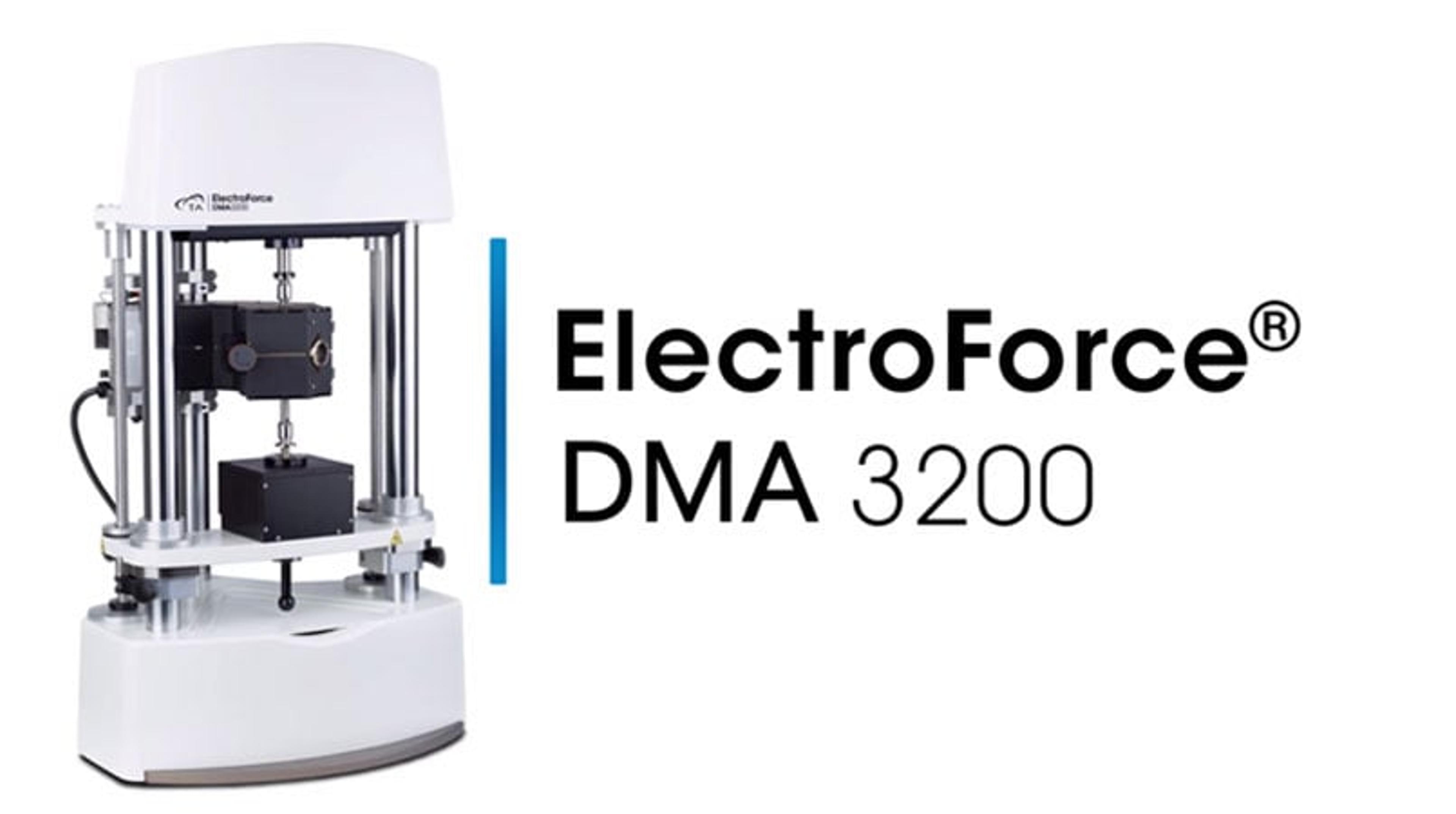

DMA 3200 High Force DMA

The DMA 3200 combines decades of cutting-edge fatigue and world-leading Dynamic Mechanical Analysis technologies into a unique and highly versatile testing platform. The patented, frictionless Electroforce ® motor technology, superior mechanical design, efficient environmental control, and wide variety of clamping systems deliver superior data accuracy for the broadest range of applications.

