Products & ReviewSpectroscopy

X-Sential™

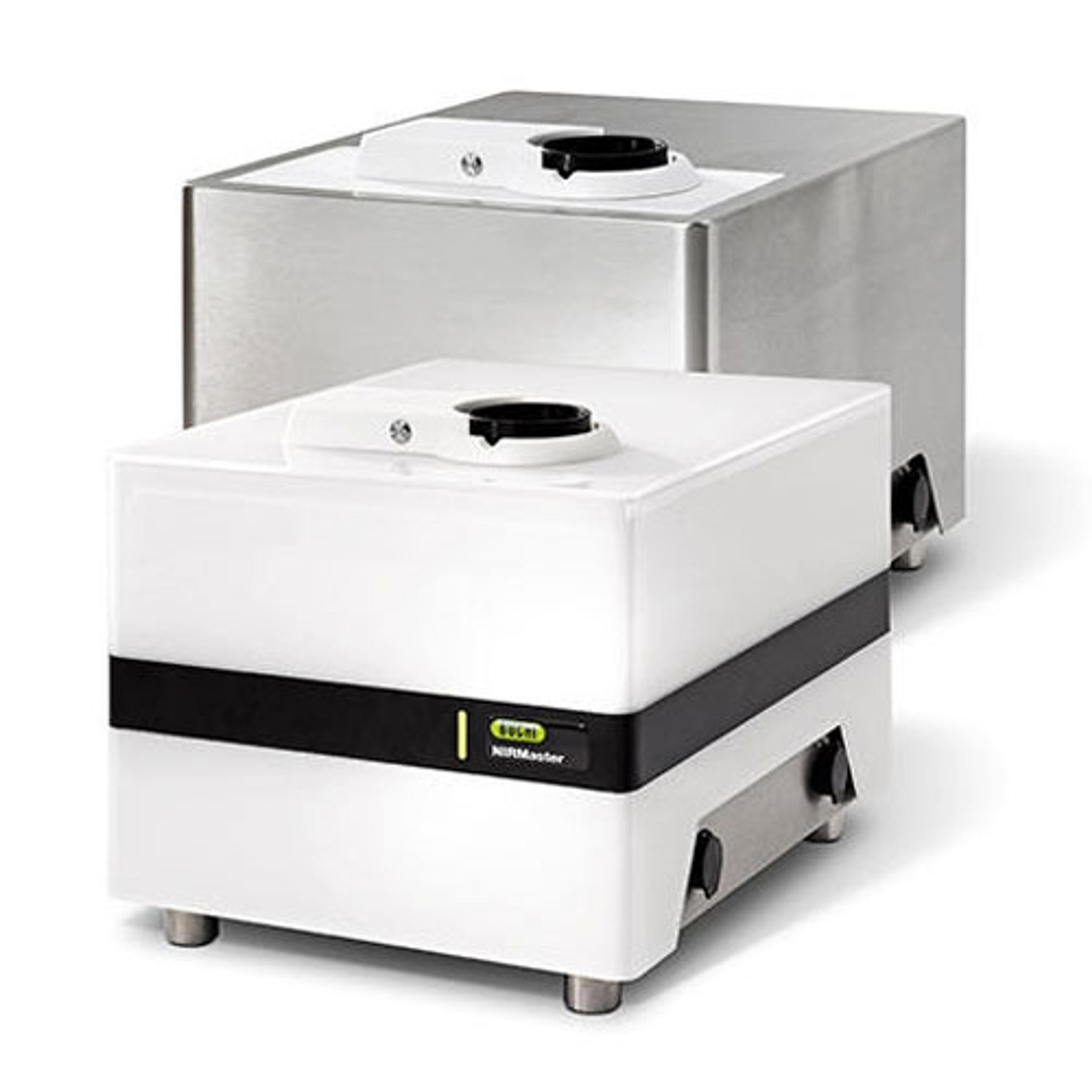

BUCHIAvailable: Worldwide

Everything essential for efficient process control

Careful monitoring of basic parameters such as moisture, fat, or protein is needed to quickly and efficiently correct deviations in the manufacturing processes. Our X-Sential™ NIR system has been developed and designed as an economical, fit-for-purpose, high quality process sensor. Benefits include:

- Ease-of-use - Thanks to its AutoCal functionality, there is no need for expert knowledge to operate the NIR unit. The process sensor is easily adaptable into quality control routines and directly on production lines. NIR-Online offers you additional optional HMI solutions

- Cost-efficiency - With a fit-for-purpose design, the average payback period for the NIR system is less than one year. No commercial calibration databases or expensive in-house callibrations are required. The process sensor enables you to measure multiple basic quality parameters of raw materials and finished products in large quantities. With data in seconds, you can make corrections to the production process in real-time, saving time and resources by minimizing re-working.

