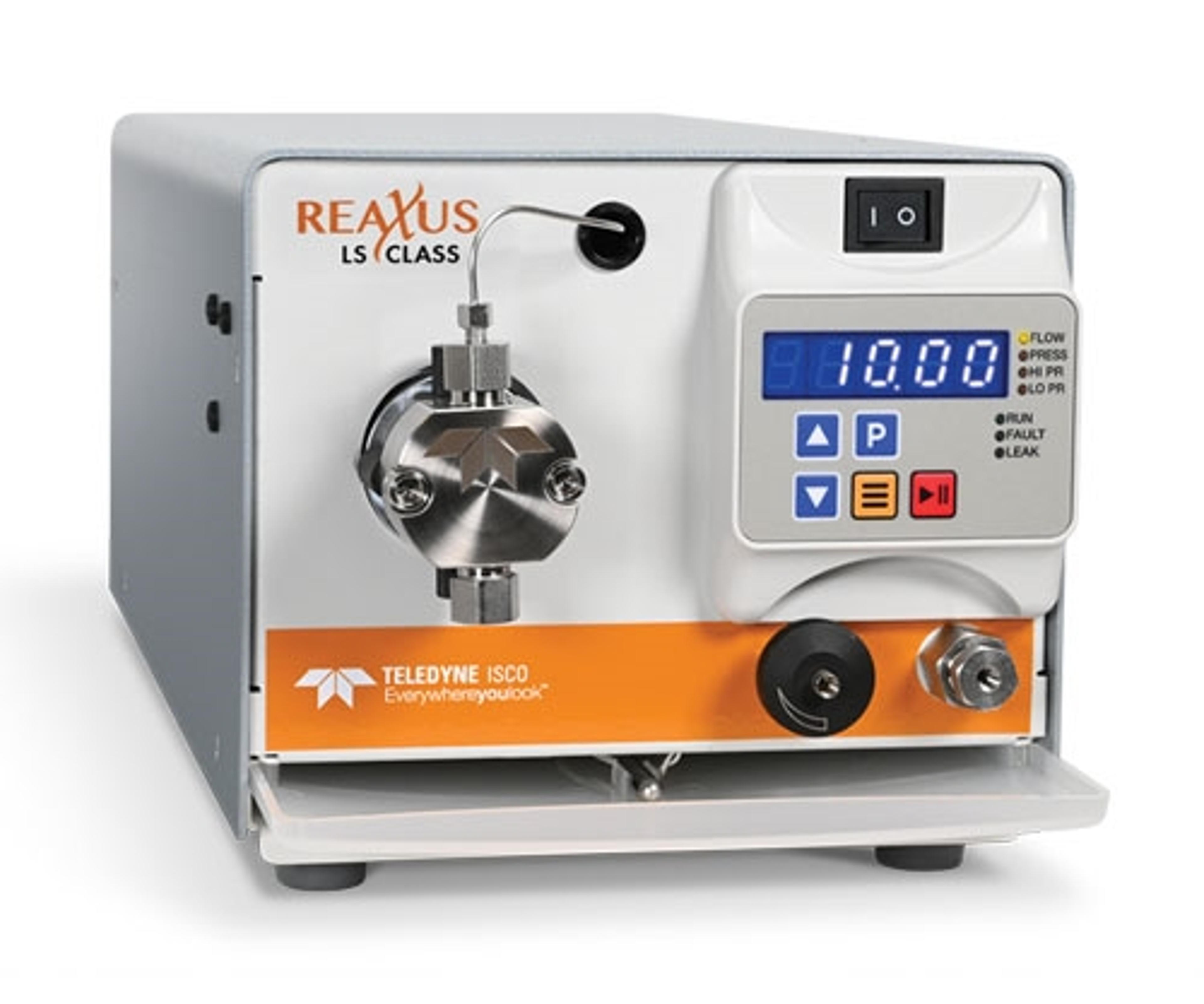

1000HLf Syringe Pump

ISCO HLf-Series pumps give you the same accurate, predictable flow and pressure control as our standard D-Series, while conforming to safety standards for use in UL Class I, Division 2, Groups A B C & D, T4 environments. The hazardous location rating is achieved through internal design modifications including the use of brushless DC motors.

The 1000HL pump handles a broad range of fluid delivery and dispensing applications in locations where equipment must be rated for Class 1, Div 2 (gas groups ABCD).

Flow rate is settable from 0.100 ml/minute up to 244 ml/minute, with a 2000 psi (138 bar) pressure limit. Refill takes only about 4 minutes, and the A1000HL dual-pump system provides non-stop continuous flow with alternating refill and delivery. The programmable HL controller gives you instant access to menu screens - even when the pump is running – to enable on-the-fly changes in limits and other operating parameters. An optional extension cable for remote operation lets you locate the pump up to 50 feet from the controller. Wetted materials are compatible with most aqueous and organic liquids, corrosive solutions, heated fluids, liquefied gases, viscous fluids, or slurries and pastes. If needed, optional materials such as Hastelloy C-276 are available on request.

1000HL Syringe Pump Features:

- Intrinsically safe design is UL/Demko approved for Class 1, Div 2 and Zone 2 locations.

Operating Modes:

- Constant Flow with up to three pumps.

- Constant Pressure with up to three pumps.

- Flow or Pressure Programming with a single pump.

- Continuous flow or pressure with dual pump.

External Interface:

- RS232 serial interface.

- Analog voltage inputs.

- Digital inputs and outputs.

1000HL Syringe Pump Applications:

- Metering and dispensing in experiments and pilot plants where explosive conditions may occur, but where ignitable concentrations of gases, vapors, or liquids are not likely to exist under normal operating conditions.

- Precision fluid addition in research and manufacturing processes.

- Reactant feed in chemical process development, catalyst evaluation, plastic formulation.

- Accurate metering of liquefied gases.