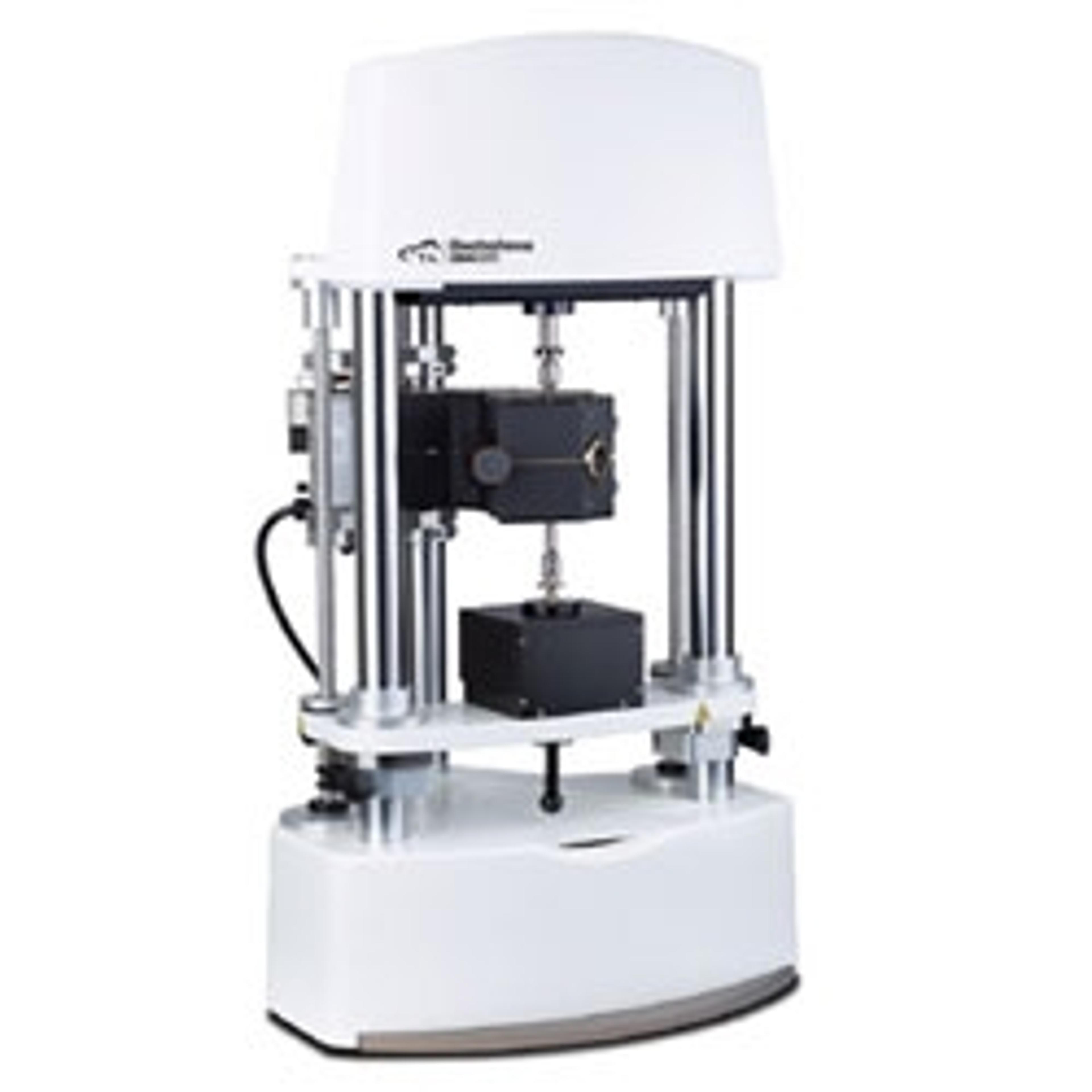

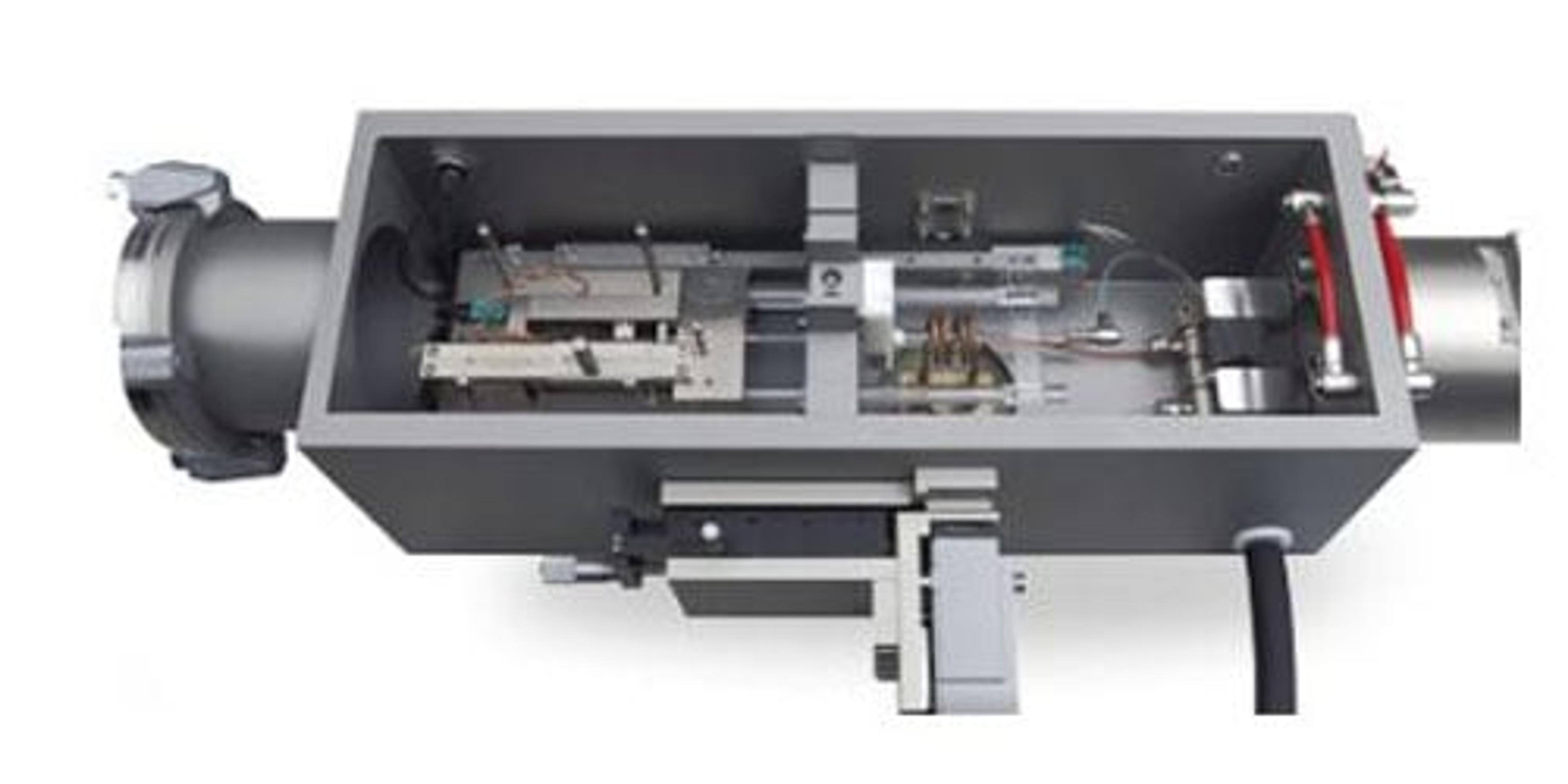

The DMA 3200 features patented ElectroForce linear motor technology enabling a single instrument to deliver unequalled performance and data accuracy. This unique motor technology combines powerful rare-earth magnets with a frictionless flexural suspension for the most precise force and displacement control over a wide range of frequencies and amplitudes. The DMA 3200 motor delivers a force output of up to 500 N and controlled displacements ranging from 1 micron to 13 mm. Testing can be conducted in both static and dynamic modes.

In addition, the frictionless, moving-magnet design eliminates failure points that exist in other motor designs, such as moving wires and bearing degradation. This ensures the most durable and reliable performance; proven over billions of cycles through decades of maintenance-free use in ElectroForce fatigue test instruments. It is the only motor in the industry backed by a ten-year warranty.

This efficient, quiet, and lubrication-free motor technology allows the DMA 3200 to be used virtually anywhere; from lab to production floor, or from the cleanroom to office space.

