Quenching Dilatometers 805 ADT, 805A, 805L, 805A/D

Quenching dilatometers are used to study the heat treatment of steel and metal alloys, helping to identifying the heating rate, quenching rate, and isothermal dwell times necessary in metals manufacturing to yield the crystalline structure necessary to meet the required physical properties of the finished product.

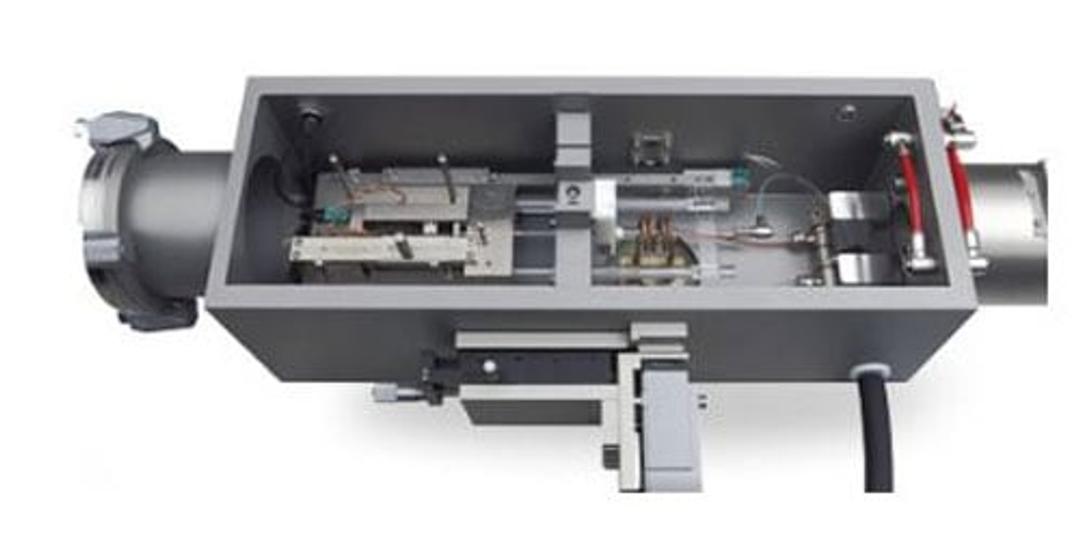

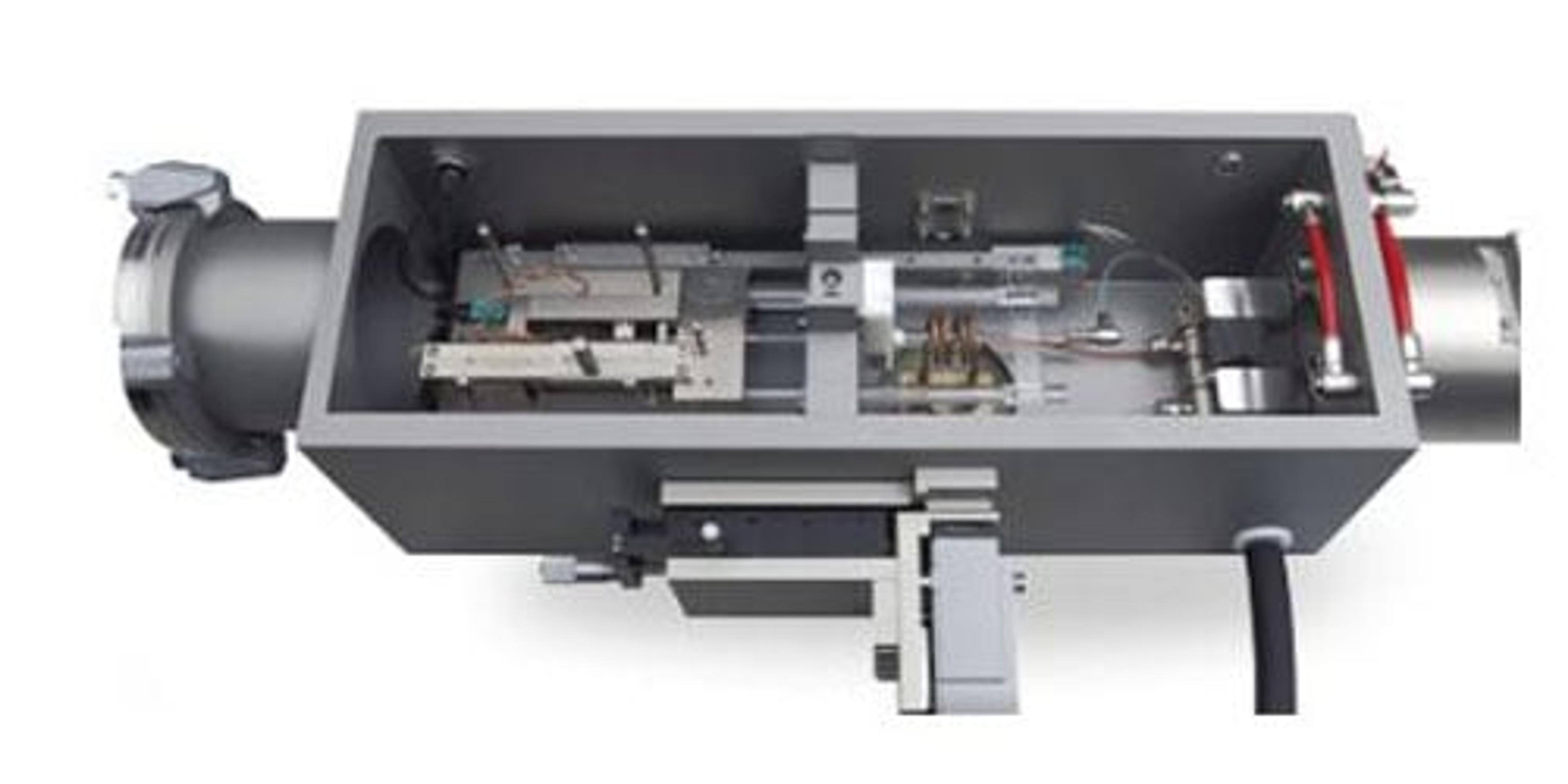

The DIL805 Series comprises of four models: DIL 805L, DIL 805A are quenching dilatometers, DIL 805A/D is a quenching with the capability to deform the specimen by compression, and DIL 805A/D/T that can also stretch it in tension mode.

All four instruments are fully automated, self-contained units used to measure dimensional changes under extreme conditions of controlled heating and cooling.

In the quenching mode the sample, solid or hollow, is inductively heated to a temperature plateau and is then cooled at a user-defined (linear or exponential) cooling rate. The phase transformation occurring in the continuous cooling process or in the isothermal dwell, with or without compression/tensile stress, is indicated by the measured change in length. An array of cooling or isothermal curves represents a continuous-cooling-transformation (CCT) diagram or an isothermal time-temperature-transformation (TTT) diagram, respectively. DIL 805A represents today the benchmark for determining these dimensional changes and phase transitions. Operating from -160°C up to 1500°C (in two different furnace configurations) with heating rates of up to 4000°C/s and cooling rates of 2500°C/s, can closely simulate the material response for any production or heat treatment process.

The DIL 805A/D, on top of the quenching mode, is distinguished by its capability to deform the specimen with controlled deformation rates of 0.01 to 200 mm/s. Used to optimize steel processes like hot or cold rolling, DIL 805A/D allows to develop time-temperature-transformation diagrams after deformation (DTTT) and is also used to examine creep and relaxation processes.

DIL 805A/D/T further extends the capabilities to alternate tensile and compressive loading to emulate mill processing. Moreover, tensile loading to fracture lends additional information about material’s final performance and allows to generate true-stress vs true-strain or stress/strain cycling plots.