- Robustness - NIR-Online X-sential™ has a dust and water jet-protected sensor enclosure (IP69/X9K), so it can be used under harsh conditions. With temperature-stabilized spectrometers, the sensor can be used in a wide range of ambient and product temperatures. The NIR system is perfectly suited to integration in fast, fluctuating, or discontinuous product flows.

- Diode array technology - As a spectrometer with moving parts, the sensor can be used under harsh industrial conditions, including vibrations, extreme temperatures or humidity and to detect fast-moving products, such as those on pipes or conveyor belts

- Dual lamp - allows for maximal system availability

- Hardware process integration - Ideal for use with solid, liquid, pasty, viscous, or corrosive samples at a broad range of pressure and temperature conditions

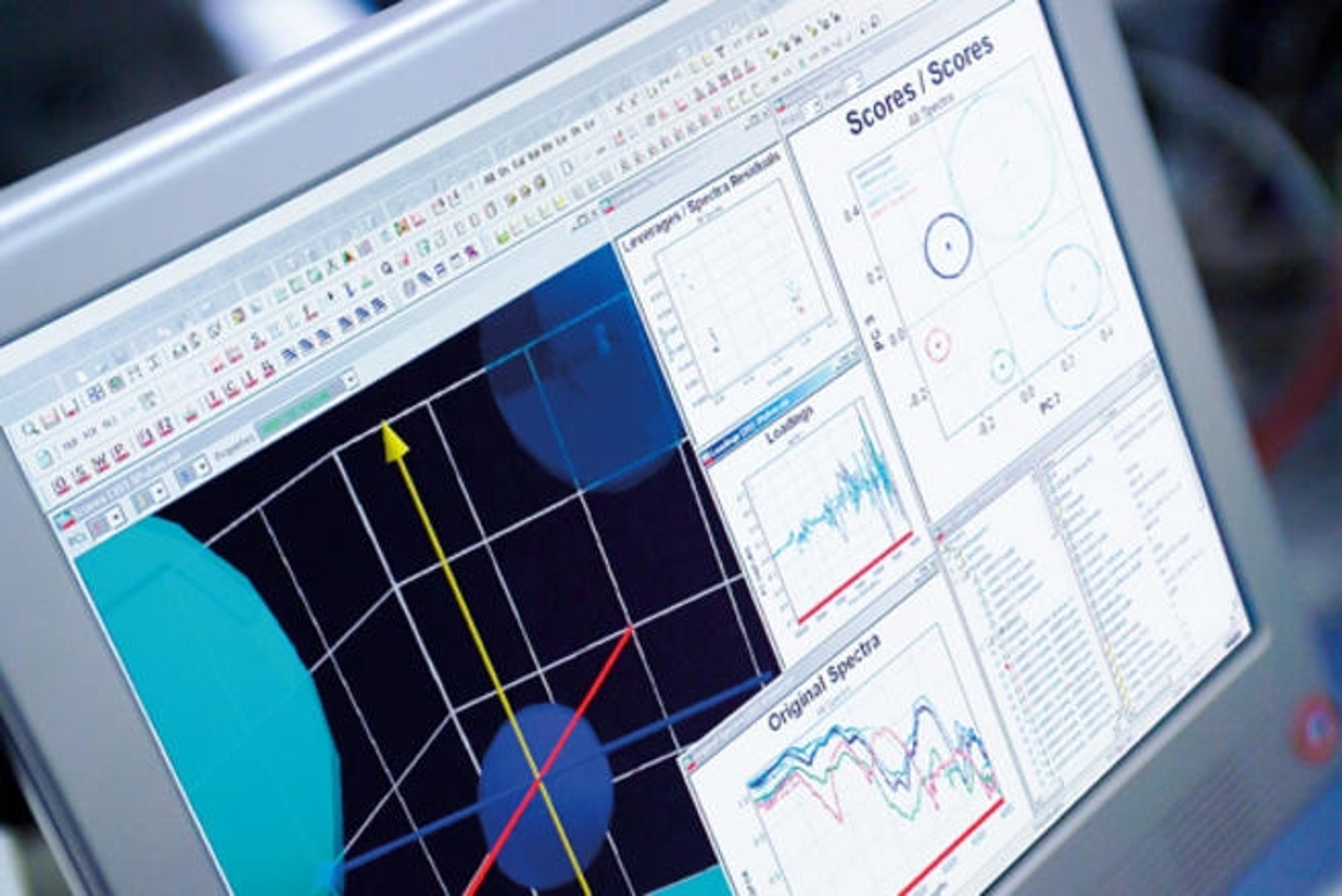

- Software process integration - Numerous interfaces for the convenient transfer of acquired data to process control systems, including TCP/IP, OPC DA, Modbus TCP, Profibus, and analog output. Benefit as well from optional device-independent HMI solutions.