Key Features

- Patented, linear motor and high-resolution displacement sensor provides unmatched control over the widest ranges of force, displacement, and frequency, for superior data accuracy

- Ultra-durable, frictionless motor, backed by industry’s only ten-year warranty, provides maintenance- and worry-free operation

- High force of 500 N enables testing of larger samples or final parts under real-world conditions, by achieving higher loading levels in both DMA and fatigue analysis

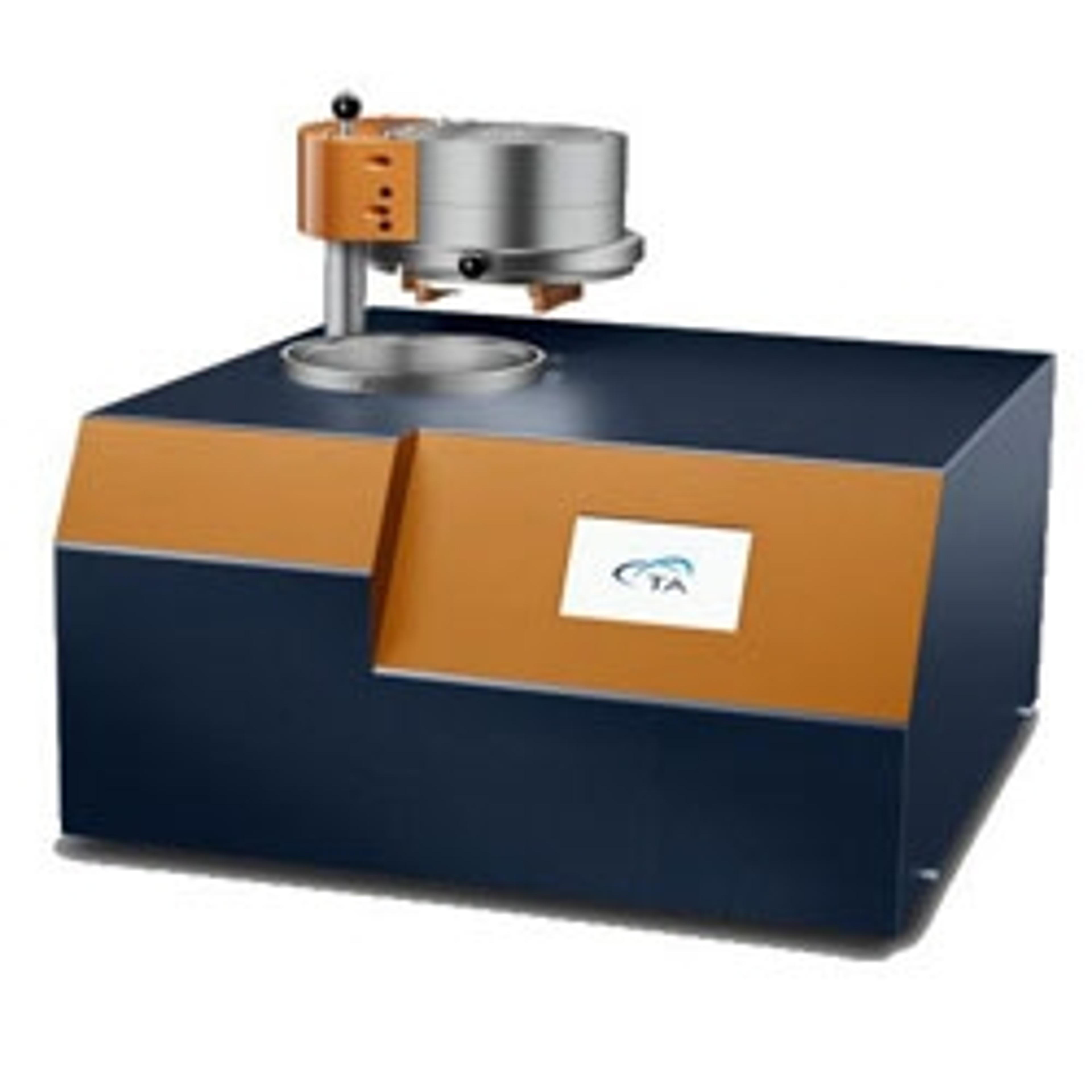

- Forced Convection Oven (FCO) provides superior control and responsiveness over a temperature range of -150°C to 600°C for the highest degree of accuracy and flexibility in experiment thermal profiles

- Large Sample Oven (LSO), with a temperature range of -150°C to 315°C, offers spacious interior dimensions to accommodate testing of large samples or components

- Air Chiller Systems (ACS) offer unique gas flow cooling for sub-ambient testing without the use of liquid nitrogen, eliminating potential laboratory hazards while providing an incredible return on investment

- Broad range of fixtures accommodate a wide range of sample sizes and geometries adding to testing versatility

- Extremely rigid test frame and air bearings ensure the most accurate results on samples of very high stiffness

- Multi-color status lights provide clear and visible indication of instrument and test status

- WinTest® and TRIOS Software packages provide powerful and easy-to-use instrument control and data analysis for the ultimate flexibility in experimental design.