How to accelerate drug discovery with optimized high-throughput screening

Antibody expert, Dr. Chelcie Eller, shares how to achieve reliable and reproducible high-throughput drug and biomarker screening

15 Jul 2021

In this SelectScience article, we speak with Dr. Chelcie Eller, team lead for the FirePlex New Product Development at Abcam. Eller’s team is responsible for merging Abcam’s recombinant in-house antibody pipeline with the FirePlex screening platform - identifying antibody pairs and extensively validating multiplex immunoassay panels.

Here, Eller shares her expert insight into the current drug discovery landscape, including persisting challenges, important considerations, and how to best ensure reproducibility and robustness in your high-throughput screening assays.

What challenges are scientists facing with biomarker and drug screening?

CE: The biggest concerns for the discovery process are time and money. The drug development pipeline is typically a lengthy and costly process where, for every 10,000 to 100,000s compounds screened, after anywhere from 11 to 16 years, only one new drug may get approval and make it to market. The initial stage of lead generation often takes three to five years, where only several hundred drug candidates then enter into preclinical toxicity assessment.

In addition, candidate compound failures, whether due to pharmacokinetics, lack of efficacy, animal toxicity, or adverse effects in humans, are ideally caught early in the drug discovery process either through more predictive and validated biomarker screening or by using high-throughput screening (HTS) – a robust approach to facilitating more rapid lead generation.

What are the most important factors to consider when choosing an assay for high-throughput screening?

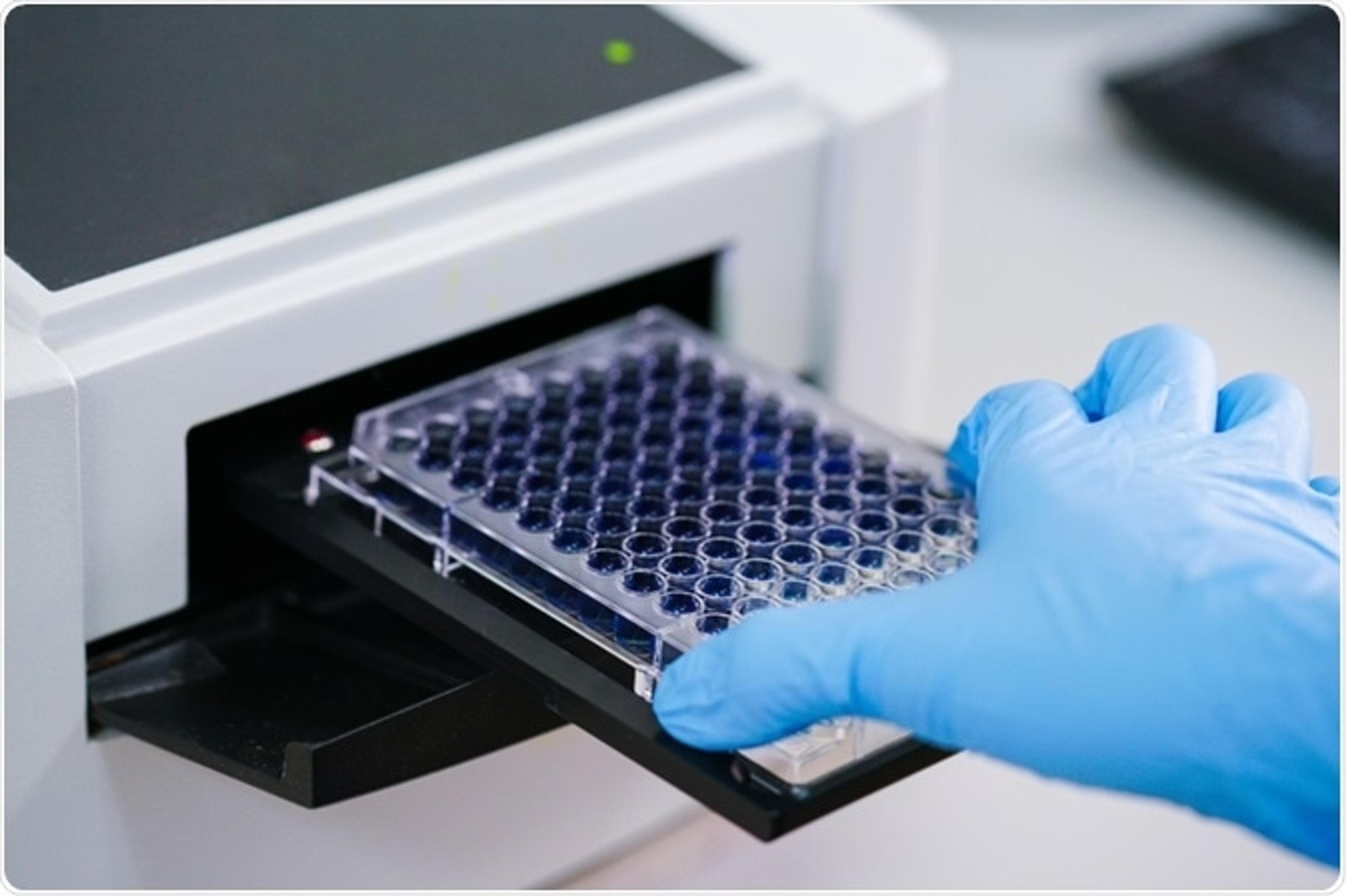

CE: Often, the drug discovery process begins with lead optimization that relies on HTS to narrow down numerous compounds to just a few promising candidates. To do this in a timely and cost-effective manner, HTS relies on a scalable and high-quality assay format. To aid scalability, multiplexing HTS offers a rapid approach to exponentially increase the number of data points collected. This is where our FirePlex immunoassays come into play.

