Dynamic Mechanical Analyzer

No one sells more DMA’s than TA Instruments. Utilizing the latest technological breakthroughs TA Instruments DMA’s provide the best performance and ease-of-use.

Dynamic Mechanical Analysis measures the mechanical properties of materials as a function of time, temperature, and frequency. In addition to basic material properties, DMA also quantifies finished part characteristics, reflecting the important contribution that processing has on end-use performance. DMA is commonly used to measure glass transition temperatures and secondary transitions, orientation caused by processing, cold crystallization, cure optimization, filler effects in composites, and much more. DMA provides an accurate measure of material stiffness (modulus) but also other important mechanical properties such as damping, creep, and stress relaxation.

TA Instruments is the world leader in Dynamic Mechanical Analysis, offering two state-of-the art dedicated DMA instruments and additional DMA capability through our rheometers and mechanical test instruments. All TA Instruments DMA products feature innovative technology for force and displacement measurements, temperature control and accuracy, instrument stiffness, and ease-of-use.

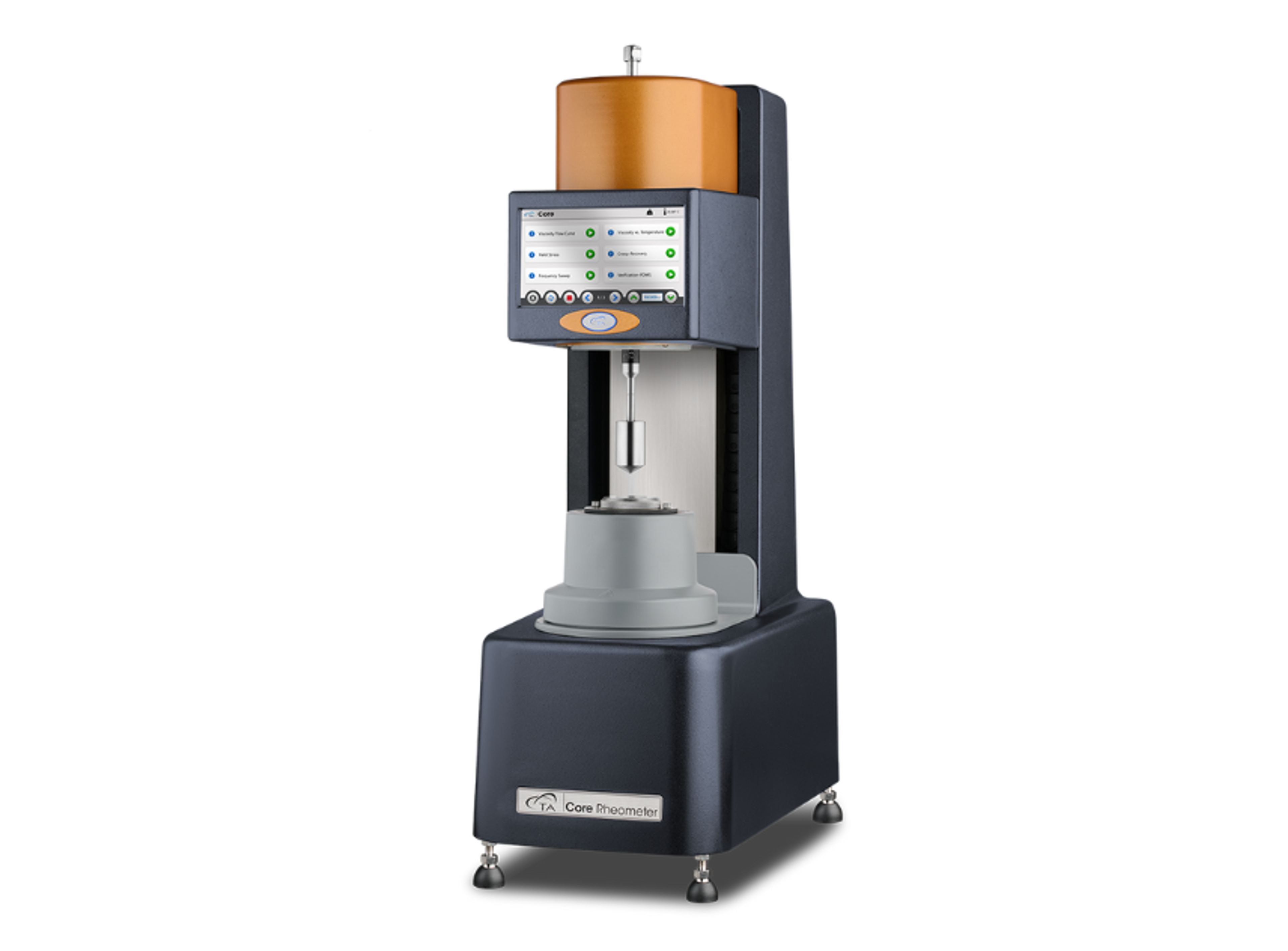

DMA 850

TA Instruments invites you to experience the ultimate in Dynamic Mechanical Analyzers, the Discovery DMA 850. Building on superior technologies of the world’s best-selling DMA, improvements in every aspect of DMA performance deliver the most accurate and reproducible measurement of mechanical properties over a wide temperature range. It’s never been easier to get great DMA data!

