CAMSIZER P4 - Particle Size and Shape Analyzer

There is now a new version of this product, the CAMSIZER 3D - Particle Size and Shape Analyzer.

High quality and reproducibility of results no more work without this instrument

Particles analysis

High quality and reproducibility of results

Review Date: 9 Dec 2021 | Microtrac

Simple to use.

Measurement of powders

This product covers a very important area in materials analysis. Measurements are simple to make and it offers the possibility of expansion. A system like this can perform a large amount of measurements and, in the environmental sector, cover important market niches, such as working on the quantification of polluting particles (e.g. asbestos) in soils.

Review Date: 16 Mar 2020 | Microtrac

Cant go wrong with the Camsizer P4 or Retsch Technologies

Analysis of sieve gradation of sand

My company moved a CAMSIZER P4 and went about recommissioning it for our use. After resolving a few technical issues, we went about the task of correlating the results to those from a set of sieves which we were replacing. Our initial work resulted in a poor correlation to our existing results. To begin our trouble-shooting process, Retsch Technology remotely reviewed our measurement routines and result data by remote access using Team Viewer software. This confirmed the correctness of the CAMSIZER P4 results which were being generated. Having eliminated the CAMSIZER as the source of our problem, we then began a methodical examination. The sieving data was re-run and then compared to the CAMSIZER results in the CAMSIZER software. This comparison showed a reasonably close correlation with a maximum difference of <1.103%. Retsch Technology decided that a better fit could be achieved and the CAMSIZER software showed us how to do it. The two points which were cause for concern were the 40 mesh and the 25 mesh results (see below). In order to further investigate this, both sieves were subjected to additional vibratory energy, in this case, hand shaking. The result in both cases was additional material passing through the sieve of interest. When this amount was subtracted from the sieve of interest and was added to the next smaller sieve, the results fell right in line with the expected results from the CAMSIZER. In these experiments, the maximum difference was < 0.641%. Thus, the problem was identified to be the overloading of the individual sieves and sticking of near mesh grains to the wire mesh. I am truly amazed by the CAMSIZER’s ability to accurately measure the material. Not only can it accurately measure the material consistently, it can even tell you where your issue is, by the graphs it can produce. The CAMSIZER is truly an amazing machine and amazingly accurate. I highly recommend that all labs purchase a CAMSIZER if you want a very accurate world class measurement system for your COA’s.

Review Date: 8 Apr 2019 | Microtrac

I highly recommend for any and all particle size and shape analysis.

Particle size and shape analysis

Verder scientific has excellent customer service. Thier instrumentation is user friendly. I highly recommend for any and all particle size and shape analysis.

Review Date: 26 Mar 2019 | Microtrac

There is now a new version of this product, the CAMSIZER 3D - Particle Size and Shape Analyzer.

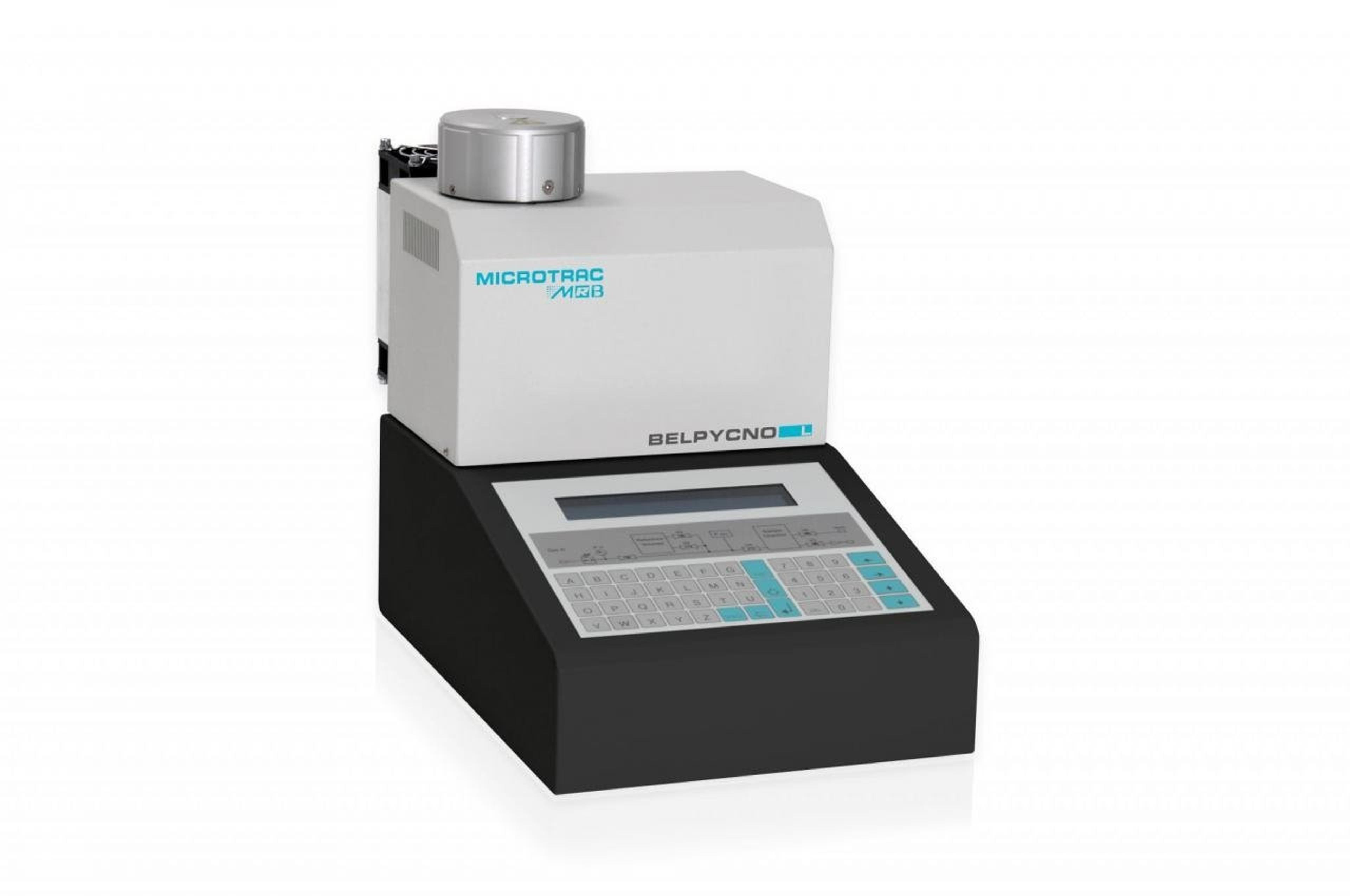

The CAMSIZER P4 is a compact dynamic image analyzer for simultaneous measurement of particle size distribution, particle shape and additional parameters of powders and granules in the range from 20 µm to 30 mm (ISO 13322-2).

Based on the unique dual camera technology, the CAMSIZER P4 provides extremely sharp images and determines a variety of different size and shape parameters for each detected particle. Thanks to analysis of hundreds of thousands or even millions of individual particles, results with high statistical reliability are guaranteed. The typical measurement time is only 1 to 3 minutes with 60 images being evaluated per second in real time.

Further benefits include simple operation, a robust and maintenance-free instrument as well as stable and reliable measurement results even if operated 24/7. In combination with the optional AutoSampler efficiency can be increased by high sample throughput due to automated sample measurement.

The CAMSIZER P4 is ideally suited to replace error-prone sieve analysis. The results produced by both techniques can be made to match so that product specifications based on sieve analysis remain unchanged. Users of image analysis benefit from reduced workload, higher sample throughput and more detailed results.