For example, our FirePlex-384 immunoassays allows screening of up to 10 analytes per well in a 384-well plate, which is 3,840 data points per plate, and our novel FirePlex-1536 immunoassay platform can screen up to five analytes per well in a 1536-well plate, generating 7,680 data points per plate. Both are no-wash assays, which creates a simplified workflow that reduces variability in assay execution and is much easier to automate. The data is then rapidly collected on a high-content imager and can be saved and rescanned, providing high-quality data. By offering a new, more effective biomarker analysis workflow, FirePlex immunoassays enable data-driven R&D to guide the most effective strategies and minimize the risk of late-stage failures.

Why is using high-quality antibody pairs essential to ensure assay reproducibility?

CE: While having increased data points is valuable, HTS immunoassays quintessentially require high accuracy. Often, plates are run in one-shot approaches, so false positives and negatives can waste time on a false lead or miss promising drug candidates that could save lives.

Our FirePlex technology utilizes Abcam's extensive catalog of high-quality recombinant antibodies. These antibodies not only have high affinity and specificity to their target, as they're validated throughout the screening and selection process, but the antibody engineering also reduces background and non-specific signal, which maximizes sensitivity. Finally, the recombinant expression of antibodies is controlled and reliable, avoiding problems associated with hybridoma antibody production such as gene loss, gene mutations, and cell line drift. So the manufacturing of Abcam's recombinant antibodies demonstrates outstanding batch-to-batch consistency, which gives the highly reproducible results required by drug development research. These antibody pairs are so reliable that they've been incorporated into multiple product lines, not only FirePlex.

What quality assessments are performed to ensure robustness in the assay?

CE: Multipled HTS presents additional challenges due to the increased presence of many more antibody pairs. Our FirePlex panels undergo extensive cross-reactivity testing to prove that the pairs are all exhibiting specificity and compatibility. We also assess highly conserved protein family members for any cross-reactivity or interference, confirm specificity and validate biological sample types, and benchmark biological data from singleplex and published literature values.

Our team also evaluates matrix effects by testing native biological linearity, parallelism, and spike recovery. The complete validation process takes longer than we see for a traditional singleplex ELISA development but creates the confidence needed for a robust multiplex assay. It's essential that we have confidence in our antibody pairs.

What are the benefits and limitations of using a no-wash assay?

CE: A no-wash assay workflow reduces the number of steps between reagent handling and final data collection. This eases assay setup and allows to implement automation, which not only reduces potential errors but also speeds up the scale-up, which can be a critical factor when assessing HTS. In terms of the limitations of a no-wash workflow, sensitivity may be reduced. Generally, wash steps reduce background, thereby increasing signal-to-noise, particularly on the low limit of quantitation. However, the use of high-affinity antibodies can alleviate some loss of sensitivity.

We also offer a higher-plex FirePlex-96 platform that can detect up to 70 analytes at once to complement our HTS platform. This FirePlex-96 platform uses the same high-quality recombinant antibodies and incorporates wash steps to maximize pair sensitivity. We often find that the FirePlex-96 wash assay is much more applicable for biomarker discovery and incorporating biomarker comparison across multiple sample types.

How does Abcam's portfolio aim to help overcome existing challenges in screening?

CE: We see a lot of potential in expanding the catalog portfolio for the FirePlex-1536. Due to the exponential increase of data points collected, it can offer a scalable assay format. Abcam is in a powerful position to incorporate these high quality antibody pairs into multiple different product types.

So, there's a lot of synergy, depending on the needs of the customer. Typically, researchers in academic settings may lean more heavily on our SimpleStep ELISA platform, whereas we see pharmaceutical companies using HTS with FirePlex more.

I think one of the standout features of the FirePlex platform is that it's instrument-agnostic. On the Abcam website, we have a list of validated instrument types. Still, we try to democratize multiplexing and make it more user-friendly and available to everyone regardless of their instrumentation. This includes a free software suite to complement some of the heavy lifting required for data collection from a single plate, especially with the rollout of the new 1536 platform.

Learn more from the experts at Abcam in our exclusive interview series:

- Confidence in your knock-outs: The importance of robustly validated cell lines – Dr. Julie Wickenden

- How to achieve research success with knock-out models – Dr. Hanna Dreja

- Speeding the transition from bench to bedside with CRISPR/Cas9 – Dr. Karine Enesa

- Breakthroughs in guide RNA: Creating successful CRISPR-Cas9 knock-outs – Dr. Yongwon Kwon