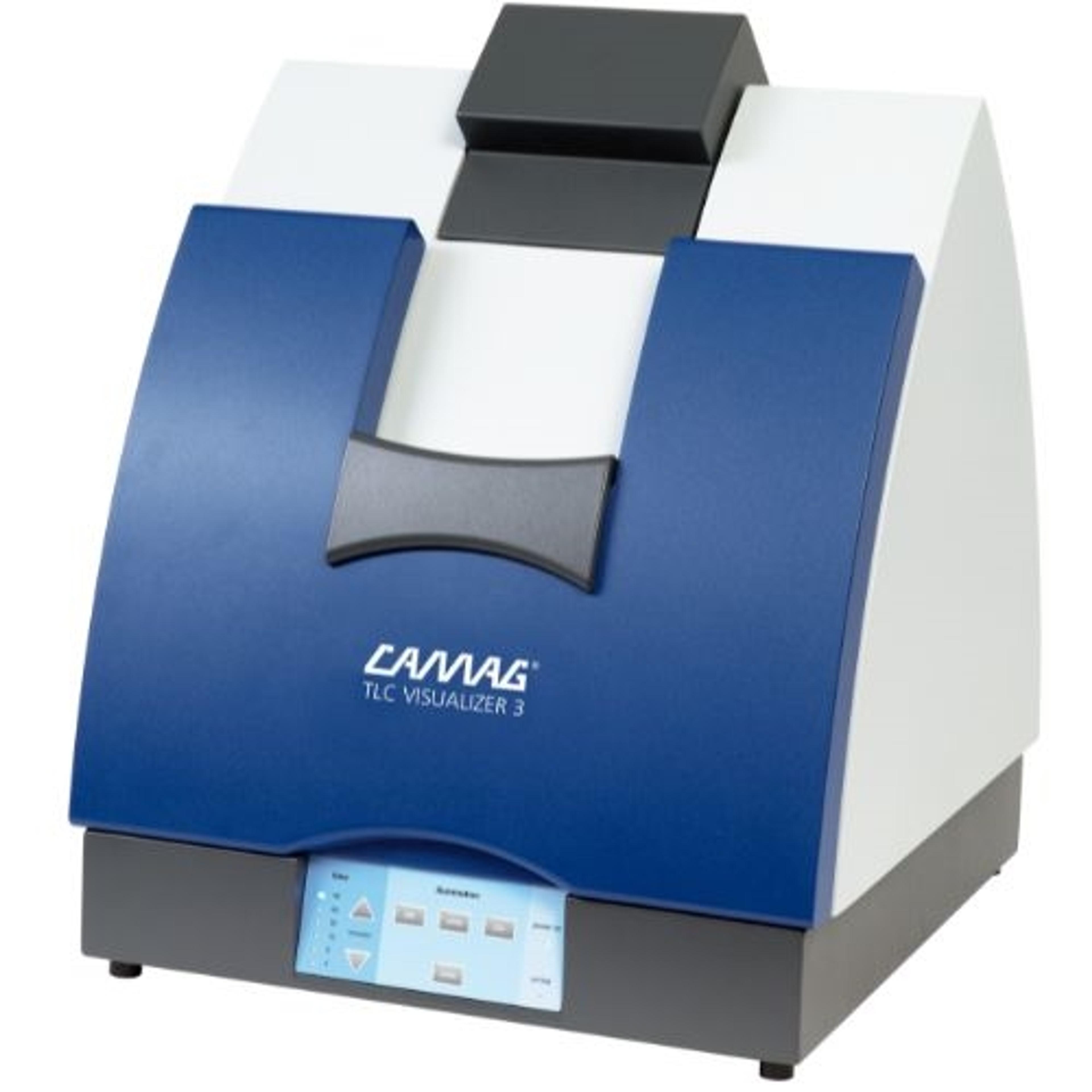

HPTLC PRO Module DERIVATIZATION

Derivatization is often used to visualize specific substance classes after separation on HPTLC glass plates (20 x 10 cm). Due to its unique and patented “micro droplet” spraying technology, the fully-automated HPTLC PRO Module DERIVATIZATION ensures homogeneity and reproducibility in applying derivatization reagents.

The HPTLC PRO Module DERIVATIZATION is part of the CAMAG® HPTLC PRO SYSTEM – the first fully automated HPTLC system worldwide.

The HPTLC PRO Module DERIVATIZATION is designed for the fully automatic derivatization of HPTLC glass plates (20 x 10 cm) and uniquely combines two steps in a single device: high-precision spraying of derivatization reagents and heating of the plate. Employing the patented micro-droplet spraying technology, the Module DERIVATIZATION enables maximum homogeneity in applying derivatization reagents. The integrated plate heating unit ensures a uniform heat distribution across the plate.

To suit the viscosity of the spraying reagents, four different nozzles are available. Spraying at slightly reduced pressure further improves the spraying process. Equipped with a fully automated nozzle changer and cleaning station, the Module DERIVATIZATION effectively avoids cross-contamination.

Key Features

- Part of the fully automated HPTLC PRO SYSTEM

- Nozzle changer to choose nozzles from three different nozzle parking positions

- Integrated plate heating unit

- Handling of two different reagents

- HPTLC glass plates (20 x 10 cm)

- Software-controlled by visionCATS

Key Benefits

- Spraying and heating in a single device

- Maximum homogeneity in reagent and heat distribution

- Highest user safety through automation and fume hood connection

- Optimal cleaning procedure between nozzle changes

- Low reagent consumption (3 mL)