Bioreactors pave the way for a more sustainable and resilient world

1 Oct 2023Although bioreactors have only been in the spotlight in the last few decades, we should remember that they have been in use for thousands of years for fermentation of food and medicines. However, it was not until the 1950s that bioreactors started to gain momentum in industries such as pharma and biotech. Since then, they have evolved significantly in design, scale, and applications, becoming indispensable tools for producing a wide range of biological products including the manufacture of therapies and biofuel. Sitting at the intersection between science and engineering, bioreactors now hold the potential to address some of world’s most critical issues - climate change emergency, waste management crisis, rising global health concerns included. Additionally, their unique adaptability offers opportunities to make significant changes to the industry, paving the way for sustainable practices and creating a more resilient world.

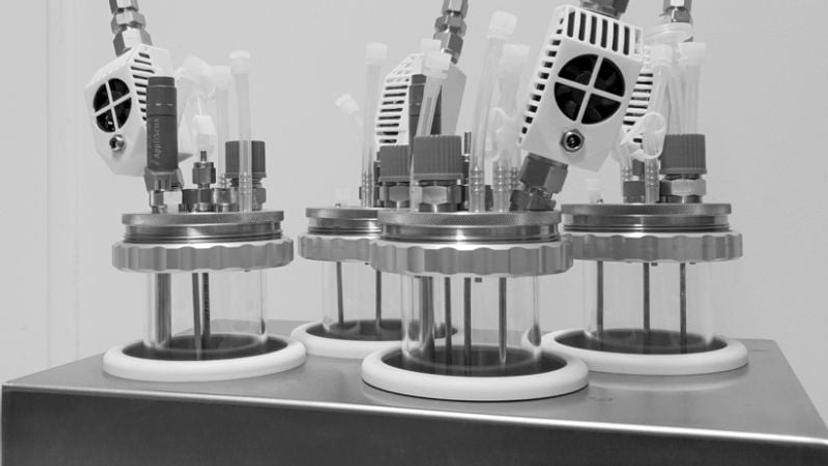

H.E.L’s BioXplorers

Supporting a healthier, more sustainable, and safer world, H.E.L Group (H.E.L) is a leading supplier of instrumentation, software, and equipment in laboratories and testing facilities around the world. These products and services are used to optimize the efficiency, safety, and productivity of key processes across chemistry and biology applications, with a focus on providing proprietary automated solutions for the battery, pharma, biotechnology, chemical and petrochemical sectors.

Bioreactors are a cornerstone for current biotechnology and industrial microbiology, and are fundamental in the synthesis and production of chemicals such as enzymes, vaccines, antibiotics, and proteins. At their very core, bioreactors are vessels designed to provide a controlled environment with the ideal conditions required for the cultivation and growth of microorganisms, cells, or enzymes. Therefore, the design and operation of bioreactors needs to allow the optimization and control of culture conditions, such as pH, temperature, oxygen concentration, and nutrient supply, for the maximization of the quality and quantity of the desired product.

H.E.L Group’s BioXplorer bioreactors enable automated, parallel experimentation from 50ml to 5L, ideal for small-scale bioprocess development. These adaptable bioreactors are suitable for microbial cell line/strain screening, research, and optimization. Through customer collaboration, H.E.L designed a high-pressure bioreactor system, the BioXplorer 400P, ideally suited for applications including cell-free enzymatic reactions, bio-product manufacture, process scale-up/scale-down, and gut microbiome simulation. The BioXplorer is also designed for gas fermentations, such as decarbonization of waste gaseous effluents, or the production of high-value products from H2 and CO2, an important step in the fight against climate change.

Available products

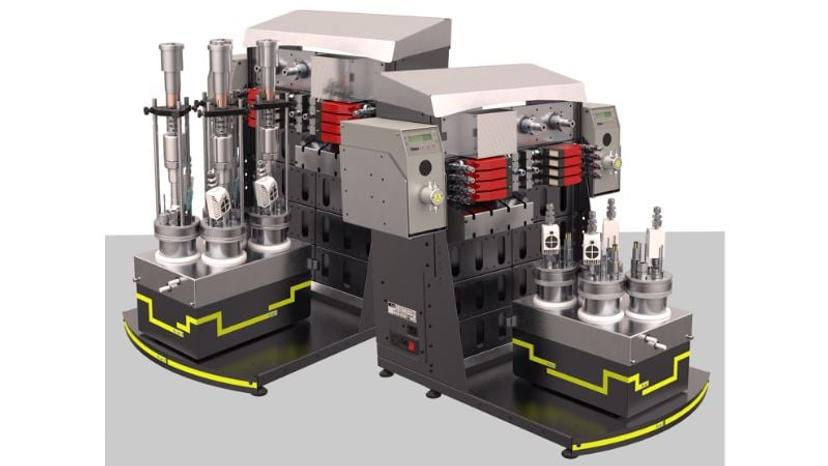

Launched in June 2023, the BioXplorer 400XL and BioXplorer 400P are the newest innovative products in H.E.L’s bioprocessing portfolio. These latest additions to the BioXplorer product range further enable efficient and cost-effective development and optimization of bioprocesses. The unique lid design of the BioXplorer reactors unlocks the versatility to choose from a range of implements, including probes, and the possibility of having one or more spargers. This, in turn, can be used to inject different gases into the liquid medium, maintaining a strict control of concentrations.

The BioXplorer 400XL is equipped with eight 500mL bioreactors, supporting the fast optimization of critical parameters for aerobic fermentations. This is achieved through the systems' ability to run different conditions in each of the individual reactors simultaneously. The systems are controlled by H.E.L software, monitoring parameters of interest, automatically acting on them and recording all experimental data - thus facilitating complete automation of fermentation experiments.

Bioprocess scientists are more frequently turning to pressurized systems to increase the solubility of gases and accelerate gas-dependent reactions. The BioXplorer 400P can operate safely under pressure, up to 10 bar. The BioXplorer 400P is the ideal solution for the optimization and scale-up of such processes. Its modular design can be supplied with a range of probes, gas feeds and liquid feeds, enabling it to be tailored to precise parameters, maximizing functionality and ease-of-use while minimizing bench space requirements and costs.

Supporting industry and academia

In a recent collaboration with Stéphane Guillouet, Professor at INSA Toulouse, scientists used H.E.L’s BioXplorer 400P as part of their metabolic and biochemical engineering research. Using a commercial gas mix and atmospheric pressure, the research group was able to produce 0.2 g/L of C.necator biomass. Using three spargers, the amount of biomass increased over an order of magnitude, up to 3 g/L (DCW). This was achieved by supplying higher concentrations of H2, but maintaining the O2 concentration below 2%, preventing enzymatic inhibition, and importantly, explosive gas mixes. Using CO2 as carbon source, and the oxidation of H2, Guillouet et al, achieved isopropanol production with levels comparable to those using sugars as a carbon source, avoiding competition with resources for human feeding.

Additionally, H.E.L has collaborated with organizations including Solugen, working on decarbonizing the chemical industry with the high pressure BioXplorer systems. These pressurized bioreactors have also been utilized at Newcastle University to increase process efficiency in the production of high-value products from waste gas. At Tufts University, they have used the H.E.L BioXplorer platform to simulate the gut microbiome, investigating the effects of diet on microbial and functional diversity of the gut ecosystem. It is close collaborations like these that drive H.E.L and help us create a healthier, sustainable and safer world for everyone.