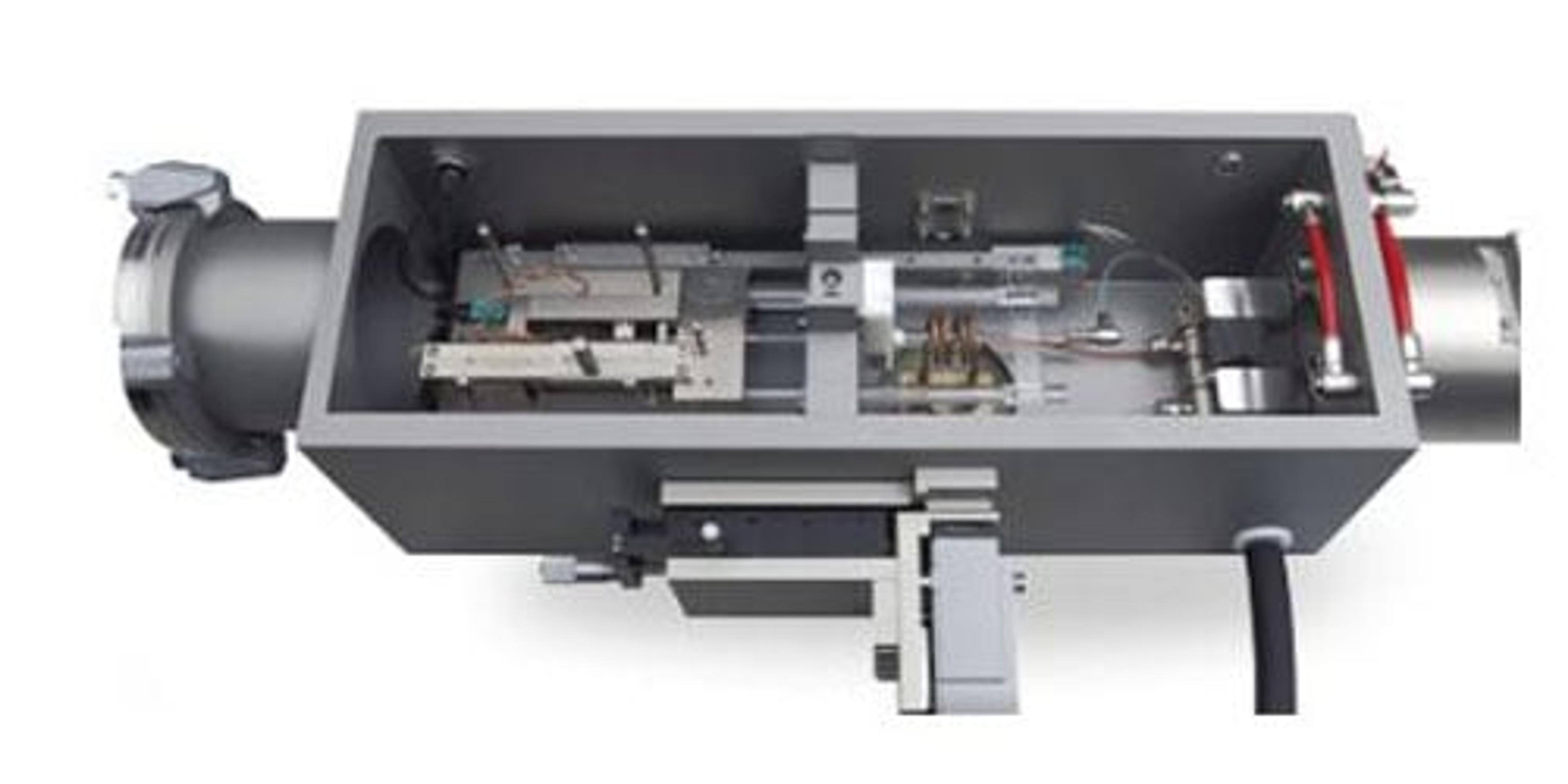

ElectroForce DMA 3200 High Force DMA

The DMA 3200 features patented ElectroForce linear motor technology enabling a single instrument to deliver unequalled performance and data accuracy. This unique motor technology combines powerful rare-earth magnets with a frictionless flexural suspension for the most precise force and displacement control over a wide range of frequencies and amplitudes. The DMA 3200 motor delivers a force output of up to 500 N and controlled displacements ranging from 1 micron to 13 mm. Testing can be conducted in both static and dynamic modes.

In addition, the frictionless, moving-magnet design eliminates failure points that exist in other motor designs, such as moving wires and bearing degradation. This ensures the most durable and reliable performance; proven over billions of cycles through decades of maintenance-free use in ElectroForce fatigue test instruments. It is the only motor in the industry backed by a ten-year warranty.

