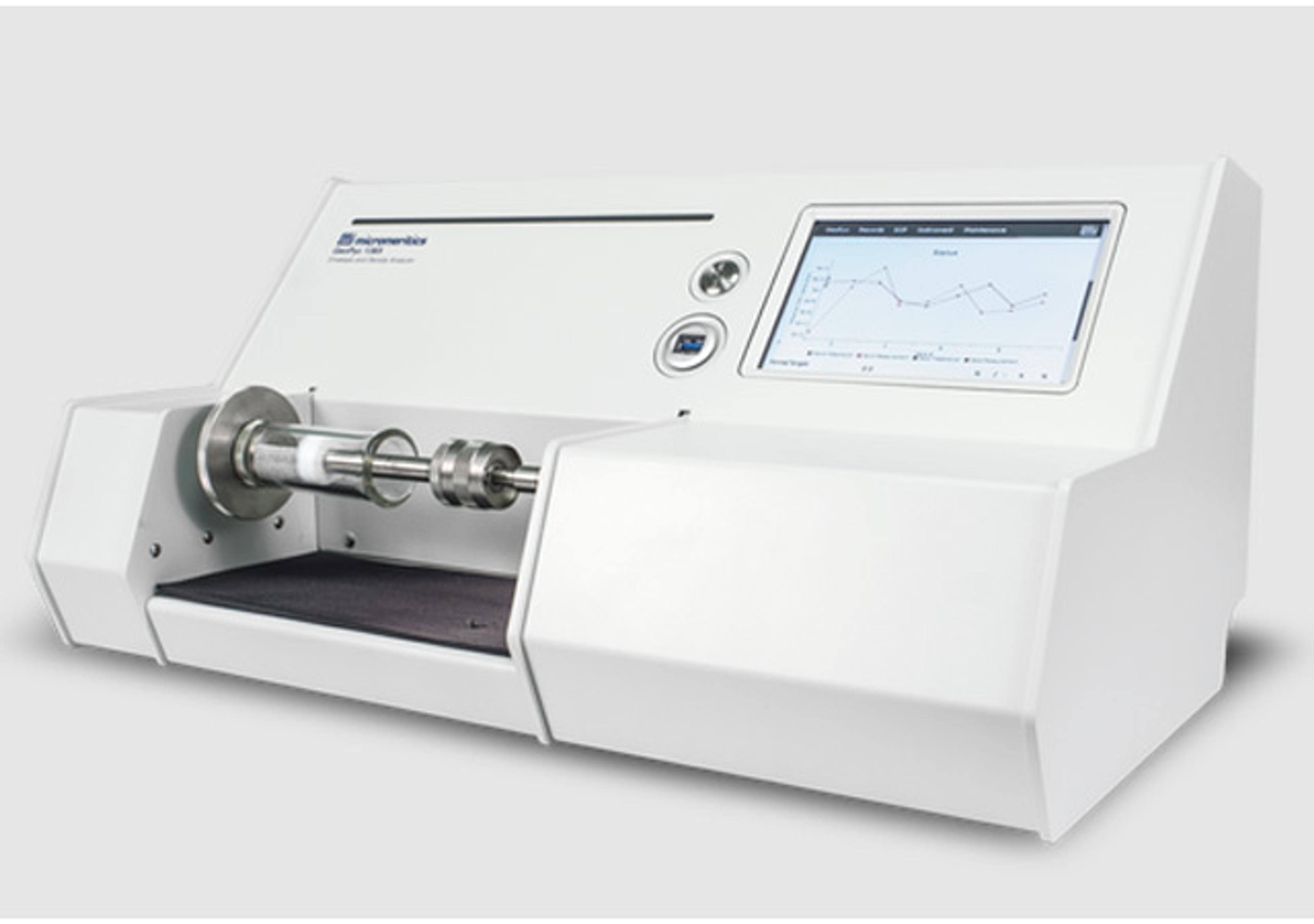

CCS-2100 Automatic Cold-Cranking Simulator

CCS-2100 Automatic Cold-Cranking Simulator • Cooled by Built-in Solid-State Thermoelectric Modules • Improved Precision Over Earlier Models • Powerful VISCPRO® for Windows® Software • Fully Automatic Operation • Extended Range – 900 to 25,000 mPa·s (cP) • Needs No Solvent Cleaning CANNON Thermoelectrically-Cooled Cold-Cranking Simulators measure the apparent viscosity of oils at temperatures from –35°C to –5°C within a viscosi…

The supplier does not provide quotations for this product through SelectScience. You can search for similar products in our Product Directory.

CCS-2100 Automatic

Cold-Cranking Simulator

• Cooled by Built-in Solid-State Thermoelectric Modules

• Improved Precision Over Earlier Models

• Powerful VISCPRO® for Windows® Software

• Fully Automatic Operation

• Extended Range – 900 to 25,000 mPa·s (cP)

• Needs No Solvent Cleaning

CANNON Thermoelectrically-Cooled Cold-Cranking Simulators measure the apparent viscosity of oils at temperatures from –35°C to –5°C within a viscosity range of 900 mPa·s to 25,000 mPa·s. The CCS-2100 combines automatic sample loading, computer-controlled operation, and solvent-free cleaning to permit completely unattended operation. No further operator involvement is required after initial loading of the sample table and identification of samples. The CCS-2100 will automatically test up to 30 samples at one time, calculate their viscosities, and record the results, freeing the operator for other tasks. Improved temperature management of the rotor/stator eliminates the need for grouping the samples by temperature of analysis, as was necessary in older CCS models. In addition, a thermoelectric sample warming cycle greatly improves the sample flushing process. The CCS-2100 meets all the requirements of ASTM D 5293 and SAE J300.

The CCS-2100 consists of a patented thermoelectrically-cooled rotor/stator, a Sample Table with capacity for 30 oil samples, and an integral CCS Series II Controller. The rotor/stator cell is attached to a vacuum system and a metering constant-displacement injection pump. The rotor/stator cell is cleaned by purging the previously measured sample with a portion of new sample prior to measuring its viscosity. Purged sample is drawn into a waste receiver by the vacuum system. Rotor speed is measured by a high resolution digital encoder. A proprietary software program then converts this data to sample viscosity. Viscosity calculations are based on test data and rotor/stator calibration information stored by the software. User interface options include an instrument calibration routine, configuration of test cycles, and multiple means of processing test data including save, print, and export via the RS-232 serial port for LIMS capture.