – even at highest temperature – within a few minutes, i.e. 20 times faster than for other thermobalances.

More comprehensive and faster characterization by patented c-DTA®

With the TG 209 F1 Libra®, the sample temperature is measured directly. Endo- and exothermal reactions can now be detected and show, for example, the melting point of the sample, in the evaluation. This yields considerably more information on the sample behavior without having to carry out further measurements.

High-performance ceramics for a long lifespan

The lifespan of the new, especially designed ceramic furnace – even when investigating materials containing corrosive components – is many times longer than that of conventional thermobalances. The analysis of fluorinated or chlorinated polymers is therefore no problem. The reaction and purge gases flow in the natural, vertical direction. Condensation on measure-relevant components (sample holders) can therefore be excluded. This not only is gentle on the material, but also prevents occurrence of the dreaded memory effect which can distort subsequent measurements in conventional systems.