This efficient, quiet, and lubrication-free motor technology allows the DMA 3200 to be used virtually anywhere; from lab to production floor, or from the cleanroom to office space.

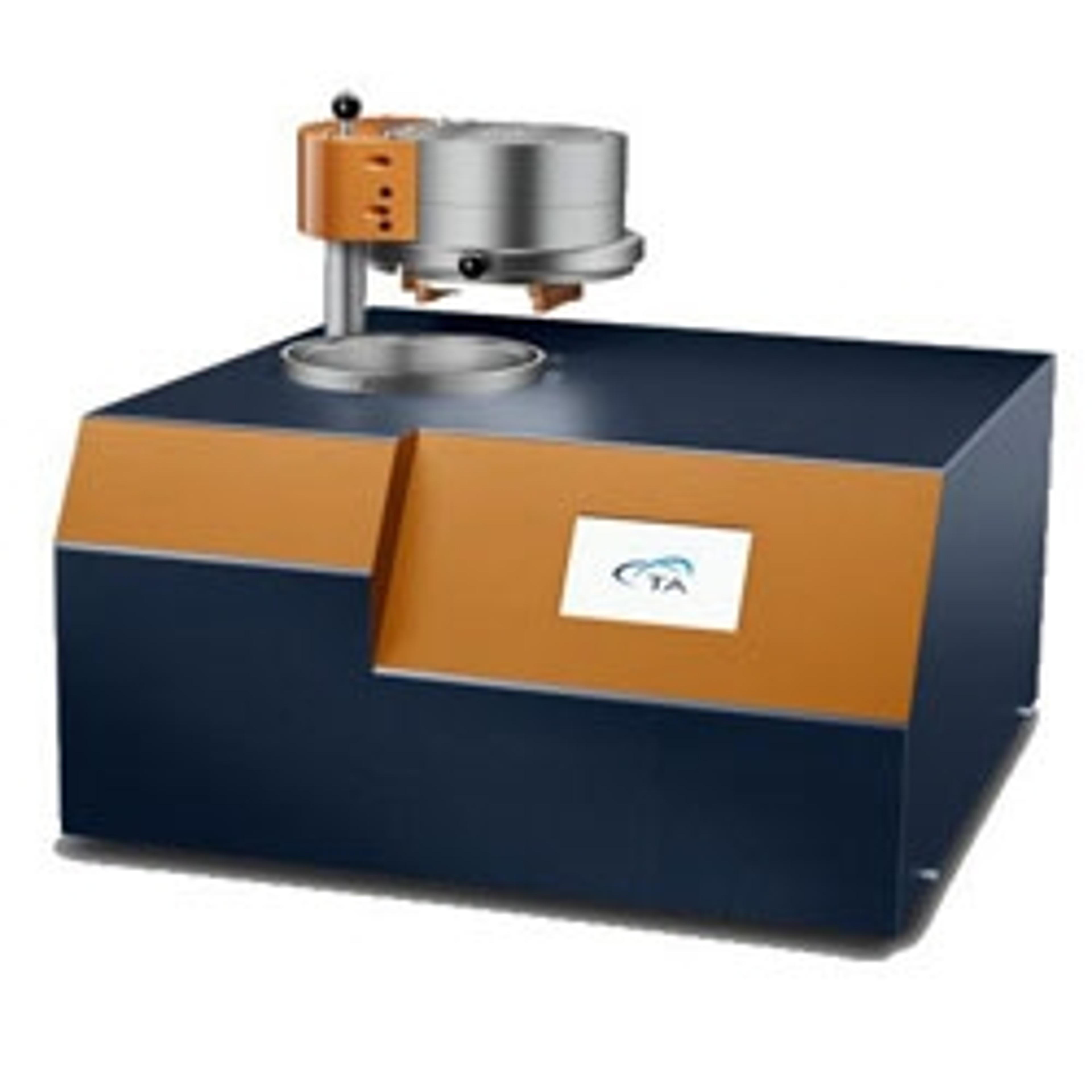

RSA-G2 Solids Analyzer

The new RSA-G2 is the most advanced platform for mechanical analysis of solids. The separate motor and transducer technology of the RSA-G2 insures the purest mechanical data through independent control of deformation and measurement of stress. It is capable of performing the most accurate DMA measurements as well as many additional experiments including creep and recovery, stress relaxation, stress ramps, strain rate ramps, iso-strain, iso-force, fatigue, multi-wave, arbitrary waveform, and dielectric thermal analysis. With such a broad range of solid analysis techniques, the RSA-G2 is uniquely positioned to address the widest range of applications from the R&D bench to the quality control lab. This new high-performance instrument represents the fourth generation of dual head mechanical analyzers, featuring a new force convection oven for precise and accurate temperature control, extensive array of geometries to accommodate the widest range of sample shapes and stiffness, and immersion testing capability. In addition, the RSA-G2 doubles as a DETA, or Dielectric Thermal Analyzer, for stand-alone or simultaneous measurements.